SPRING BRAKE

CYCLONE DURADRAIN™ |

|

| |

TRAILER WATER |

|

| |

SEPARATOR |

|

| |

|

| CONTROL |

|

|

| SUPPLY | ABS UNIT OR |

|

| ||

|

| ||

PLACEMENT OF OPTIONAL | RELAY VALVE | ||

| |||

SUPPLY LINE CYCLONE | BRAKE VALVE |

| |

DURADRAIN™ TRAILER WATER |

|

| |

SEPARATOR |

|

| |

|

|

|

|

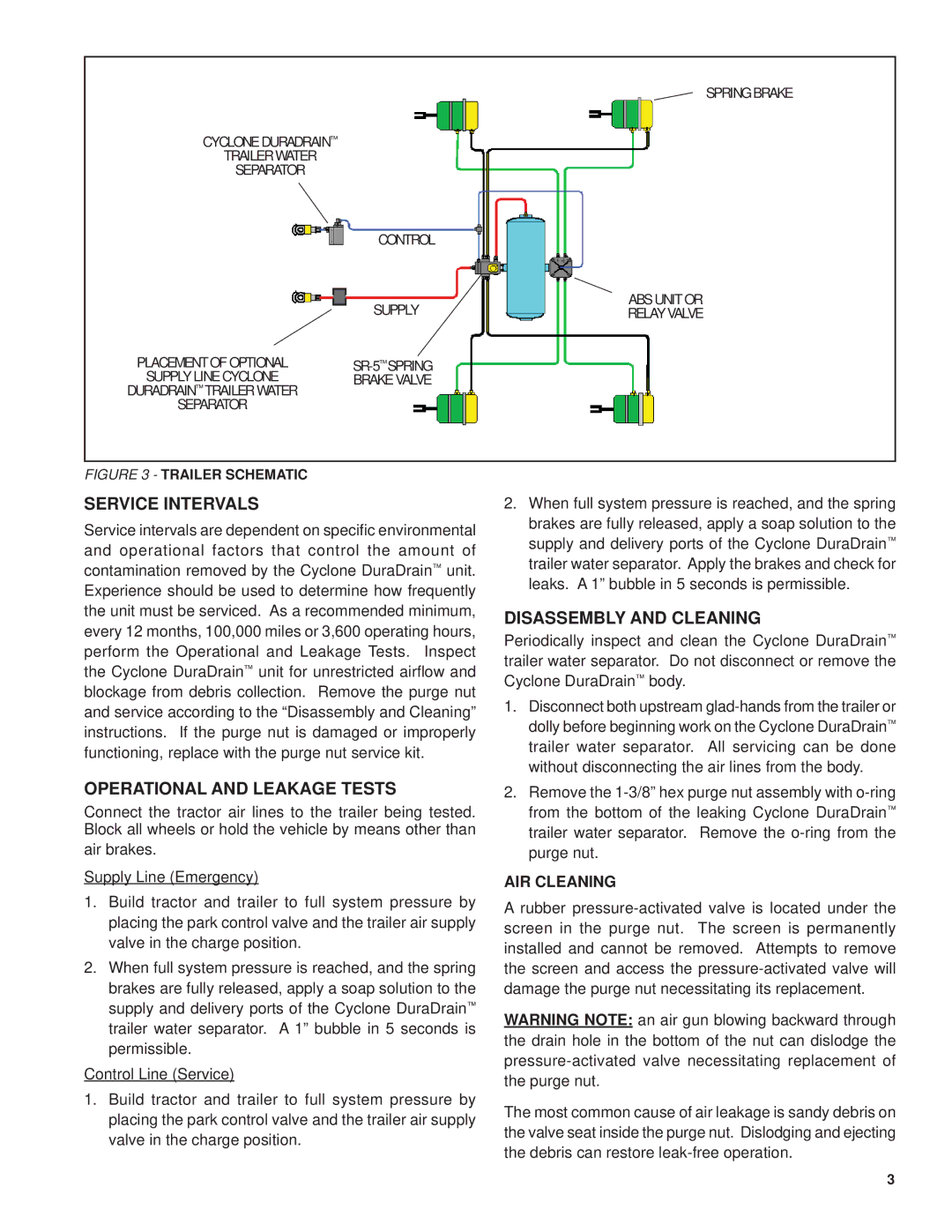

FIGURE 3 - TRAILER SCHEMATIC |

|

| |

SERVICE INTERVALS

Service intervals are dependent on specific environmental and operational factors that control the amount of contamination removed by the Cyclone DuraDrain™ unit. Experience should be used to determine how frequently the unit must be serviced. As a recommended minimum, every 12 months, 100,000 miles or 3,600 operating hours, perform the Operational and Leakage Tests. Inspect the Cyclone DuraDrain™ unit for unrestricted airflow and blockage from debris collection. Remove the purge nut and service according to the “Disassembly and Cleaning” instructions. If the purge nut is damaged or improperly functioning, replace with the purge nut service kit.

OPERATIONAL AND LEAKAGE TESTS

Connect the tractor air lines to the trailer being tested. Block all wheels or hold the vehicle by means other than

air brakes.

Supply Line (Emergency)

1.Build tractor and trailer to full system pressure by placing the park control valve and the trailer air supply valve in the charge position.

2.When full system pressure is reached, and the spring brakes are fully released, apply a soap solution to the supply and delivery ports of the Cyclone DuraDrain™ trailer water separator. A 1” bubble in 5 seconds is permissible.

Control Line (Service)

1.Build tractor and trailer to full system pressure by placing the park control valve and the trailer air supply valve in the charge position.

2.When full system pressure is reached, and the spring brakes are fully released, apply a soap solution to the supply and delivery ports of the Cyclone DuraDrain™ trailer water separator. Apply the brakes and check for leaks. A 1” bubble in 5 seconds is permissible.

DISASSEMBLY AND CLEANING

Periodically inspect and clean the Cyclone DuraDrain™ trailer water separator. Do not disconnect or remove the Cyclone DuraDrain™ body.

1.Disconnect both upstream

2.Remove the

AIR CLEANING

A rubber

WARNING NOTE: an air gun blowing backward through the drain hole in the bottom of the nut can dislodge the

The most common cause of air leakage is sandy debris on the valve seat inside the purge nut. Dislodging and ejecting the debris can restore

3