AFG Oil Burner specifications

The Beckett AFG Oil Burner stands as a top choice for residential and commercial heating applications, recognized for its reliability, efficiency, and innovation. Engineered to deliver optimal performance, this burner has become a market favorite among HVAC professionals and homeowners alike.One of the standout features of the AFG Oil Burner is its advanced technology for efficient fuel combustion. The burner employs a unique air-fuel ratio control system, which ensures precise mixing of air and oil for maximum efficiency. This not only enhances heating performance but also contributes to significant fuel savings, making it an environmentally friendly option.

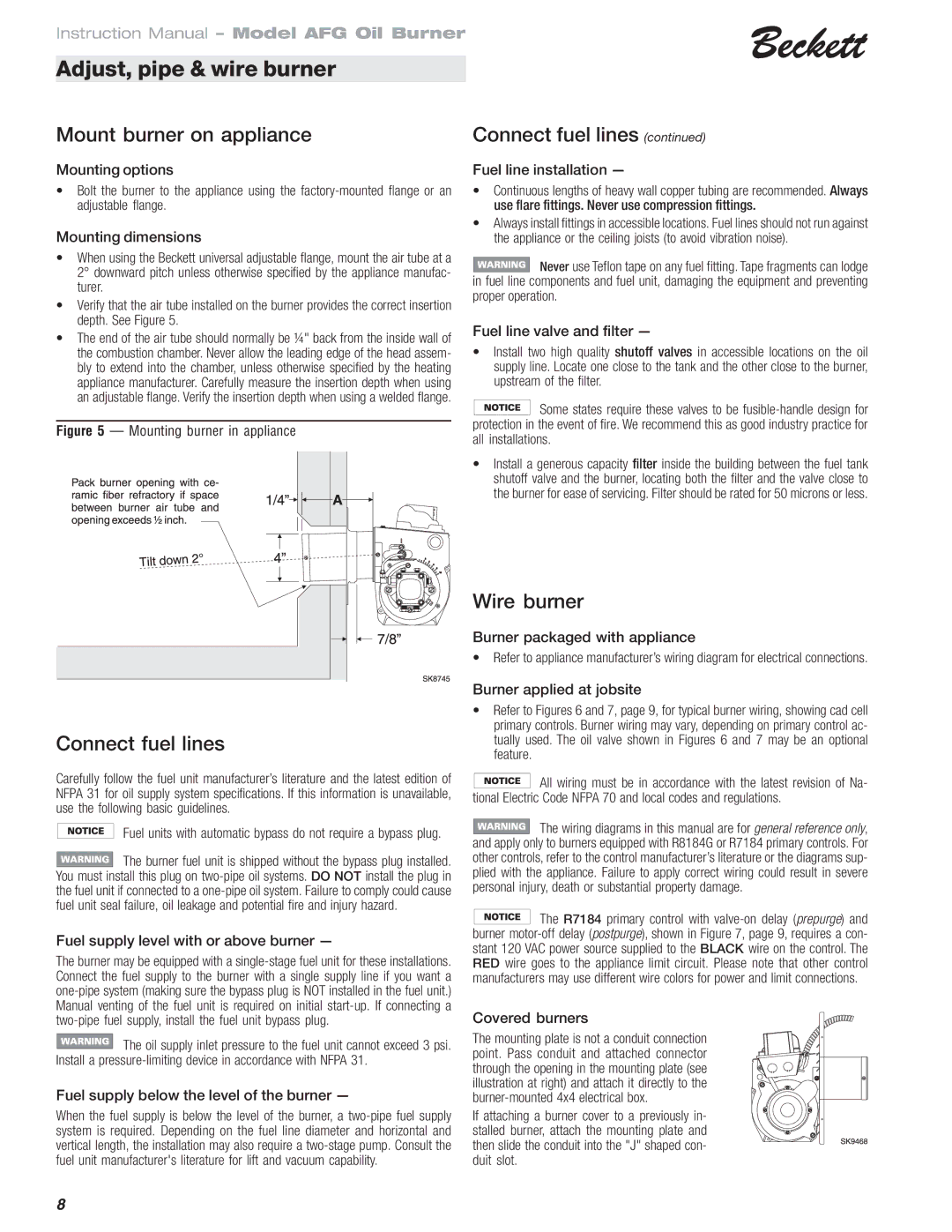

The Beckett AFG is designed with a compact, lightweight structure, facilitating easy installation and maintenance. Its proprietary design minimizes noise levels during operation, providing a quiet heating solution ideal for residential settings. The burner also features an automatic reset capability, which enhances safety by shutting off in the case of an operational fault, thus preventing potential hazards.

Another noteworthy characteristic of the AFG Oil Burner is its versatile application range. It supports various oil types, including No. 1 and No. 2 fuel oils, making it suitable for different heating requirements. The burner’s adaptability extends to various applications, including forced hot air, hot water boilers, and steam systems.

In terms of performance, the AFG model boasts impressive firing rates, providing up to 3.5 GPH, suitable for both small homes and larger commercial establishments. Its ability to maintain consistent fuel flow helps reduce wear and tear on the heating system, extending its longevity.

The user-friendly feature of the Beckett AFG includes an advanced ignition system that ensures quick and reliable startups. This system dramatically decreases the risk of ignition failures, providing peace of mind for users.

Furthermore, Beckett's commitment to quality is evident in the robust construction of the AFG Oil Burner. Made from high-grade materials, this burner is built to withstand the rigors of frequent operation.

In summary, the Beckett AFG Oil Burner is a high-performance, energy-efficient solution that combines advanced technology, safety features, and versatile applications. Its dependability and efficiency make it an excellent investment for anyone seeking effective heating solutions.