MAINTENANCE

Daily Maintenance

Regular maintenance of your loader and hydraulic system will insure maximum loader efficiency and long life.

Never work under the Implement, the framework, or any lifted component unless the Implement is securely supported or blocked up to prevent sudden or inadvertent falling which could cause serious injury or even death.

NEVER perform maintenance beneath a raised loader unless loader is properly supported to prevent accidental lowering.

1.Check fluid level of tractor hydraulic system before starting each day’s operation. If necessary, add hydraulic oil as recommended in your tractor operator’s manual.

2.Daily, unless conditions justify more frequent greasing, lubricate all twelve grease fittings; one at each end of lift boom arms and one at rod and base ends of each lift and bucket cylinder.

3.After every ten hours of operation, check all hardware and tighten where required.

4.Replace hoses immediately if they are damaged by a cut or scrape, extruded at the fittings or leaking. Hydraulic oil leaks should be repaired promptly to avoid loss of oil and serious personal injury from escaping oil.

Escaping hydraulic fluid under pressure can penetrate skin, causing serious personal injury.

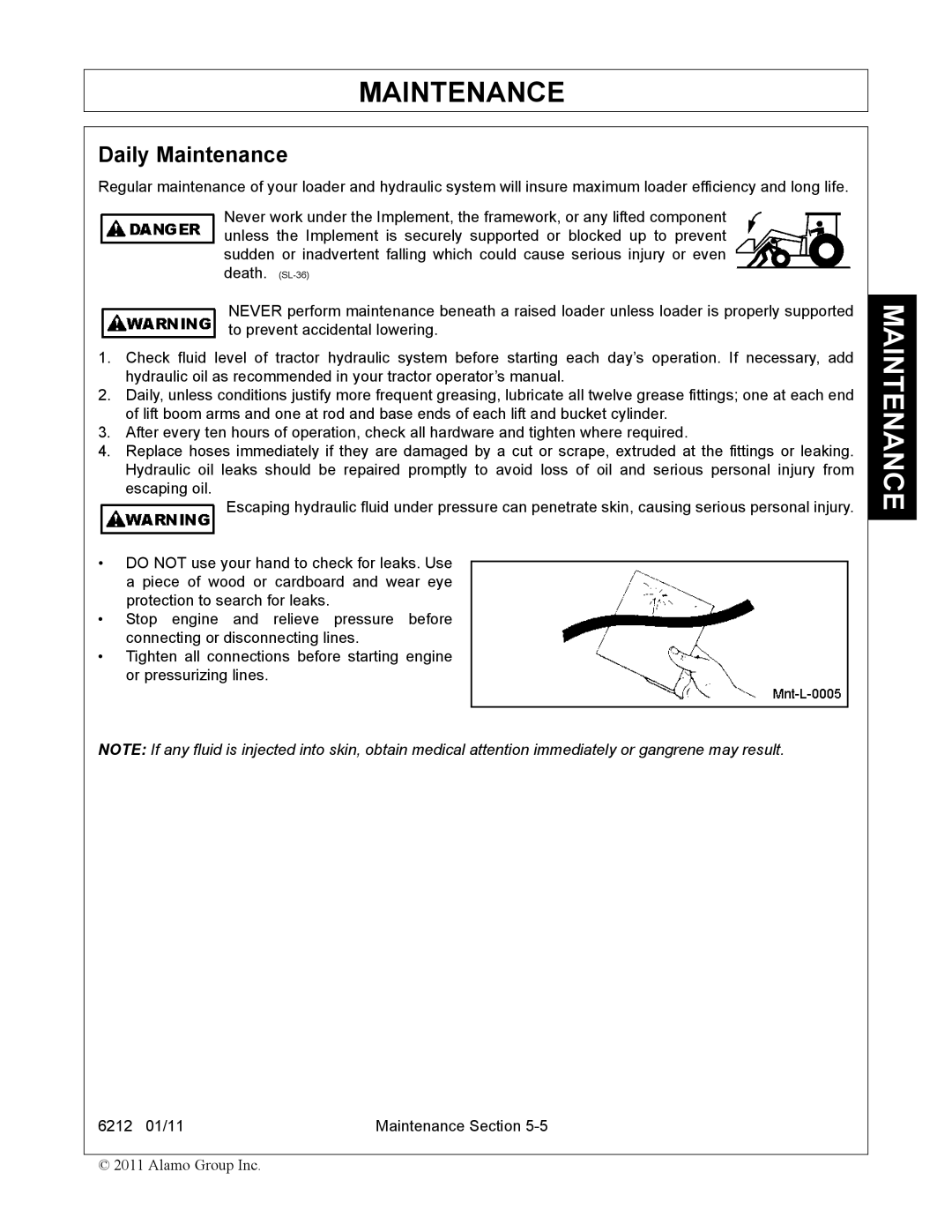

•DO NOT use your hand to check for leaks. Use a piece of wood or cardboard and wear eye protection to search for leaks.

•Stop engine and relieve pressure before connecting or disconnecting lines.

•Tighten all connections before starting engine or pressurizing lines.

NOTE: If any fluid is injected into skin, obtain medical attention immediately or gangrene may result.

6212 01/11 | Maintenance Section |

© 2011 Alamo Group Inc.