A-325 Tensioning

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

During the installation process, there are several references to the

NOTE: Tensioned bolts are for final connections only and should not be loosened for reuse.

Lubricate the bolt threads with the provided stick wax to reduce friction.

Insert the bolt, and add a flat

Add the nut, and finger tighten.

After the connections are complete, tighten the bolts until the surfaces are joined and the nuts are snug (for example, full effort of a person using an ordinary spud wrench). Do not proceed with Steps 5 and 6, unless the connection is final and is not intended to be loosened again.

Note: If the bolts are loosened after Steps 5 and 6, discard and replace with new hard- ware.

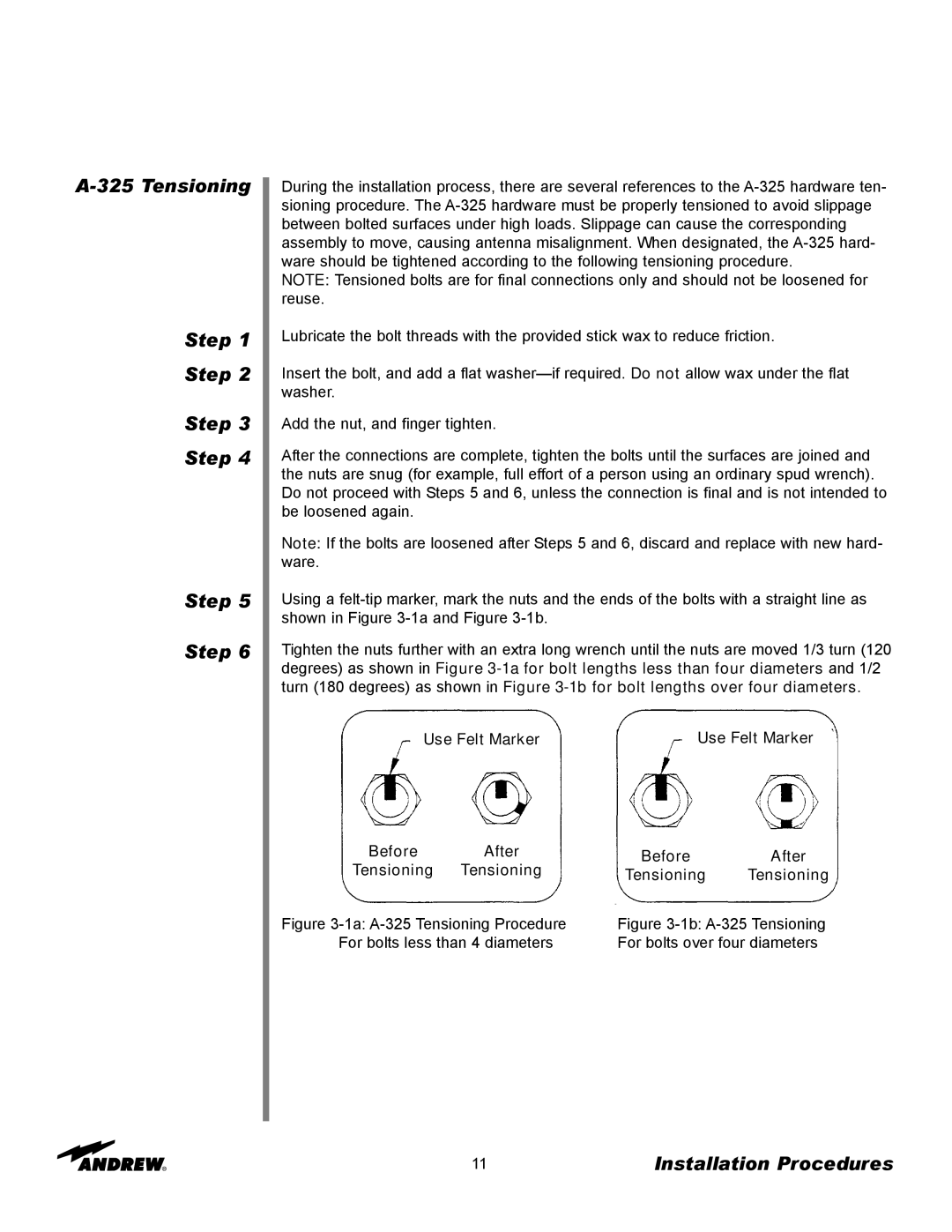

Using a

Tighten the nuts further with an extra long wrench until the nuts are moved 1/3 turn (120 degrees) as shown in Figure

Use Felt Marker

Before After

Tensioning Tensioning

Figure 3-1a: A-325 Tensioning Procedure For bolts less than 4 diameters

Use Felt Marker

Before After

Tensioning Tensioning

Figure 3-1b: A-325 Tensioning For bolts over four diameters

11 | Installation Procedures |