Pipe | Connect the cold water inlet pipe to the inlet nipple (marked with a blue ring - #1, Fig. 4). | |

Connections | IMPORTANT: You must use dielectric fittings if inlet piping/fittings are copper or brass. | |

| Failure to provide dielectric insulation may result in premature tank or nipple failure and will | |

| void warranty. Dielectric nipples are recommended over unions and are available from a | |

| supply house or CEC. | |

Caution | To | reduce the risk of excessive pressures and temperatures in this water heater, install |

| temperature and pressure protective equipment required by local codes but not less than a | |

| combination temperature and pressure relief valve certified by a nationally recognized | |

| testing laboratory that maintains periodic inspection of production of listed equipment or | |

| materials, as meeting the requirements for Relief Valves and Automatic Gas | |

| Devices for Hot Water Supply Systems, ANSI Z21.22. This valve must be marked with a | |

| maximum set pressure not to exceed the marked maximum working pressure of the water | |

| heater. Install the valve into the opening provided and marked for this purpose in the water | |

| heater, and orient it or provide tubing so that any discharge from the valve will exit within 6 | |

| inches above, or at any distance below, the structural floor, and cannot contact any live | |

| electrical part. The discharge opening must not be blocked or reduced in size under any | |

| circumstances. | |

Closed | Periodic discharge of the temperature and pressure relief valve or failure of the element | |

system | gasket may be due to thermal expansion in a closed water supply system. The water utility | |

thermal | supply meter may contain a check valve, backflow preventer or water pressure reducing | |

expansion | valve which will create a closed water system. During the heating cycle of the water heater, | |

| the water expands causing pressure inside the water heater to increase. The temperature | |

| and pressure relief valve may discharge hot water under these conditions which results in a | |

| loss of energy and a | |

| To prevent this from happening, there are two recommendations: | |

| 1. | Install a |

|

| water supply line. The expansion tank must have a minimum capacity of 1.5 U.S. |

|

| gallons for every 50 gallons of stored water. |

| 2. | Install a 125 PSI pressure relief valve in the cold water supply line. Make sure the |

|

| discharge of this valve is directed to an open drain and protected from freezing. |

|

| Contact the local water supplier or plumbing inspector for information on how to |

|

| control this situation. Do not plug the temperature and pressure relief valve. |

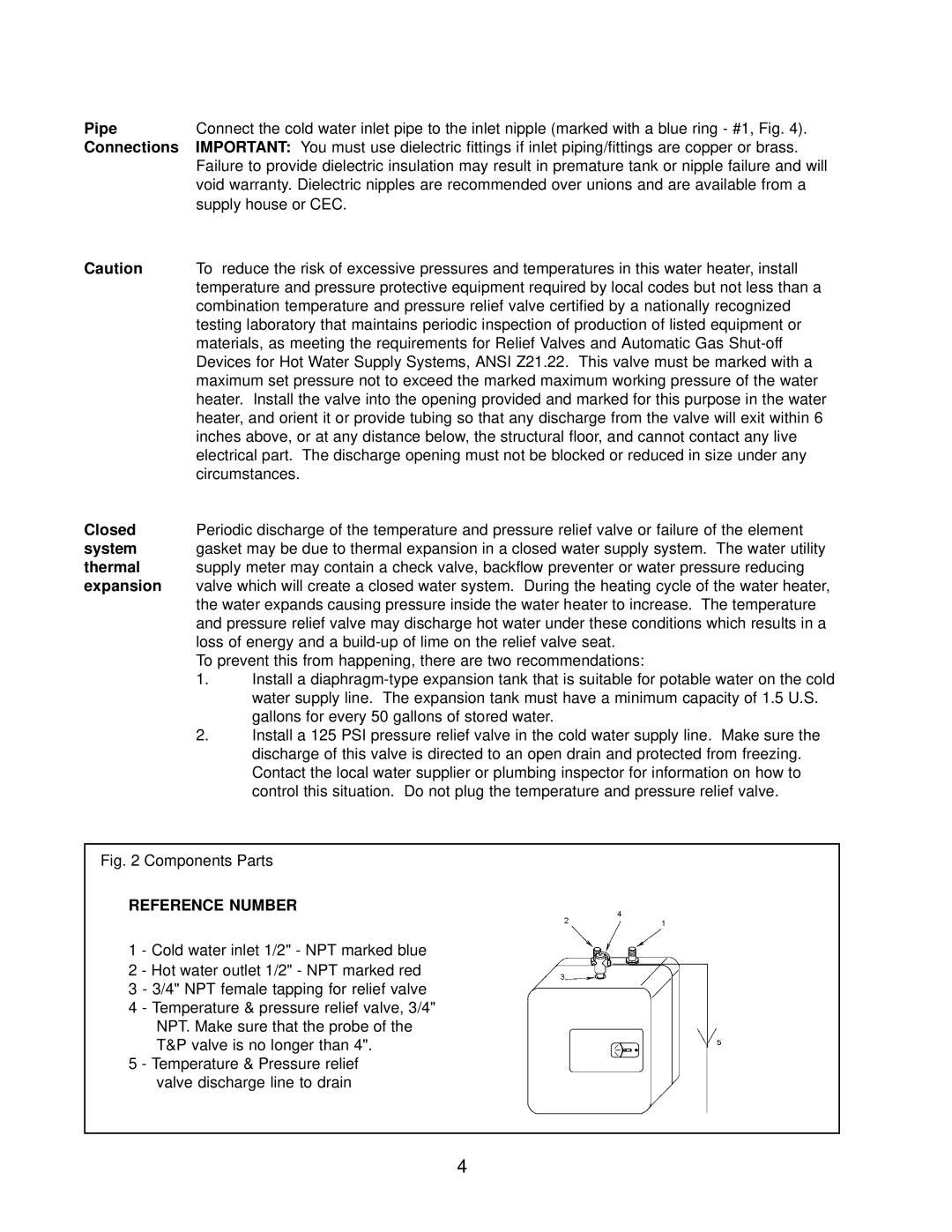

Fig. 2 Components Parts

REFERENCE NUMBER

1 - Cold water inlet 1/2" - NPT marked blue 2 - Hot water outlet 1/2" - NPT marked red

3 - 3/4" NPT female tapping for relief valve

4 - Temperature & pressure relief valve, 3/4" NPT. Make sure that the probe of the T&P valve is no longer than 4".

5 - Temperature & Pressure relief valve discharge line to drain

4