ELECTROCUTION HAZARD. DISCONNECT

ALL ELECTRICAL POWER BEFORE SERVICING. THE GUARDIAN CP™ MUST BE ELECTRICALLY GROUNDED.

The Guardian CP™ will operate on 115 vac & 230 vac systems. 9. Disconnect power and verify with a volt meter.

10.Determine the pump electrical requirements. If unknown, contact the pump manufacturer.

11.Select the appropriate wire gauge per local codes and the pump manufacturer’s recommendation. All pumps are 1/2 horsepower and are rated at 10.6 amps for 115 volts and 5.3 amps for 230 volts.

12.Loosen the captive fastener on the top of the controller and remove the plastic cover, exposing the wire leads. (When reassembling cover, do not over-tighten fastener.)

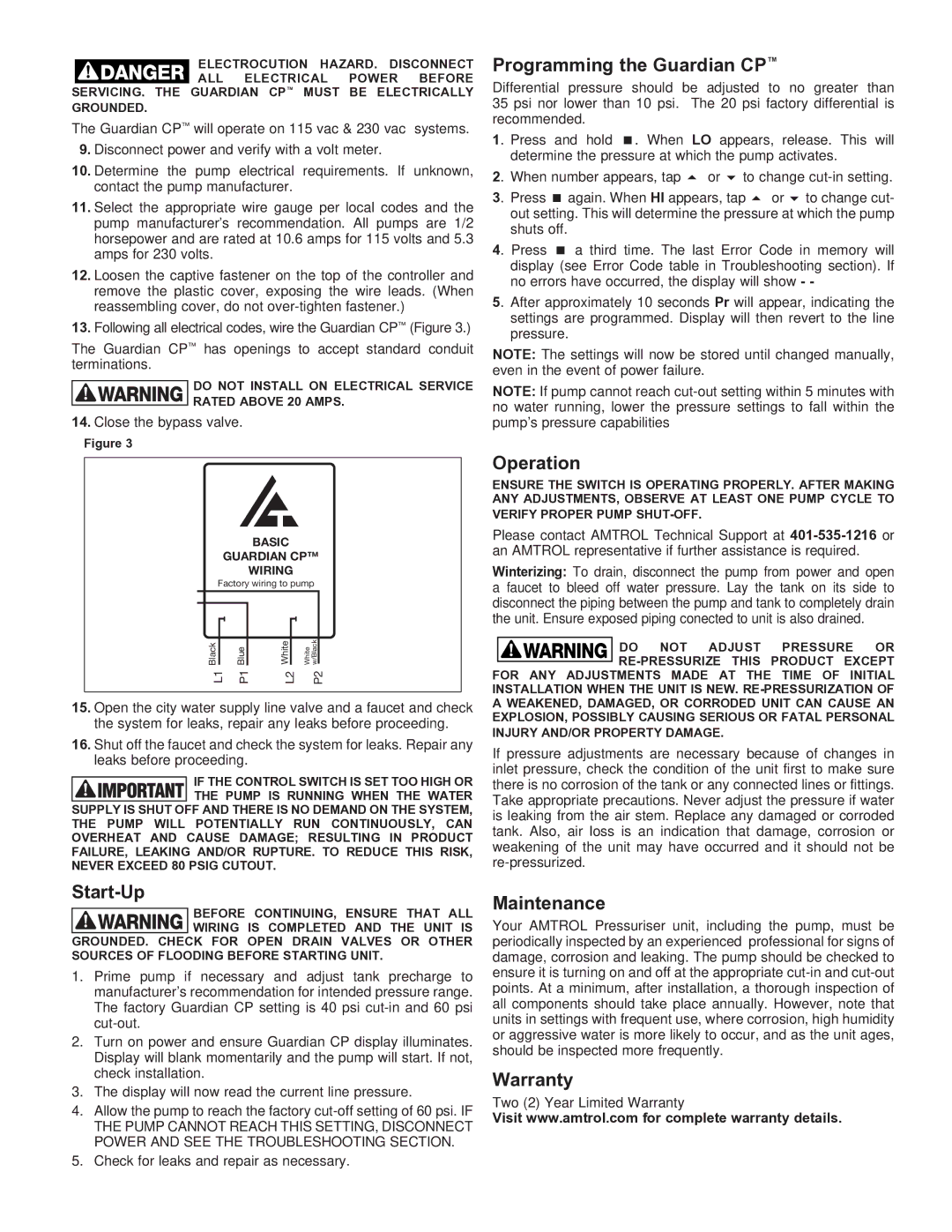

13.Following all electrical codes, wire the Guardian CP™ (Figure 3.)

The Guardian CP™ has openings to accept standard conduit terminations.

DO NOT INSTALL ON ELECTRICAL SERVICE  RATED ABOVE 20 AMPS.

RATED ABOVE 20 AMPS.

14.Close the bypass valve.

Figure 3

BASIC

GUARDIAN CP™

WIRING

Factory wiring to pump

| | | | White | | | White w/Black | |

Black | | | Blue | | | |

| | | | |

L1 | | P1 | L2 | P2 |

15.Open the city water supply line valve and a faucet and check the system for leaks, repair any leaks before proceeding.

16.Shut off the faucet and check the system for leaks. Repair any leaks before proceeding.

IF THE CONTROL SWITCH IS SET TOO HIGH OR

THE PUMP IS RUNNING WHEN THE WATER SUPPLY IS SHUT OFF AND THERE IS NO DEMAND ON THE SYSTEM, THE PUMP WILL POTENTIALLY RUN CONTINUOUSLY, CAN OVERHEAT AND CAUSE DAMAGE; RESULTING IN PRODUCT FAILURE, LEAKING AND/OR RUPTURE. TO REDUCE THIS RISK, NEVER EXCEED 80 PSIG CUTOUT.

Start-Up

BEFORE CONTINUING, ENSURE THAT ALL

WIRING IS COMPLETED AND THE UNIT IS GROUNDED. CHECK FOR OPEN DRAIN VALVES OR OTHER SOURCES OF FLOODING BEFORE STARTING UNIT.

1.Prime pump if necessary and adjust tank precharge to manufacturer’s recommendation for intended pressure range. The factory Guardian CP setting is 40 psi cut-in and 60 psi cut-out.

2.Turn on power and ensure Guardian CP display illuminates. Display will blank momentarily and the pump will start. If not, check installation.

3.The display will now read the current line pressure.

4.Allow the pump to reach the factory cut-off setting of 60 psi. IF THE PUMP CANNOT REACH THIS SETTING, DISCONNECT POWER AND SEE THE TROUBLESHOOTING SECTION.

5.Check for leaks and repair as necessary.

Programming the Guardian CP™

Differential pressure should be adjusted to no greater than 35 psi nor lower than 10 psi. The 20 psi factory differential is recommended.

1. Press and hold . When LO appears, release. This will determine the pressure at which the pump activates.

2. When number appears, tap or to change cut-in setting.

3. Press again. When HI appears, tap or to change cut- out setting. This will determine the pressure at which the pump shuts off.

4. Press a third time. The last Error Code in memory will display (see Error Code table in Troubleshooting section). If no errors have occurred, the display will show - -

5. After approximately 10 seconds Pr will appear, indicating the settings are programmed. Display will then revert to the line pressure.

NOTE: The settings will now be stored until changed manually, even in the event of power failure.

NOTE: If pump cannot reach cut-out setting within 5 minutes with no water running, lower the pressure settings to fall within the pump’s pressure capabilities

Operation

ENSURE THE SWITCH IS OPERATING PROPERLY. AFTER MAKING ANY ADJUSTMENTS, OBSERVE AT LEAST ONE PUMP CYCLE TO VERIFY PROPER PUMP SHUT-OFF.

Please contact AMTROL Technical Support at 401-535-1216or an AMTROL representative if further assistance is required.

Winterizing: To drain, disconnect the pump from power and open a faucet to bleed off water pressure. Lay the tank on its side to disconnect the piping between the pump and tank to completely drain the unit. Ensure exposed piping conected to unit is also drained.

DO NOT ADJUST PRESSURE OR

RE-PRESSURIZE THIS PRODUCT EXCEPT FOR ANY ADJUSTMENTS MADE AT THE TIME OF INITIAL INSTALLATION WHEN THE UNIT IS NEW. RE-PRESSURIZATION OF A WEAKENED, DAMAGED, OR CORRODED UNIT CAN CAUSE AN EXPLOSION, POSSIBLY CAUSING SERIOUS OR FATAL PERSONAL INJURY AND/OR PROPERTY DAMAGE.

RE-PRESSURIZE THIS PRODUCT EXCEPT FOR ANY ADJUSTMENTS MADE AT THE TIME OF INITIAL INSTALLATION WHEN THE UNIT IS NEW. RE-PRESSURIZATION OF A WEAKENED, DAMAGED, OR CORRODED UNIT CAN CAUSE AN EXPLOSION, POSSIBLY CAUSING SERIOUS OR FATAL PERSONAL INJURY AND/OR PROPERTY DAMAGE.

If pressure adjustments are necessary because of changes in inlet pressure, check the condition of the unit first to make sure there is no corrosion of the tank or any connected lines or fittings. Take appropriate precautions. Never adjust the pressure if water is leaking from the air stem. Replace any damaged or corroded tank. Also, air loss is an indication that damage, corrosion or weakening of the unit may have occurred and it should not be re-pressurized.

Maintenance

Your AMTROL Pressuriser unit, including the pump, must be periodically inspected by an experienced professional for signs of damage, corrosion and leaking. The pump should be checked to ensure it is turning on and off at the appropriate cut-in and cut-out points. At a minimum, after installation, a thorough inspection of all components should take place annually. However, note that units in settings with frequent use, where corrosion, high humidity or aggressive water is more likely to occur, and as the unit ages, should be inspected more frequently.

Warranty

Two (2) Year Limited Warranty

Visit www.amtrol.com for complete warranty details.