|

|

|

|

|

|

|

| Maintenance |

| |

| Brake Adjuster |

|

|

|

| |||||

| Service Intervals |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |||

| Component |

| Visual Inspection |

| Lubrication Interval | Type of Lubricant |

| |||

|

|

|

|

|

|

|

|

|

|

|

| Standard |

|

|

|

|

| Adjusters manufactured prior to 6/1/96 – |

|

|

|

|

|

| During normal | chassis |

| every 50,000 miles or every 3 months. | Standard Chassis Grease |

| ||

|

|

|

| Adjusters manufactured |

| |||||

|

|

| lubrication | or 3 | months |

|

|

|

| |

|

|

|

| after 6/1/96 – once a year. |

|

|

| |||

|

|

| which ever | occures first. |

|

|

|

| ||

| Low Lube |

|

| Once a year | SHC 460 | Synthetic |

| |||

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| Lube Free |

|

|

|

|

| None | *Lubricated | at Factory |

|

|

|

|

|

|

|

| ||||

| *Lube free Spicer® brand self adjusting brake adjusters are manufactured without a grease fitting. |

|

|

| ||||||

Lubrication

Caution: Do not use

Important: In no case should the lubrication interval exceed the published intervals in table above.

Lube Free Spicer® brand self adjusting brake adjusters are lubricated at the factory with a proprietary grease and do not require lubrication at service intervals.

Note: Spicer® brand self adjusting brake adjusters manufactured after May 30, 1996 have incorporated an improved sealing and grease filling technique. This makes it possible to extend service

intervals, thus reducing maintenance.

Inspection

Bendix Spicer Foundation Brake strongly recommends that routine visual/operational checks, including brackets and control arms, be performed at each Preventative Maintenance Service Interval.

Adjusters or anchor brackets that have visual damage, or which fail the operational checks, MUST be replaced immediately.

Inspect brake adjuster and anchor bracket for damage. Check that anchor bracket is tight and the control arm is in the full release position.

Note: If self adjusting brake adjuster is equipped with indicator arrow, make sure the indicator is within the slow when the brake is in the release position.

Automatic adjusters should not be operated as manual adjusters except as may be necessary to get the vehicle off the road for service.

Maintaining proper brake adjustment and brake balance cannot

be accomplished by the brake adjuster alone. The condition of founda- tion brake components have a direct bearing on the

effectiveness of brake adjustment. Inspect foundation brake components periodically.

Brake Air Chambers

Check that brake air chamber mounting bolts are tight and properly aligned to avoid interference between air chamber pushrod and air chamber housing.

Verify that brake chamber pushrod length is equal on both brake chambers of the same axle.

Camshaft Bushings

Worn “S” cam bushings will increase push rod travel. Replace bushing if worn and at each reline.

For detailed inspection procedure on foundation brake components refer to Bendix Spicer Foundation Brake service manual BW7258.

Wheel Bearing Adjustment

Accurate wheel bearing preload is necessary to maintain proper alignment between the brake drum and brake shoes.

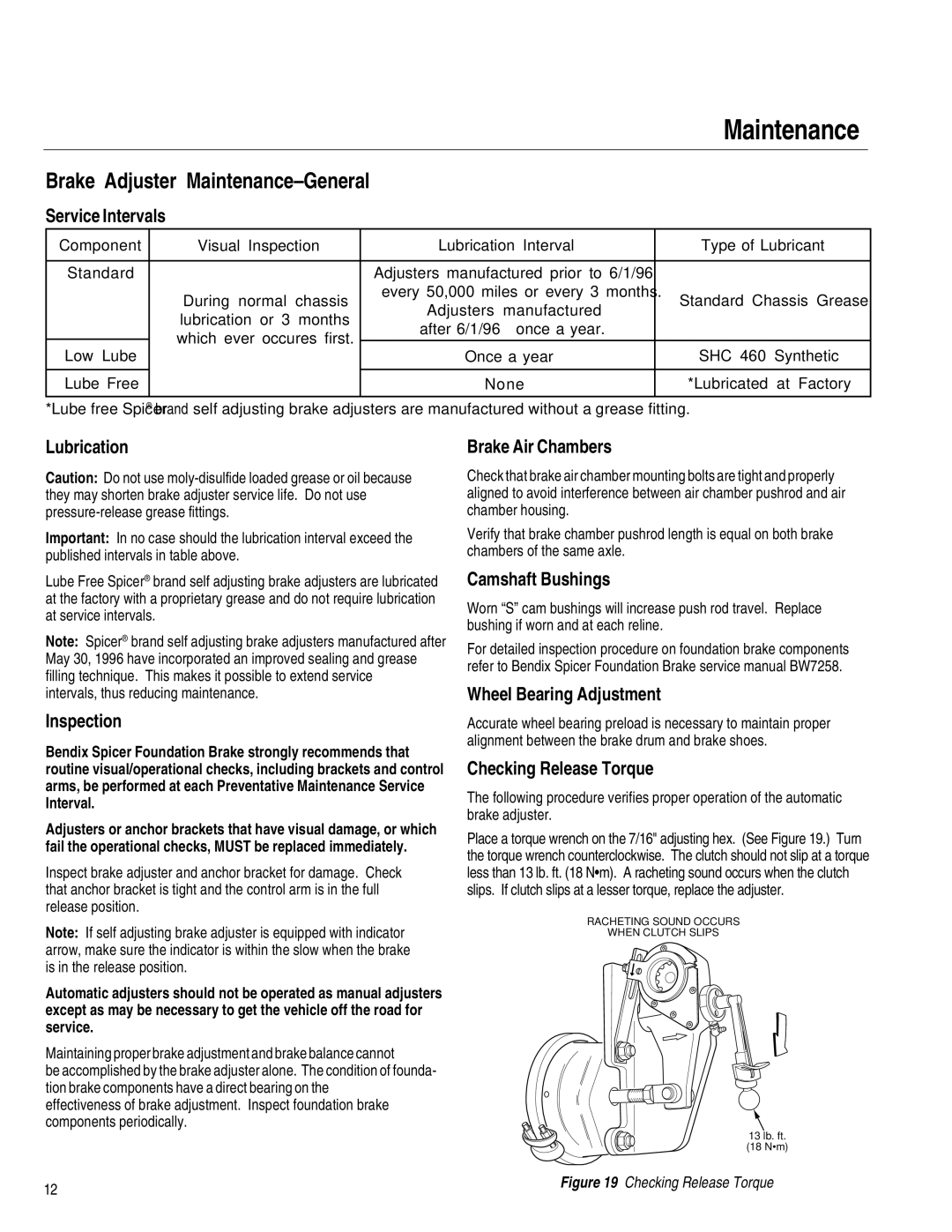

Checking Release Torque

The following procedure verifies proper operation of the automatic brake adjuster.

Place a torque wrench on the 7/16" adjusting hex. (See Figure 19.) Turn the torque wrench counterclockwise. The clutch should not slip at a torque less than 13 lb. ft. (18 N•m). A racheting sound occurs when the clutch slips. If clutch slips at a lesser torque, replace the adjuster.

RACHETING SOUND OCCURS

WHEN CLUTCH SLIPS

13 lb. ft.

(18 N•m)

12 | Figure 19 Checking Release Torque |

|