HFT2SYS-300, HFT2SYS-500, HFT2-500, HFT2SYS-400, HFT2-300 specifications

Alto-Shaam is renowned for its innovative cooking technologies, and the HFT series represents a significant advancement in holding and cooking equipment. The HFT2-400, HFT2-300, HFT2SYS-400, HFT2-500, and HFT2SYS-500 models are exceptional pieces of equipment designed to meet the high demands of modern commercial kitchens.The HFT2-400 stands as a versatile solution for high-volume operations. It is equipped with patented Halo Heat® technology, which ensures even heat distribution while maintaining food quality. The unit holds a variety of food items, including meats, vegetables, and baked goods, keeping them at optimal serving temperatures for extended periods.

Similarly, the HFT2-300 model is ideal for smaller kitchens or operations needing a compact yet efficient holding solution. It features the same Halo Heat® technology, which eliminates the need for water pans, allowing for easy maintenance and operation. Its energy-efficient design not only conserves power but also reduces operating costs, making it an economical choice for many establishments.

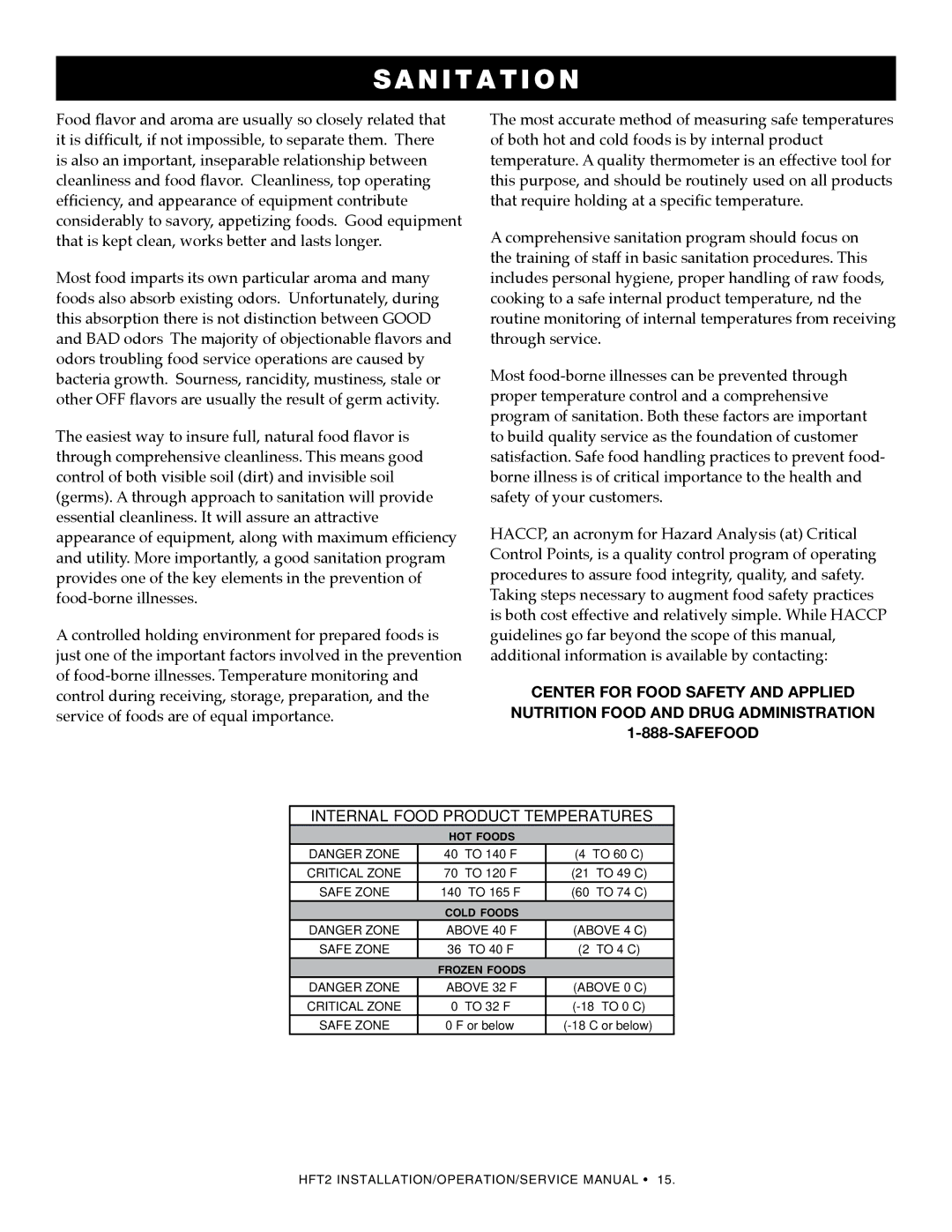

The HFT2SYS-400 and HFT2SYS-500 models introduce a unique system configuration that allows for dual-zone temperature control. This feature ensures that different types of food can be held in their ideal temperature range simultaneously, enhancing menu variety without sacrificing quality. With user-friendly digital controls, operators can easily adjust settings and monitor holding temperatures in real time.

The HFT2-500 model offers a larger capacity, catering to larger operations or catering services. Its robust construction and advanced thermal performance make it a reliable option for maintaining food integrity during peak service hours. The unit also integrates seamlessly with other kitchen equipment, providing a cohesive workflow in busy kitchens.

All models in the HFT series are designed with ease of use in mind. The clear LCD displays provide operators with immediate feedback on settings and temperatures, while easy-to-clean interiors minimize downtime and simplify maintenance.

In conclusion, Alto-Shaam's HFT2-400, HFT2-300, HFT2SYS-400, HFT2-500, and HFT2SYS-500 models showcase cutting-edge technology that enhances food service efficiency. With their reliable performance, innovative features, and user-friendly design, these units are the ideal choice for any commercial kitchen looking to maintain food quality and streamline operations.