2034, 2004 specifications

The American Standard 2034 and 2004 models represent a significant leap in plumbing fixture technology, emphasizing efficiency, durability, and user comfort. Both models are part of a broader initiative by American Standard to create high-performing, water-efficient solutions for residential and commercial spaces.One of the main features of the American Standard 2034 is its WaterSense certification, which ensures that the fixture consumes less water without sacrificing performance. This model typically uses approximately 1.28 gallons per flush, significantly reducing water usage compared to traditional toilets. The dual-flush technology present in the 2004 model provides users with the option of a low-volume flush for liquid waste and a higher volume flush for solid waste. This flexibility not only conserves water but also promotes sustainable bathroom practices.

Both models boast a sleek and modern design, which enhances the aesthetic appeal of any bathroom. The elongated bowl in these toilets provides additional comfort, making them more user-friendly, especially for adults. The ergonomic height is designed to accommodate users of all ages, which is particularly beneficial in homes with older adults or individuals with mobility concerns.

In terms of cleaning and maintenance, the American Standard 2034 and 2004 are engineered with a smooth surface that reduces the accumulation of dirt and stains. The industry-leading EverClean surface is also a notable feature, as it contains an antimicrobial finish that inhibits the growth of mold, mildew, and bacteria, ensuring a cleaner and more hygienic bathroom environment.

Technologically, these models are equipped with a powerful flushing system that maximizes performance while minimizing noise. The flush valve and trapway are designed for optimal water flow, preventing clogs and ensuring a reliable flushing experience.

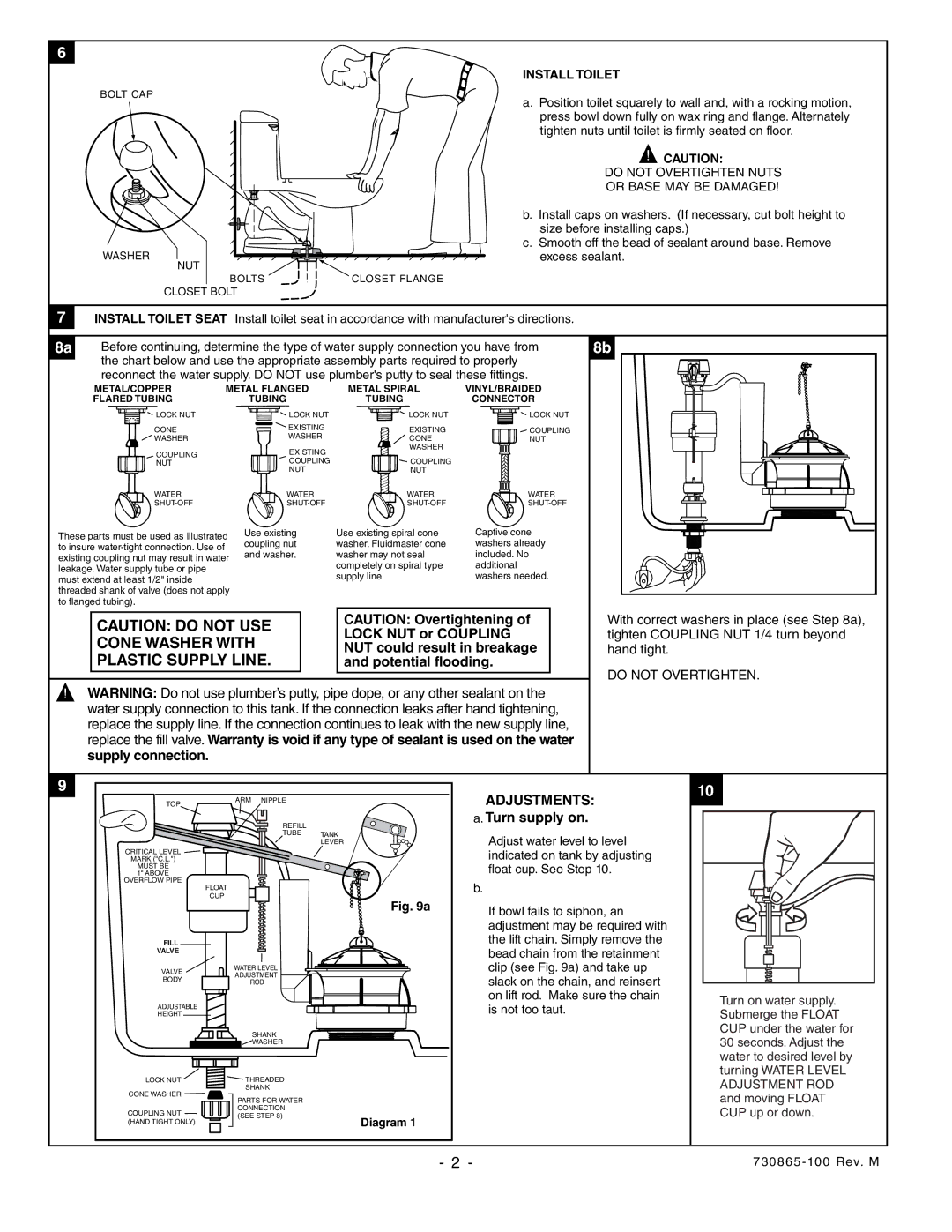

Another characteristic that stands out in both the 2034 and 2004 models is their ease of installation. These toilets come with a straightforward installation guide and are compatible with standard plumbing fixtures, making it easier for homeowners and contractors alike to integrate them into existing bathroom setups.

In summary, the American Standard 2034 and 2004 toilets are a testament to advanced design and technology in plumbing fixtures. Their focus on water efficiency, comfort, ease of use, and low maintenance requirements makes them an excellent choice for anyone looking to upgrade their bathroom facilities while contributing to environmental conservation efforts.