3 FT.

Minimum

Support Strap

Maintain

Clearance*

Vent

Connector

Slope Up

1/4 Inch

Per Foot

Minimum

2 FT. Minimum Above

Any Object Within

10 FT. Horizontally

Type B Double

Wall Vent Pipe

**Maintain Specified Clearance

WATER SYSTEM PIPING

Piping Installation

Piping, fittings, and valves should be installed according to the installation drawing (Figure 13). If the indoor installation area is subject to freezing temperatures, the water piping must be protected by insulation.

The water supply pressure should not exceed 80 psi. If this occurs, a pressure reducing valve with a bypass may need to be installed in the cold water inlet line. This should be placed on the supply to the entire house in order to maintain equal hot and cold water pressures.

IMPORTANT: Heat cannot be applied to the water fittings on the heater as they may contain nonmetallic parts. If solder connections are used, solder the pipe to the adapter before attaching the adapter to the hot and cold water fittings.

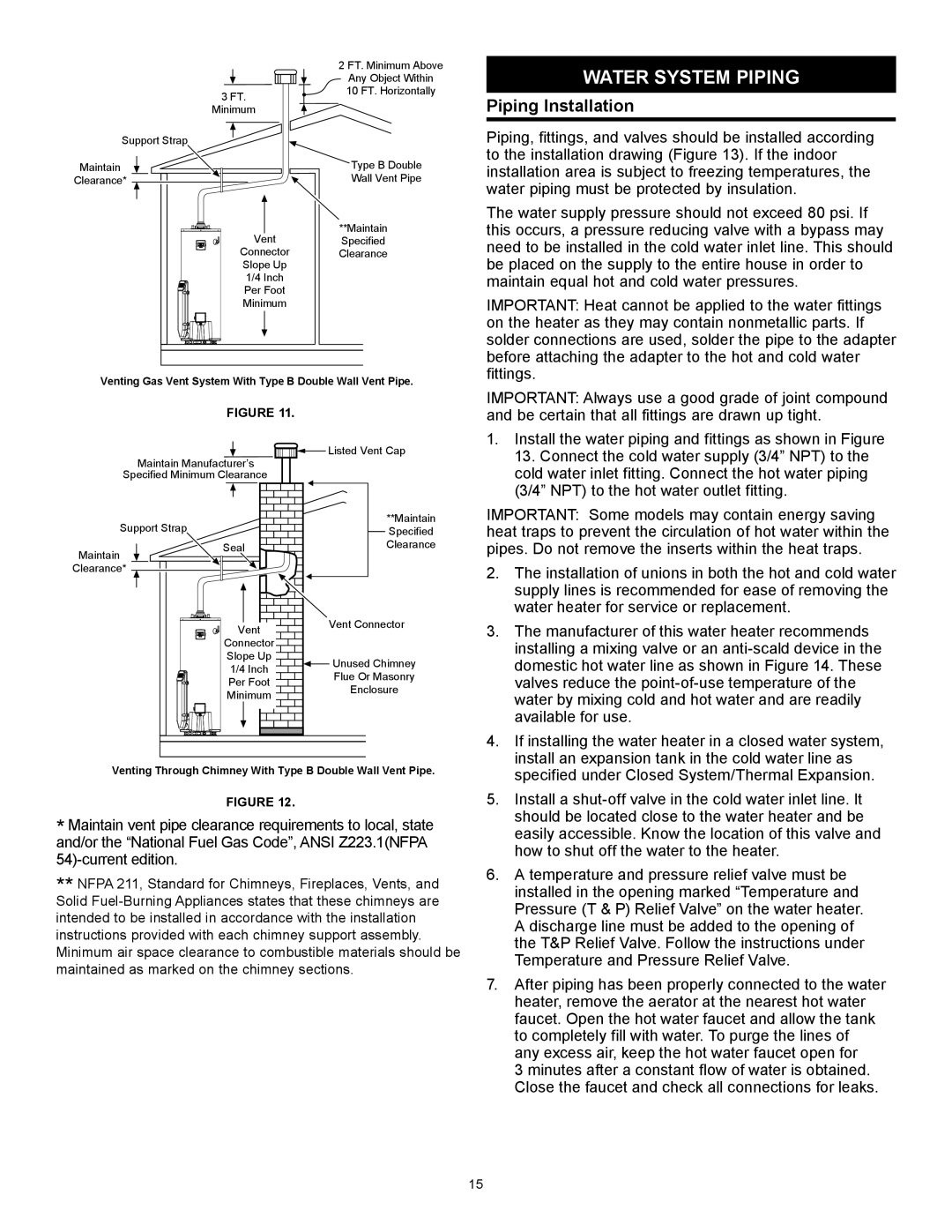

Venting Gas Vent System With Type B Double Wall Vent Pipe.

|

|

|

|

|

|

|

|

|

|

|

| FIGURE 11. |

|

|

|

|

|

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Listed Vent Cap | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

| Maintain Manufacturer’s |

|

|

|

|

|

|

|

|

| |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||

| Specified Minimum Clearance |

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| **Maintain |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| Support Strap |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Specified | ||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||

Maintain |

|

|

|

|

|

|

|

|

| Seal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Clearance | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

Clearance* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| |||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Vent Connector | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

| Vent |

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| Connector |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

| Slope Up |

|

|

|

|

|

|

|

|

| Unused Chimney | ||||||||||

|

|

|

|

|

|

|

|

|

|

|

| 1/4 Inch |

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Flue Or Masonry | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

| Per Foot |

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

| Minimum |

|

|

|

|

|

|

|

|

|

|

| Enclosure | ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Venting Through Chimney With Type B Double Wall Vent Pipe.

FIGURE 12.

*Maintain vent pipe clearance requirements to local, state and/or the “National Fuel Gas Code”, ANSI Z223.1(NFPA

**NFPA 211, Standard for Chimneys, Fireplaces, Vents, and Solid

IMPORTANT: Always use a good grade of joint compound and be certain that all fittings are drawn up tight.

1.Install the water piping and fittings as shown in Figure 13. Connect the cold water supply (3/4” NPT) to the cold water inlet fitting. Connect the hot water piping (3/4” NPT) to the hot water outlet fitting.

IMPORTANT: Some models may contain energy saving heat traps to prevent the circulation of hot water within the pipes. Do not remove the inserts within the heat traps.

2.The installation of unions in both the hot and cold water supply lines is recommended for ease of removing the water heater for service or replacement.

3.The manufacturer of this water heater recommends installing a mixing valve or an

4.If installing the water heater in a closed water system, install an expansion tank in the cold water line as specified under Closed System/Thermal Expansion.

5.Install a

6.A temperature and pressure relief valve must be installed in the opening marked “Temperature and Pressure (T & P) Relief Valve” on the water heater. A discharge line must be added to the opening of the T&P Relief Valve. Follow the instructions under Temperature and Pressure Relief Valve.

7.After piping has been properly connected to the water heater, remove the aerator at the nearest hot water faucet. Open the hot water faucet and allow the tank to completely fill with water. To purge the lines of any excess air, keep the hot water faucet open for

3 minutes after a constant flow of water is obtained. Close the faucet and check all connections for leaks.

15