WH Series specifications

The Bard WH Series is a distinguished line of high-efficiency heating systems designed for commercial and industrial applications. Renowned for their performance and reliability, these heating units play a crucial role in providing optimal comfort and climate control in various settings, such as schools, offices, and manufacturing facilities.One of the standout features of the Bard WH Series is its efficient heat exchange technology. The series employs advanced heat exchanger designs that maximize thermal efficiency, ensuring that the units generate more heat with less energy consumption. This feature not only reduces overall energy costs but also minimizes carbon emissions, making it an environmentally friendly choice.

The WH Series incorporates a robust and durable construction. It is built to withstand demanding conditions often found in commercial environments. The cabinet is constructed from heavy-gauge steel which is coated with a corrosion-resistant finish, providing longevity and protection against harsh weather conditions. This rugged design ensures that the units continue to operate effectively even under heavy use.

Bard has integrated advanced control technologies into the WH Series, offering users precise temperature management. The intelligent control systems provide options for programmable settings, enabling users to customize heating schedules according to their needs. This capability not only enhances user comfort but also promotes energy savings by allowing the system to operate only when needed.

Another key characteristic of the Bard WH Series is its low noise operation. This is particularly important in settings where noise can be disruptive, such as schools or office environments. The series features quiet blowers and sound-attenuating designs that ensure minimal operational noise, allowing for a conducive environment even during peak heating periods.

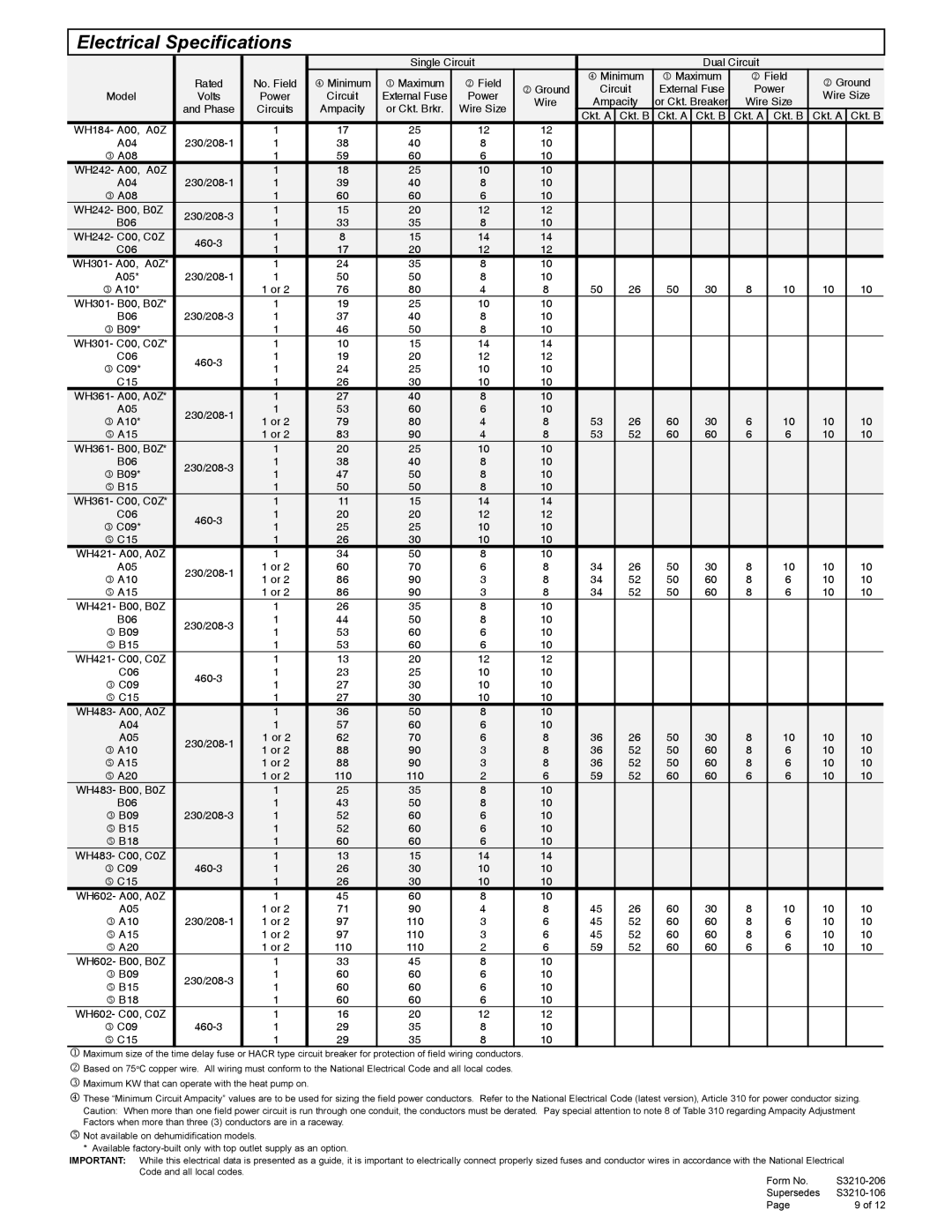

The WH Series also includes a range of models to meet diverse heating requirements. With different capacity options and configurations available, users can select the unit that best fits their specific space and heating demands. Additionally, the units can be easily integrated with existing HVAC systems, providing flexibility and convenience for installations.

In conclusion, the Bard WH Series is engineered to deliver superior heating performance while emphasizing efficiency, durability, and user comfort. Its combination of cutting-edge technology, robust construction, and design considerations makes it a preferred choice for those seeking reliable heating solutions in commercial and industrial settings.