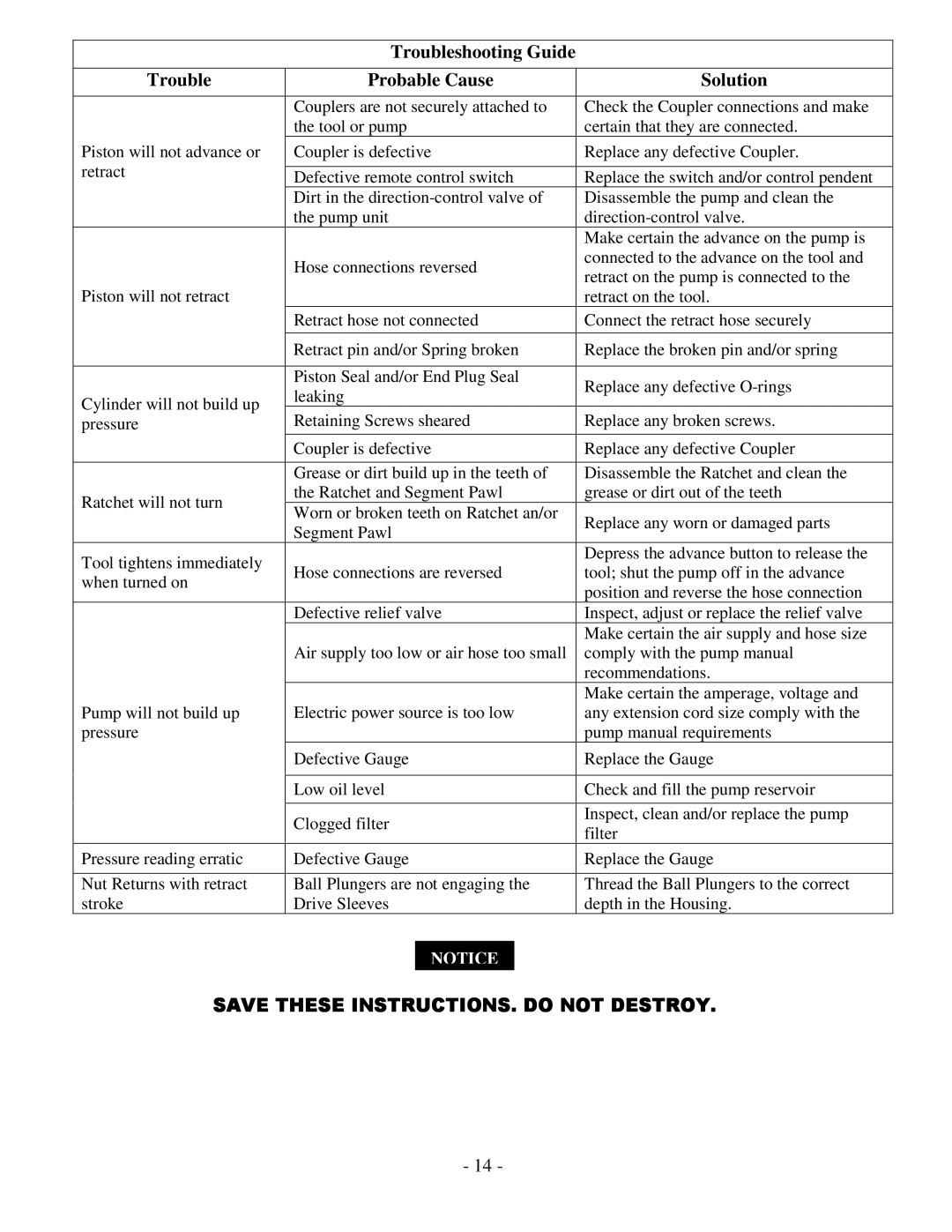

Troubleshooting Guide

| Trouble | Probable Cause | Solution |

|

|

|

|

|

| Couplers are not securely attached to | Check the Coupler connections and make |

|

| the tool or pump | certain that they are connected. |

| Piston will not advance or | Coupler is defective | Replace any defective Coupler. |

| retract |

|

|

| Defective remote control switch | Replace the switch and/or control pendent | |

|

| ||

|

| Dirt in the | Disassemble the pump and clean the |

|

| the pump unit | |

|

|

| Make certain the advance on the pump is |

|

| Hose connections reversed | connected to the advance on the tool and |

|

| retract on the pump is connected to the | |

|

|

| |

| Piston will not retract |

| retract on the tool. |

|

| Retract hose not connected | Connect the retract hose securely |

|

|

|

|

|

| Retract pin and/or Spring broken | Replace the broken pin and/or spring |

|

|

|

|

|

| Piston Seal and/or End Plug Seal | Replace any defective |

|

| leaking | |

| Cylinder will not build up |

| |

| Retaining Screws sheared | Replace any broken screws. | |

| pressure | ||

|

| Coupler is defective | Replace any defective Coupler |

|

|

|

|

|

| Grease or dirt build up in the teeth of | Disassemble the Ratchet and clean the |

| Ratchet will not turn | the Ratchet and Segment Pawl | grease or dirt out of the teeth |

| Worn or broken teeth on Ratchet an/or | Replace any worn or damaged parts | |

|

| ||

|

| Segment Pawl | |

|

|

| |

| Tool tightens immediately |

| Depress the advance button to release the |

| Hose connections are reversed | tool; shut the pump off in the advance | |

| when turned on | ||

|

| position and reverse the hose connection | |

|

|

| |

|

| Defective relief valve | Inspect, adjust or replace the relief valve |

|

|

| Make certain the air supply and hose size |

|

| Air supply too low or air hose too small | comply with the pump manual |

|

|

| recommendations. |

|

|

| Make certain the amperage, voltage and |

| Pump will not build up | Electric power source is too low | any extension cord size comply with the |

| pressure |

| pump manual requirements |

|

| Defective Gauge | Replace the Gauge |

|

|

|

|

|

| Low oil level | Check and fill the pump reservoir |

|

| Clogged filter | Inspect, clean and/or replace the pump |

|

| filter | |

|

|

| |

| Pressure reading erratic | Defective Gauge | Replace the Gauge |

|

|

|

|

| Nut Returns with retract | Ball Plungers are not engaging the | Thread the Ball Plungers to the correct |

| stroke | Drive Sleeves | depth in the Housing. |

NOTICE

SAVE THESE INSTRUCTIONS. DO NOT DESTROY.

- 14 -