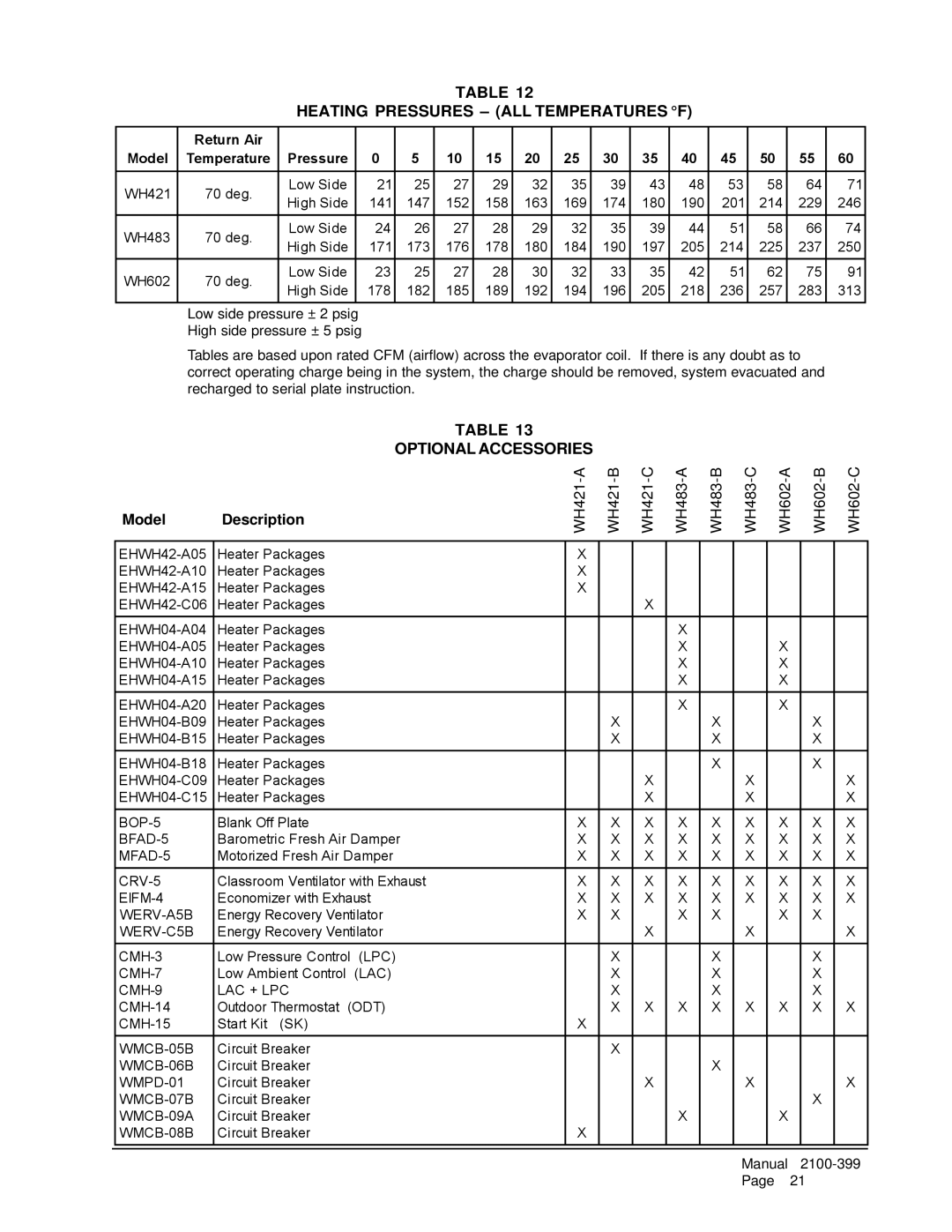

WH421, WH483, WH602 specifications

Bard WH602, WH421, and WH482 are distinguished models in Bard's line of high-performance wall-mounted heaters. Each unit is designed to offer reliable heating solutions for various commercial and industrial applications. These models are renowned for their energy efficiency, robust construction, and ease of use, making them ideal for a variety of environments, including warehouses, manufacturing facilities, and other large spaces.The WH602 model boasts impressive heating capabilities, featuring a powerful fan-forced heater equipped with a 60000 BTU rating. This allows it to effectively heat large areas quickly and efficiently. One of its main features is the high-efficiency, stainless steel heat exchanger that promotes better heat transfer, enhancing the overall performance and longevity of the heater. The WH602 is designed with energy-saving technology, allowing it to operate with minimal electricity consumption while maximizing output.

The WH421 model offers a more compact solution without sacrificing power. With a heating capacity of 42000 BTU, it is suitable for medium-sized spaces. Like the WH602, the WH421 utilizes a stainless steel heat exchanger, ensuring durability and efficient heating. This model is equipped with a quiet, high-performance fan that distributes heat uniformly throughout the space, maintaining comfortable conditions without the distraction of excessive noise. Its compact design also allows for easy installation in tighter spaces.

The WH482 is a versatile model that falls between the two in terms of performance and application. Rated at 48000 BTU, it combines the benefits of both the WH602 and WH421, making it suitable for various heating demands. The WH482 features advanced control options, allowing users to set specific heating schedules and temperatures for improved comfort and energy efficiency. Additionally, it has built-in safety features like over-temperature protection and a thermal cutoff switch, ensuring safe operation in commercial environments.

All three models share key characteristics, including a robust construction built to withstand harsh conditions, user-friendly controls, and compliance with industry safety standards. Their wall-mounted design saves valuable floor space while providing powerful heating performance. Overall, Bard WH602, WH421, and WH482 represent a commitment to quality, performance, and customer satisfaction, making them top choices for businesses seeking efficient heating solutions.