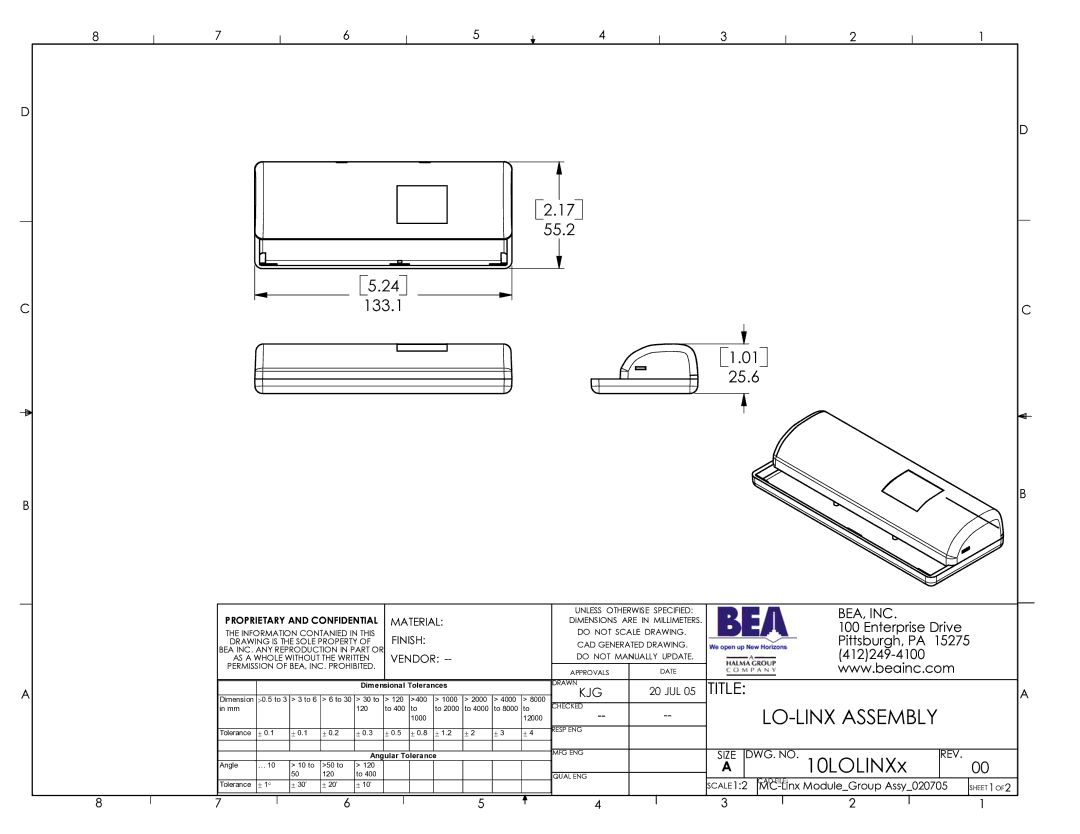

LO Linx Assembly specifications

BEA LO Linx Assembly is an innovative technology designed to revolutionize the process of creating modular and scalable electronic systems. This assembly is distinguished by its unique approach in integrating various components, enabling engineers and designers to streamline production and enhance efficiency. The assembly process is ideal for applications in various domains, including consumer electronics, automotive systems, industrial machinery, and medical devices.One of the main features of BEA LO Linx Assembly is its focus on modular design principles. By utilizing interchangeable modules, manufacturers can easily customize products to meet specific requirements, significantly reducing lead times and costs. This modularity allows for easy upgrades and maintenance, which is paramount in rapidly evolving tech landscapes. Furthermore, the assembly supports a variety of form factors, accommodating both compact and large-scale devices.

Technologically, the BEA LO Linx Assembly leverages advanced materials and manufacturing processes. The use of lightweight materials not only enhances the overall performance of the assembly but also contributes to energy savings and improved sustainability. Additionally, the assembly incorporates smart technologies, such as sensors and IoT connectivity, facilitating real-time data collection and monitoring. This capability enables predictive maintenance and better decision-making for users.

The characteristics of the BEA LO Linx Assembly further highlight its versatility. The assembly is designed to operate under a wide range of environmental conditions, ensuring reliability even in challenging scenarios. This includes being resistant to temperature fluctuations, humidity, and vibration, making it suitable for diverse applications. The assembly also adheres to stringent safety and compliance standards, ensuring that products are safe for end-users and compliant with industry regulations.

In summary, BEA LO Linx Assembly stands out for its modular design, advanced technologies, and robust characteristics. By enabling easy customization and integration, it empowers manufacturers to stay competitive in a dynamic market environment. As industries continue to demand smarter, more efficient solutions, the BEA LO Linx Assembly is poised to play a vital role in the future of electronic systems design. Its ability to adapt, innovate, and respond to market needs makes it a cornerstone of modern electronic assembly practices.