MAINTENANCE

MAINTENANCE

GENERAL

Before operating your DB150, make sure it is properly lubricated and thoroughly inspected. Only a minimum of time and effort is required to regularly lubricated and maintain this machine to provide long life and trouble free operation.

LUBRICATION INFORMATION

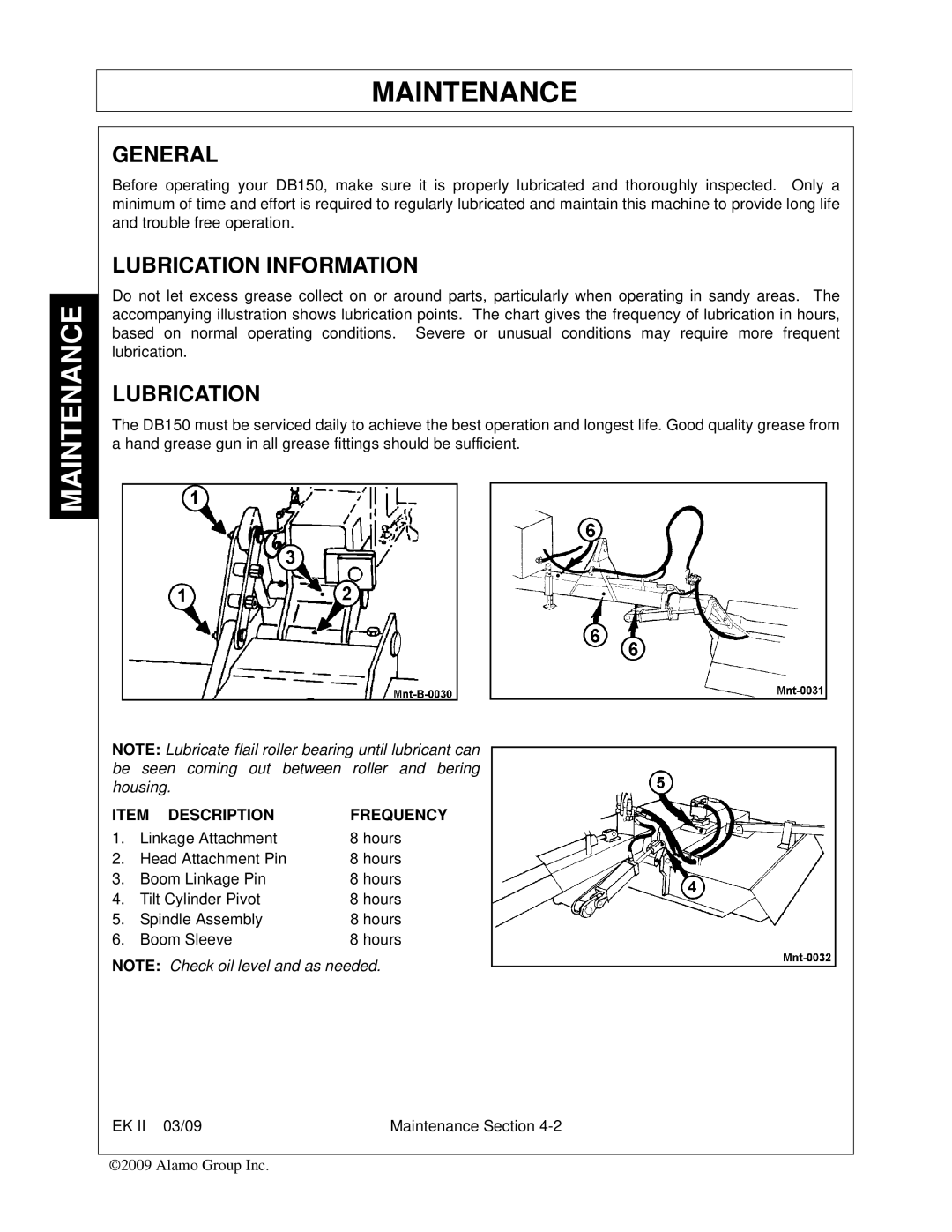

Do not let excess grease collect on or around parts, particularly when operating in sandy areas. The accompanying illustration shows lubrication points. The chart gives the frequency of lubrication in hours, based on normal operating conditions. Severe or unusual conditions may require more frequent lubrication.

LUBRICATION

The DB150 must be serviced daily to achieve the best operation and longest life. Good quality grease from a hand grease gun in all grease fittings should be sufficient.

NOTE: Lubricate flail roller bearing until lubricant can be seen coming out between roller and bering housing.

ITEM DESCRIPTION | FREQUENCY | |

1. | Linkage Attachment | 8 hours |

2. | Head Attachment Pin | 8 hours |

3. | Boom Linkage Pin | 8 hours |

4. | Tilt Cylinder Pivot | 8 hours |

5. | Spindle Assembly | 8 hours |

6. | Boom Sleeve | 8 hours |

NOTE: Check oil level and as needed.

EK II 03/09 | Maintenance Section |

©2009 Alamo Group Inc.