TRA-4150 specifications

The Ashly TRA-4150 is a robust, high-performance amplifier designed to meet the demanding requirements of modern audio installations. Known for its reliability and exceptional sound quality, the TRA-4150 is ideal for both commercial and residential applications, including venues such as auditoriums, houses of worship, and entertainment spaces.One of the defining features of the TRA-4150 is its power output. With a maximum output of 150 watts per channel at 4 ohms and 75 watts per channel at 8 ohms, this amplifier delivers enough power to drive a variety of speakers efficiently. It is equipped with a class AB topology, which ensures low distortion and high sound fidelity, making it suitable for critical listening environments.

The TRA-4150 boasts numerous advanced technologies designed to enhance performance and user experience. It incorporates a comprehensive protection system that includes thermal protection, short circuit protection, and DC fault protection, ensuring safe operation under various conditions. This reliability is crucial in professional settings where equipment failure is not an option.

Furthermore, the Ashly TRA-4150 features integrated signal processing capabilities, allowing users to optimize sound performance with ease. Its variable high-pass and low-pass filters enable tailored control over the audio signal, ensuring that sound output is clear and well-defined across frequencies.

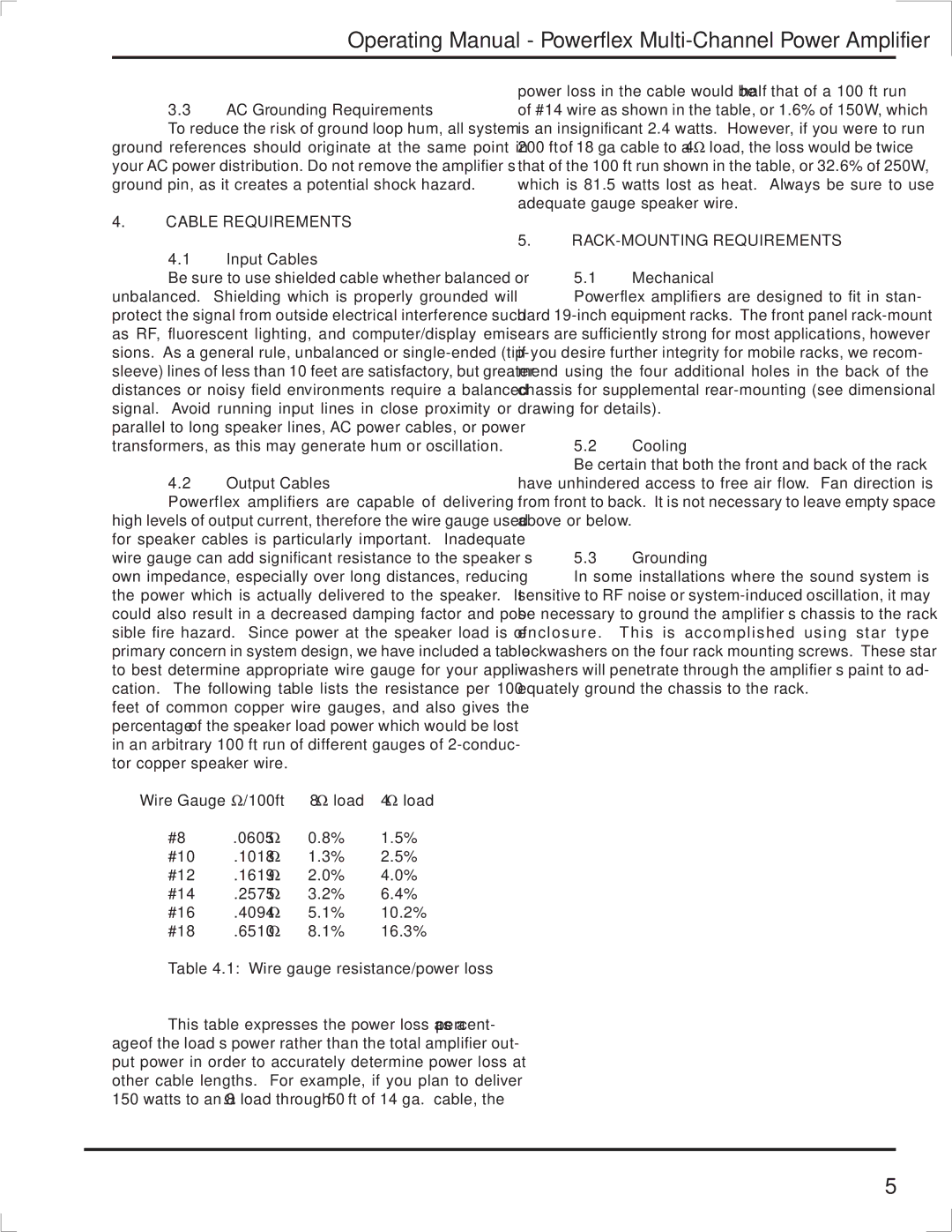

Connectivity is another strong point of the TRA-4150. The amplifier supports both balanced and unbalanced input options, ensuring compatibility with a variety of audio sources and equipment. Additionally, the unit has a convenient input gain control for each channel, allowing for precise adjustment of signal levels.

The design of the TRA-4150 is both sleek and functional. The unit has a compact form factor, making it easy to integrate into existing audio setups. Furthermore, the built-in fan cooling system ensures efficient heat dissipation, which is vital for maintaining performance during extended use.

Overall, the Ashly TRA-4150 amplifier stands out in the market due to its powerful output, advanced protection technologies, and user-friendly features. Whether in a live performance setting or a fixed installation, the TRA-4150 delivers reliability and exceptional audio quality, making it a preferred choice for audio professionals and enthusiasts alike.