Washing And Drying System specifications

The AMF Washing and Drying System represents a significant advancement in laundry technology, designed to meet the rigorous demands of commercial and industrial laundries. With its state-of-the-art features and innovative technologies, this system combines efficiency, performance, and sustainability, making it an ideal choice for businesses looking to enhance their laundry operations.One of the main features of the AMF system is its energy-efficient design. The system is equipped with advanced heat recovery technologies that capture and reuse heat from the drying process, significantly reducing energy consumption. This not only lowers operating costs but also minimizes the environmental impact of laundry operations, aligning with global sustainability initiatives.

The AMF Washing and Drying System also boasts advanced control systems that allow for precise monitoring and management of each cycle. This ensures optimal wash and dry performance by adjusting the parameters based on the type of fabric and load size. The intuitive user interface provides operators with real-time data, facilitating quick adjustments and maximizing throughput.

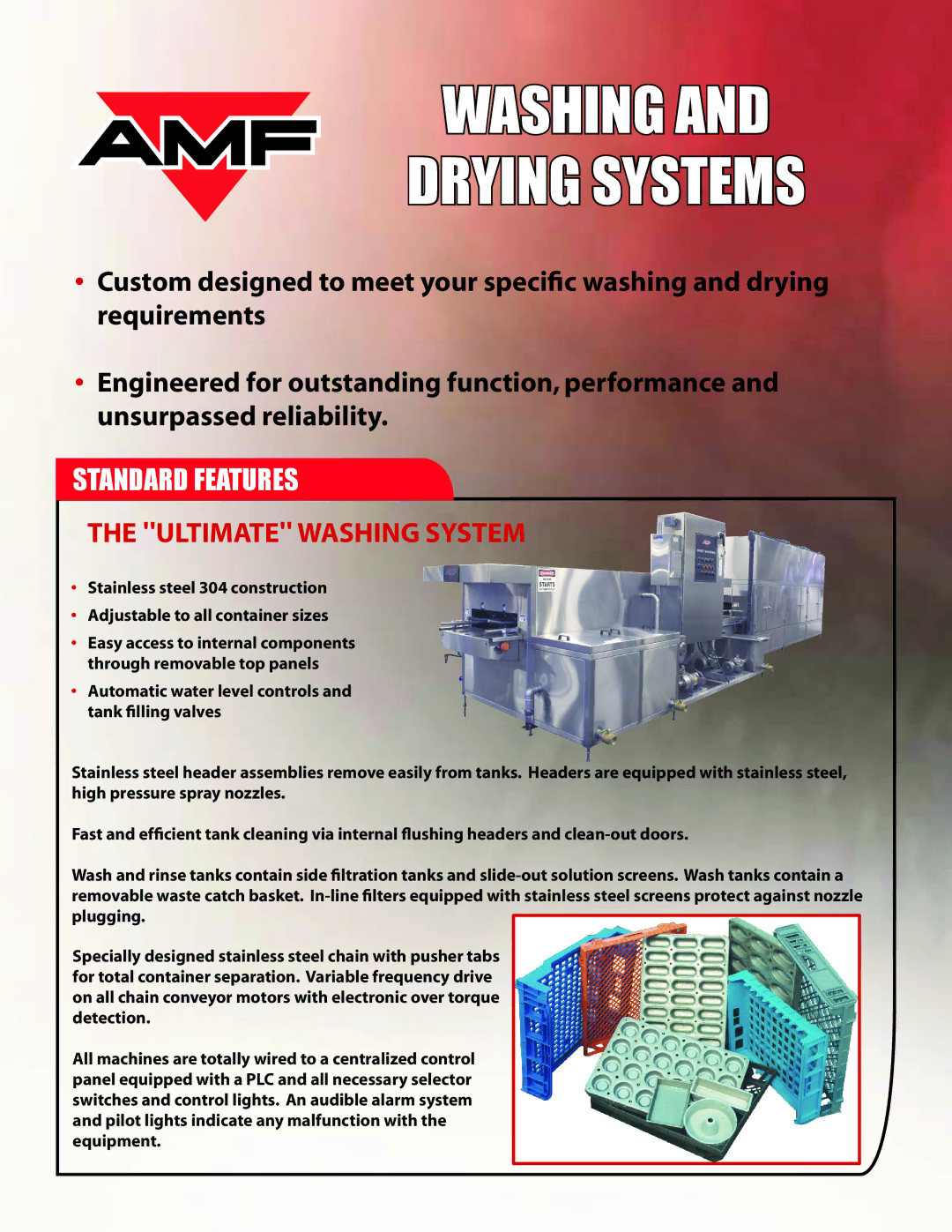

Durability and reliability are key characteristics of the AMF system. Built with high-quality materials and designed for heavy-duty use, it can withstand the rigors of commercial laundry environments. The robust construction reduces downtime, increasing productivity and allowing businesses to meet tight turnaround times.

The system incorporates intelligent technology such as adaptive washing algorithms that customize the wash cycle based on soil levels and load type. This capability not only improves cleaning performance but also extends the life of garments by preventing damage from excessive agitation or incorrect cycle settings.

In addition, the AMF system includes features such as automatic chemical dispensing, which ensures consistent dosing and optimal cleaning results. This automation minimizes human error and reduces chemical waste, further enhancing operational efficiency.

Another noteworthy aspect is the system's versatility. It can accommodate a wide range of fabrics, from delicate materials to heavy-duty linens, making it suitable for various applications in hospitality, healthcare, and industrial sectors.

In conclusion, the AMF Washing and Drying System stands out in the marketplace due to its combination of energy efficiency, advanced technology, durability, and versatility. As businesses increasingly prioritize sustainability and efficiency in their operations, this system offers a comprehensive solution to meet those needs while delivering outstanding laundry performance.