500, 750 SERIES, 650, GB/GW-300 specifications

The A.O. Smith GB/GW-300, 650, 750 Series, and 500 represent a cutting-edge line of commercial water heaters designed to meet the diverse needs of various applications. These models are highly regarded for their advanced features, robust construction, and reliable performance, making them ideal for businesses such as restaurants, hotels, and industrial facilities.One of the main features of the A.O. Smith GB/GW series is its high-efficiency design. These water heaters are built with advanced insulation and heat exchanger technology, which contribute to reduced energy consumption and lower operating costs. The products achieve notable energy efficiency ratings, ensuring that businesses can maintain their hot water supply without incurring excessive utility bills.

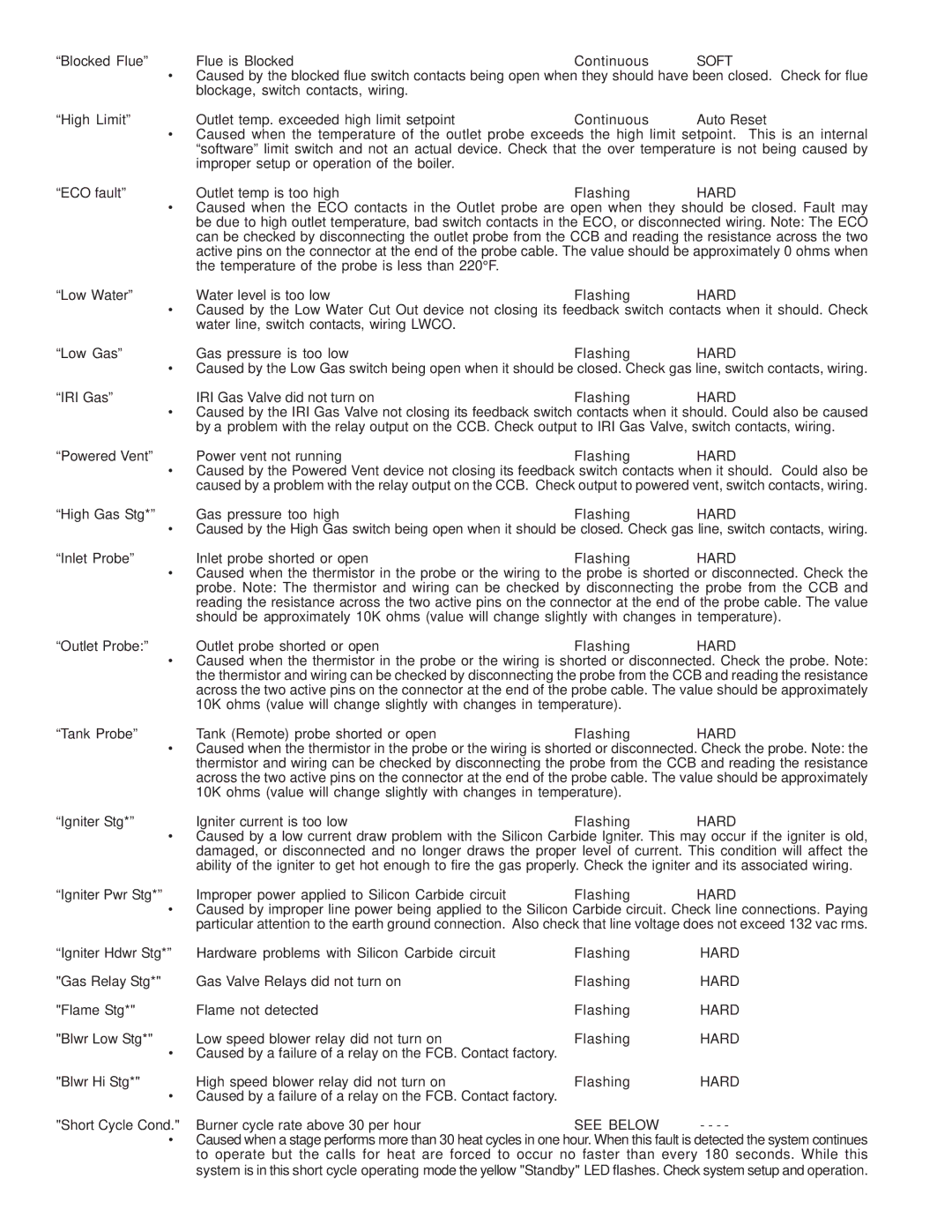

The GB/GW series also incorporates a user-friendly digital control system. This technology allows operators to monitor and adjust settings easily, providing real-time feedback on temperature and energy consumption. This level of control enhances operational efficiency and ensures hot water is always available when needed.

Another significant characteristic of the A.O. Smith GB/GW series is its durable construction. The units are designed with high-quality materials that resist corrosion and wear, extending their operational lifespan. The stainless steel tanks and heat exchangers are engineered to withstand high temperatures and pressure, making them reliable even in demanding environments.

Moreover, safety features are paramount in the design of these water heaters. The series includes multiple safety mechanisms, such as high-temperature limit switches and pressure relief valves, ensuring the safe operation of the unit at all times. This not only protects the equipment but also guarantees the safety of personnel using hot water.

The GB/GW series ranges in capacity, accommodating different sizes of operations. From the compact and efficient 300 model to the larger 650 and 750 units, the series offers flexibility to suit various demands. The 500 model strikes a balance between capacity and efficiency, making it a popular choice for medium-sized establishments.

In summary, the A.O. Smith GB/GW-300, 650, 750 Series, and 500 are exemplary choices for commercial water heating solutions. Their combination of efficiency, advanced technology, durable design, and comprehensive safety features ensures that businesses have access to reliable hot water, ultimately supporting their operational needs and enhancing service delivery.