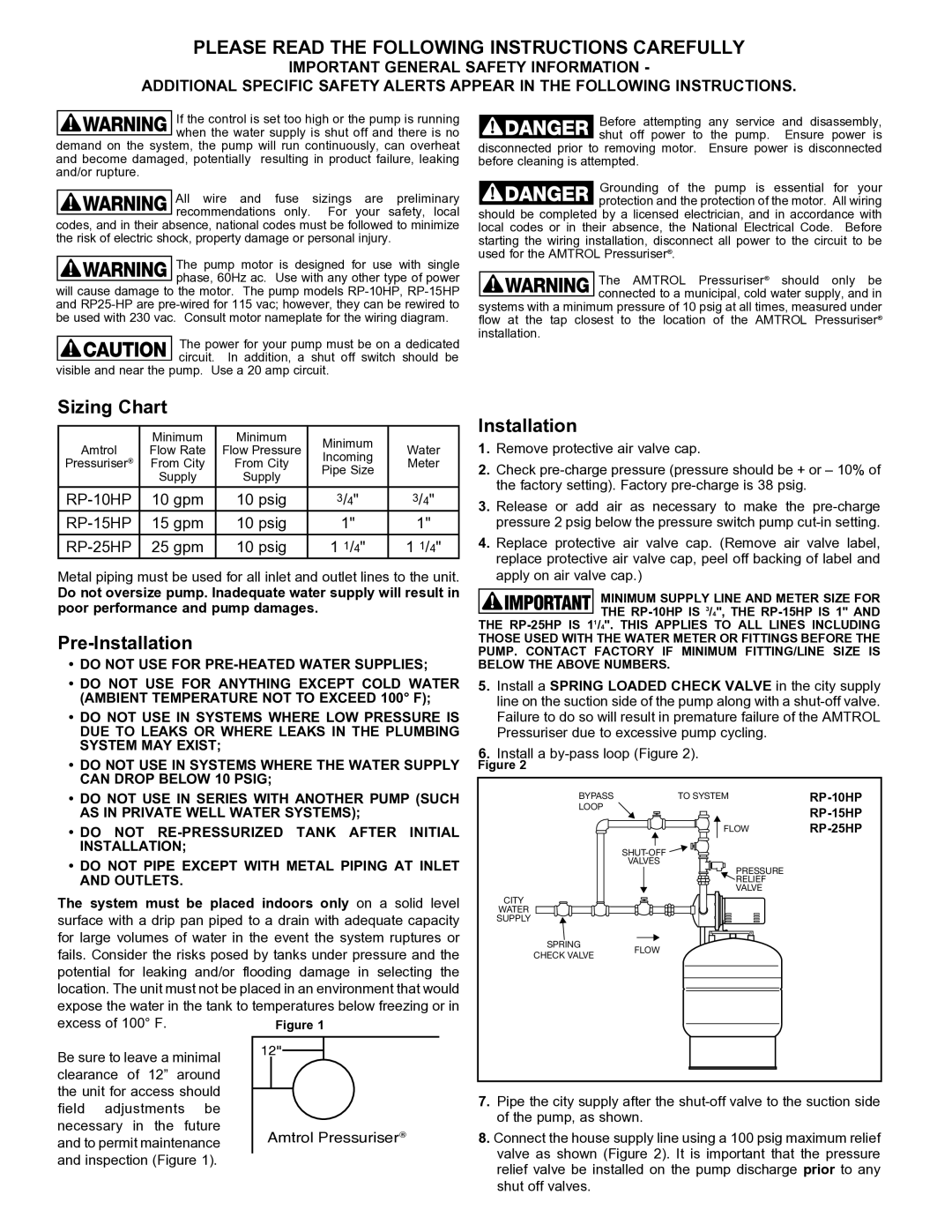

RP-15HP, RP-10HP, RP-25HP specifications

Amtrol, a well-regarded name in the industry of pressure tanks and water systems, offers a range of products designed for durability, efficiency, and optimal performance. Among their lineup, the RP series, which includes the RP-15HP, RP-25HP, and RP-10HP models, stands out for a variety of reasons.The RP-15HP, RP-25HP, and RP-10HP are designed primarily for residential and light commercial applications, making them versatile units suitable for various settings. One of their key features is their construction; these tanks are manufactured using high-quality steel, which ensures strength and longevity. The tanks are also coated with a corrosion-resistant finish, providing an added layer of protection against wear and tear from environmental factors.

Another defining characteristic of the Amtrol RP series is their internal liner, which is designed to keep water clean and fresh. This feature is particularly valuable in maintaining health standards in potable water applications. The tanks are also lightweight and easy to install, which simplifies the process for both professionals and DIY enthusiasts.

In terms of technology, the RP series incorporates advanced manufacturing processes. The design features a unique diaphragm system, which helps to create a barrier between the water and air, reducing the risk of contamination. This advanced technology not only extends the life of the tank but also improves the efficiency of water delivery systems.

The RP-15HP, RP-25HP, and RP-10HP models come with different capacities, catering to the varying demands of users. The RP-10HP has a smaller capacity, making it ideal for single-family homes, while the RP-15HP and RP-25HP models are suited for larger households or light commercial applications where more water storage is required.

Energy efficiency is another highlight of these models. The diaphragm technology reduces the need for the pump to cycle frequently, thereby saving energy and lowering operational costs. This efficiency not only benefits the environment but also aligns with the growing demand for sustainable solutions in water management systems.

In summary, the Amtrol RP-15HP, RP-25HP, and RP-10HP tanks offer a blend of durability, innovative technology, and energy efficiency, making them a smart choice for anyone looking to invest in a reliable water storage solution. With their impressive features and solid construction, these tanks are built to meet the demands of modern water systems while ensuring user satisfaction and sustainability.