Using the Drilling Template

·Place the top edge of the drilling template so that it is flush with the top edge of the panel, making sure that it is positioned correctly and centered in the horizontal direction (use the dotted lines on the edges to line the template up). Mark the points on the panel for the four holes.

·Use an appropriately sized router to mill the holes for the two hinges, the rubber plug and the magnet.

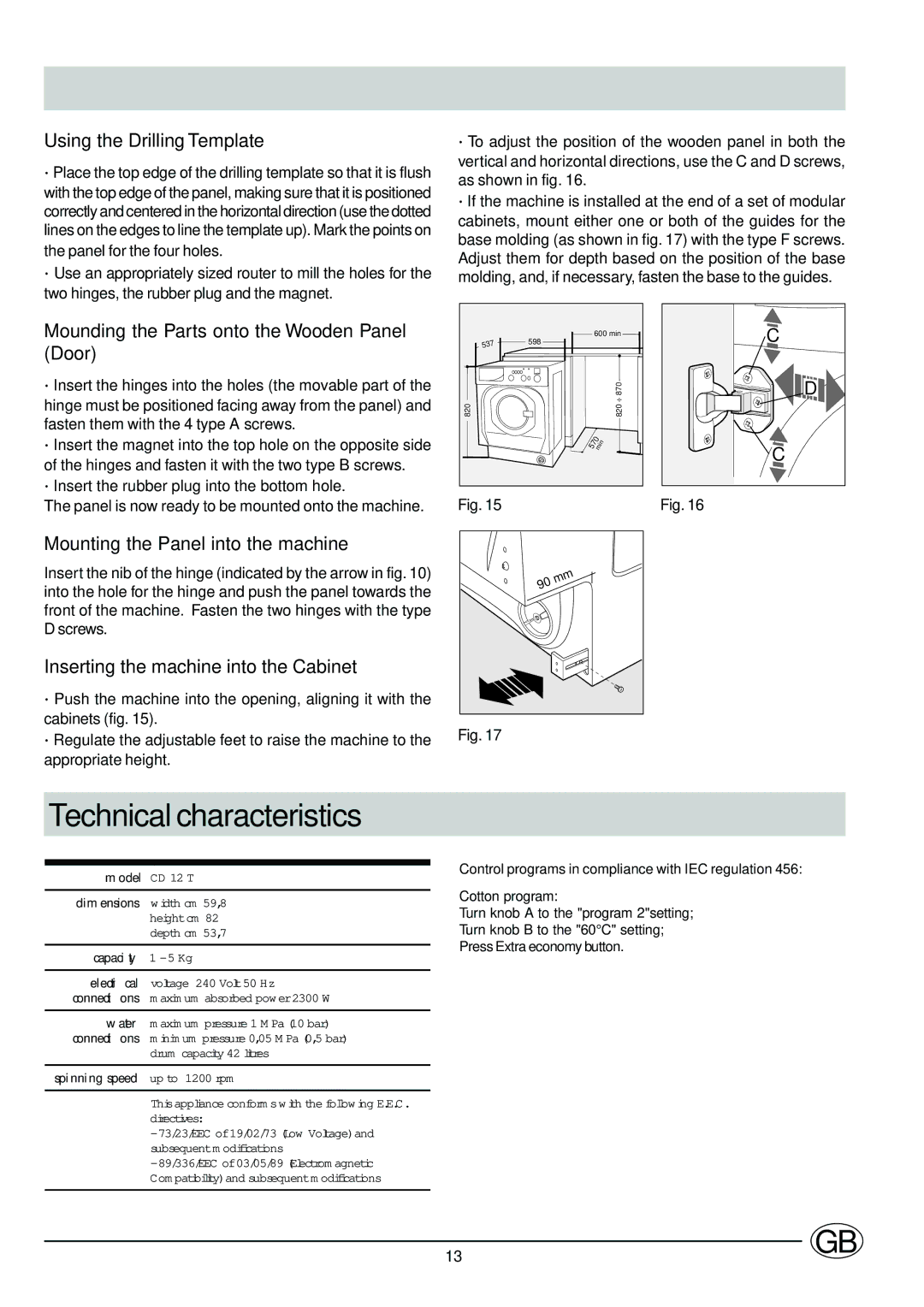

·To adjust the position of the wooden panel in both the vertical and horizontal directions, use the C and D screws, as shown in fig. 16.

·If the machine is installed at the end of a set of modular cabinets, mount either one or both of the guides for the base molding (as shown in fig. 17) with the type F screws. Adjust them for depth based on the position of the base molding, and, if necessary, fasten the base to the guides.

Mounding the Parts onto the Wooden Panel (Door)

·Insert the hinges into the holes (the movable part of the hinge must be positioned facing away from the panel) and fasten them with the 4 type A screws.

·Insert the magnet into the top hole on the opposite side of the hinges and fasten it with the two type B screws.

·Insert the rubber plug into the bottom hole.

The panel is now ready to be mounted onto the machine.

Mounting the Panel into the machine

Insert the nib of the hinge (indicated by the arrow in fig. 10) into the hole for the hinge and push the panel towards the front of the machine. Fasten the two hinges with the type

Dscrews.

Inserting the machine into the Cabinet

·Push the machine into the opening, aligning it with the cabinets (fig. 15).

·Regulate the adjustable feet to raise the machine to the appropriate height.

| 600 min | |

537 | 598 |

|

|

| |

820 |

| 870÷ 820 |

| 570 | min |

Fig. 15

90 | mm |

|

Fig. 17

C |

D |

C |

Fig. 16

Technical characteristics

m odel CD 12 T

dim ensions width cm 59,8 heightcm 82 depth cm 53,7

capacity 1 -5 Kg

electrical voltage 240 Volt50 Hz connections m axim um absorbed power2300 W

w ater m axim um pressure 1 M Pa (10 bar) connections m inim um pressure 0,05 M Pa (0,5 bar)

drum capacity 42 litres

spinning speed up to 1200 rpm

Thisappliance conform swith the following E.E.C. directives:

Com patibility)and subsequentm odifications

Control programs in compliance with IEC regulation 456:

Cotton program:

Turn knob A to the "program 2"setting;

Turn knob B to the "60°C" setting;

Press Extra economy button.

13

GB