PLACING THE TOOL IN SERVICE

ADJUSTMENTS | NOT allow the tool to react against the hoses, swivels, | |

| or inlets. | |

SETTING THE TORQUE | 3. After having turned the Pump on and presetting the | |

pressure for the correct torque, depress the remote | ||

After determining the desired torque, use the torque con- | ||

control button to advance the Piston Assembly. If the | ||

version chart on the Shroud or the torque conversion | ||

notch in the piston rod did not engage the Retract Pin in | ||

charts on pages 5 and 6 to determine the pressure that is | ||

the Ratchet Link when the Link was joined to the | ||

necessary to achieve that torque. | ||

Housing, it will engage the Pin automatically during the | ||

1. Connect the tool to the power supply and turn the | ||

first advance stroke. | ||

pump on. | ||

4. When the Link is connected to the Housing and the | ||

2. Depress the remote control button causing the | ||

wrench is started, the reaction surface of the wrench will | ||

pressure to be shown on the gauge. | ||

move against the contact point and the nut will begin to | ||

3. Adjust the pressure by loosening the wing nut that | ||

turn. | ||

locks the pressure adjustment thumbscrew. Rotate the | ||

5. When the nut is no longer turning and the Pump | ||

thumbscrew clockwise to increase the pressure and | ||

Gauge reaches the preset pressure, release the remote | ||

counterclockwise to decrease the pressure. When | ||

control button. The piston rod will retract when the | ||

decreasing pressure, always lower the pressure below the | ||

button is released and under normal conditions, an | ||

desired point and then bring the gauge back up to the | ||

audible “click” will be heard as the tool resets itself. | ||

desired pressure. | ||

6. Continue to cycle the tool until it “stalls” and the | ||

4.When the desired pressure is reached, retighten the | ||

preset psi/torque has been attained. | ||

wing nut and cycle the tool again to confirm that the | ||

7. Once the nut stops rotating, cycle the tool one last | ||

desired pressure setting has been obtained. | ||

time to achieve total torque. | ||

|

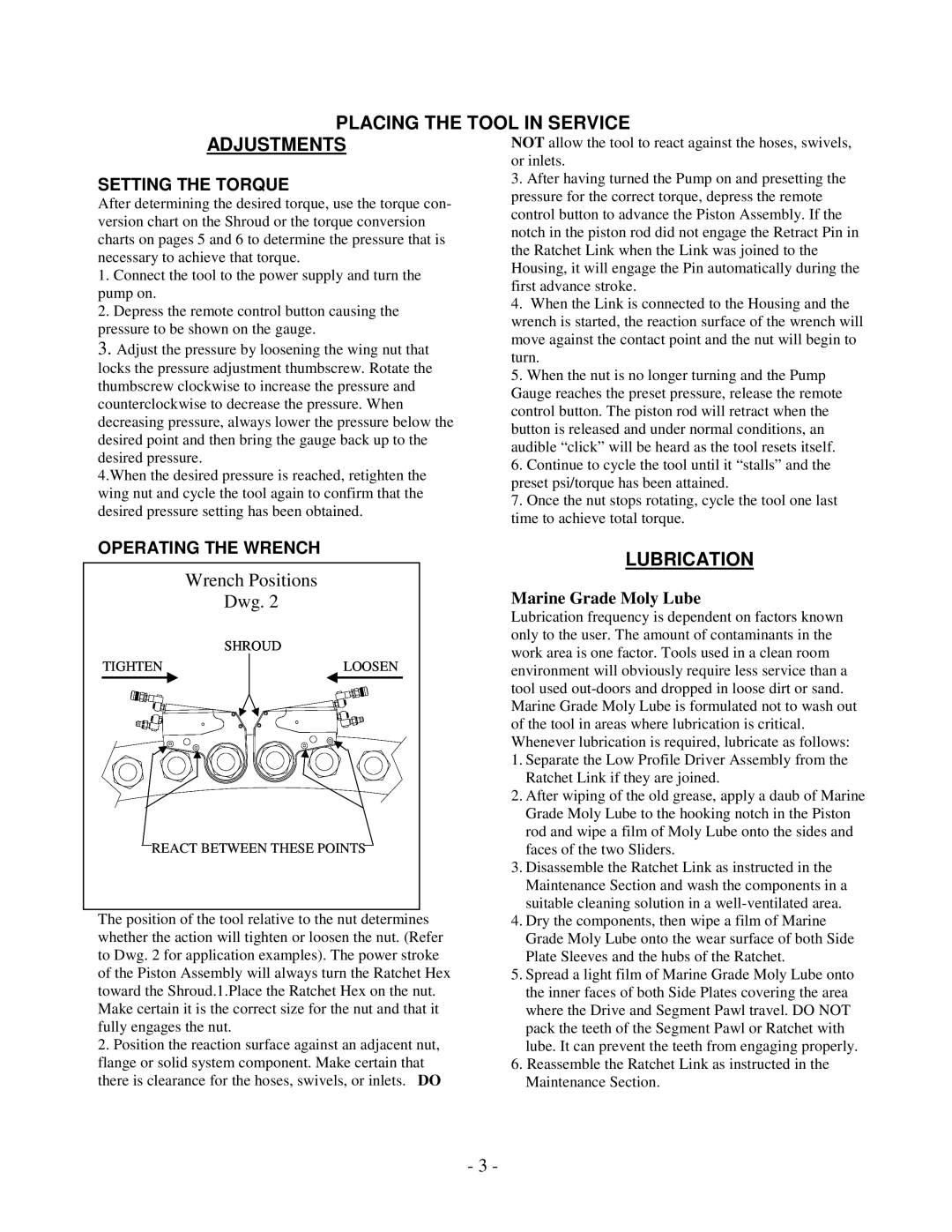

OPERATING THE WRENCH

Wrench Positions |

|

|

Dwg. 2 |

| Marine Grade Moly Lube |

|

| Lubrication frequency is dependent on factors known |

SHROUD |

| only to the user. The amount of contaminants in the |

| work area is one factor. Tools used in a clean room | |

|

| |

TIGHTEN | LOOSEN | environment will obviously require less service than a |

|

| |

|

| tool used |

|

| Marine Grade Moly Lube is formulated not to wash out |

|

| of the tool in areas where lubrication is critical. |

|

| Whenever lubrication is required, lubricate as follows: |

|

| 1. Separate the Low Profile Driver Assembly from the |

|

| Ratchet Link if they are joined. |

|

| 2. After wiping of the old grease, apply a daub of Marine |

|

| Grade Moly Lube to the hooking notch in the Piston |

|

| rod and wipe a film of Moly Lube onto the sides and |

REACT BETWEEN THESE POINTS | faces of the two Sliders. | |

|

| 3. Disassemble the Ratchet Link as instructed in the |

|

| Maintenance Section and wash the components in a |

|

| suitable cleaning solution in a |

The position of the tool relative to the nut determines | 4. Dry the components, then wipe a film of Marine | |

whether the action will tighten or loosen the nut. (Refer | Grade Moly Lube onto the wear surface of both Side | |

to Dwg. 2 for application examples). The power stroke | Plate Sleeves and the hubs of the Ratchet. | |

of the Piston Assembly will always turn the Ratchet Hex | 5. Spread a light film of Marine Grade Moly Lube onto | |

toward the Shroud.1.Place the Ratchet Hex on the nut. | the inner faces of both Side Plates covering the area | |

Make certain it is the correct size for the nut and that it | where the Drive and Segment Pawl travel. DO NOT | |

fully engages the nut. |

| pack the teeth of the Segment Pawl or Ratchet with |

2. Position the reaction surface against an adjacent nut, | lube. It can prevent the teeth from engaging properly. | |

flange or solid system component. Make certain that | 6. Reassemble the Ratchet Link as instructed in the | |

there is clearance for the hoses, swivels, or inlets. DO | Maintenance Section. | |

- 3 -