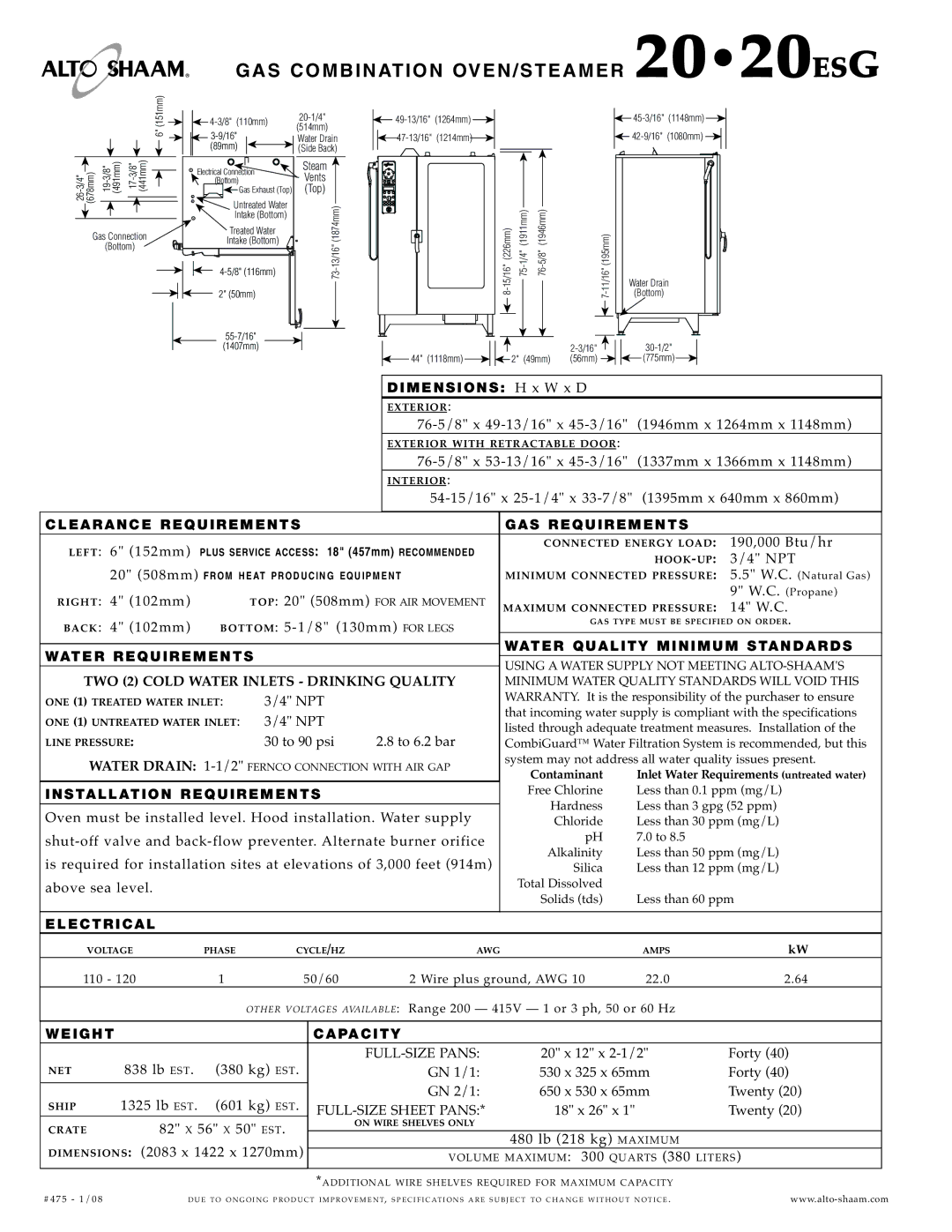

20.20ESG specifications

The Alto-Shaam 20.20ESG is an innovative solution for commercial kitchens, designed specifically for operators seeking efficiency, versatility, and quality in food preparation. This equipment offers a range of features and technologies that position it at the forefront of modern cooking systems.One of the standout features of the Alto-Shaam 20.20ESG is its Advanced SmartHold Technology. This unique system allows operators to precisely manage food temperature and hold times without compromising the quality of the dish. The technology supports a range of cooking methods, ensuring that food retains its freshness, flavor, and texture, making it ideal for high-volume establishments.

The unit is equipped with a sleek, stainless-steel exterior that not only enhances its aesthetic appeal but also ensures durability in bustling kitchen environments. Internally, the Alto-Shaam 20.20ESG boasts a spacious cooking chamber that can accommodate a variety of foods, from proteins to vegetables. The flexible cooking options, including steam, convection, and combination modes, make it suitable for diverse menu items.

Another significant characteristic of the 20.20ESG is its user-friendly digital controls. Operators can easily set and monitor cooking parameters through an intuitive touchscreen interface, providing a seamless cooking experience. The programmable features enable users to create and save popular menus, streamlining operations and reducing the potential for errors during service.

Efficiency is paramount in any commercial kitchen, and the Alto-Shaam 20.20ESG excels in this area with its energy-efficient design. The unit is engineered to consume less energy while maintaining optimal cooking performance, which not only lowers operational costs but also aligns with sustainability goals.

Moreover, the unit’s design promotes easy cleaning and maintenance, ensuring that kitchen staff can keep it in top working condition without consuming too much time or effort. The removable water reservoir and grease management system contribute to a cleaner and safer kitchen environment.

In summary, the Alto-Shaam 20.20ESG is a state-of-the-art cooking solution that combines advanced technology, versatility, and efficiency, making it an essential tool for any commercial kitchen aiming to elevate its culinary offerings while optimizing operations. With its myriad features and user-friendly design, it is well-suited to meet the demands of today’s foodservice industry.