Reinstallation of Shipping Materials

To prevent damage while moving the washer, the shipping materials MUST be reinstalled.

∙Disconnect washer from electrical supply.

∙While supporting the front access panel, remove two screws from the bottom edge of the panel.

∙Gently lower the panel to remove it from the washer.

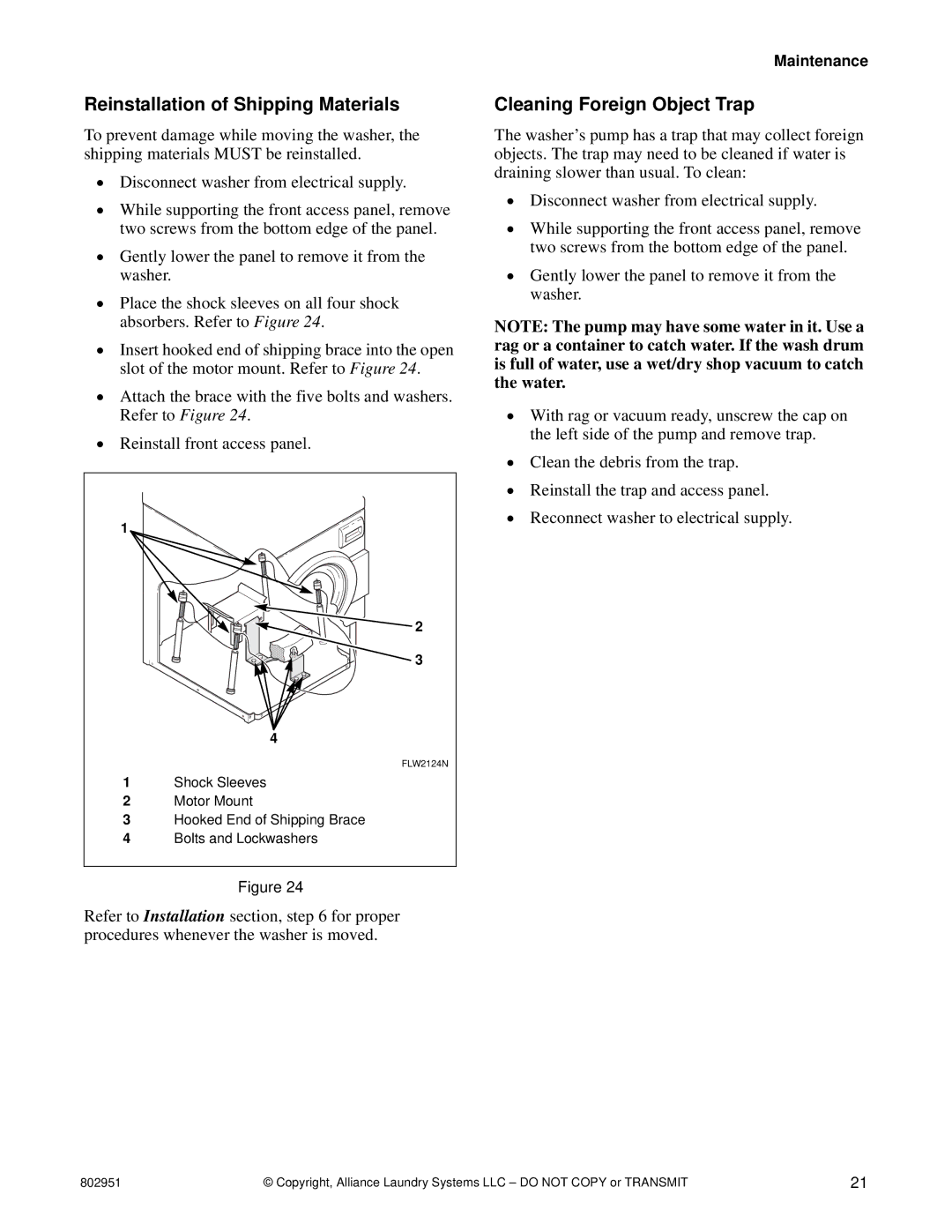

∙Place the shock sleeves on all four shock absorbers. Refer to Figure 24.

∙Insert hooked end of shipping brace into the open slot of the motor mount. Refer to Figure 24.

∙Attach the brace with the five bolts and washers. Refer to Figure 24.

∙Reinstall front access panel.

1 |

|

|

|

| 2 |

|

| 3 |

| 4 | FLW2124N |

|

| |

|

| FLW2124N |

1 | Shock Sleeves |

|

2 | Motor Mount |

|

3 | Hooked End of Shipping Brace | |

4 | Bolts and Lockwashers |

|

Figure 24

Refer to Installation section, step 6 for proper procedures whenever the washer is moved.

Maintenance

Cleaning Foreign Object Trap

The washer’s pump has a trap that may collect foreign objects. The trap may need to be cleaned if water is draining slower than usual. To clean:

∙Disconnect washer from electrical supply.

∙While supporting the front access panel, remove two screws from the bottom edge of the panel.

∙Gently lower the panel to remove it from the washer.

NOTE: The pump may have some water in it. Use a rag or a container to catch water. If the wash drum is full of water, use a wet/dry shop vacuum to catch the water.

∙With rag or vacuum ready, unscrew the cap on the left side of the pump and remove trap.

∙Clean the debris from the trap.

∙Reinstall the trap and access panel.

∙Reconnect washer to electrical supply.

802951 | © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT | 21 |