COMPRESSOROIL COALESCING

FILTER

CONTROL

LINE

DESICCANT

BED

PURGE

ORIFICE

PURGE AIR

Note 1:

The Bendix®

CONTROL |

| EXTENDED |

|

PORT |

|

| |

TURBO |

| PURGE |

|

| PORT | REAR | |

|

| ||

VALVE |

| DELIVERY | RESERVOIR |

(OPEN) |

|

| |

|

| CHECK |

|

|

| VALVE |

|

SUPPLY |

|

|

|

PORT |

|

|

|

SAFETY |

|

| FRONT |

VALVE | EXHAUST |

| RESERVOIR |

| PURGE |

|

|

| VALVE | DELIVERY |

|

| GOVERNOR |

| |

| PORT |

| |

| EXHAUST |

|

|

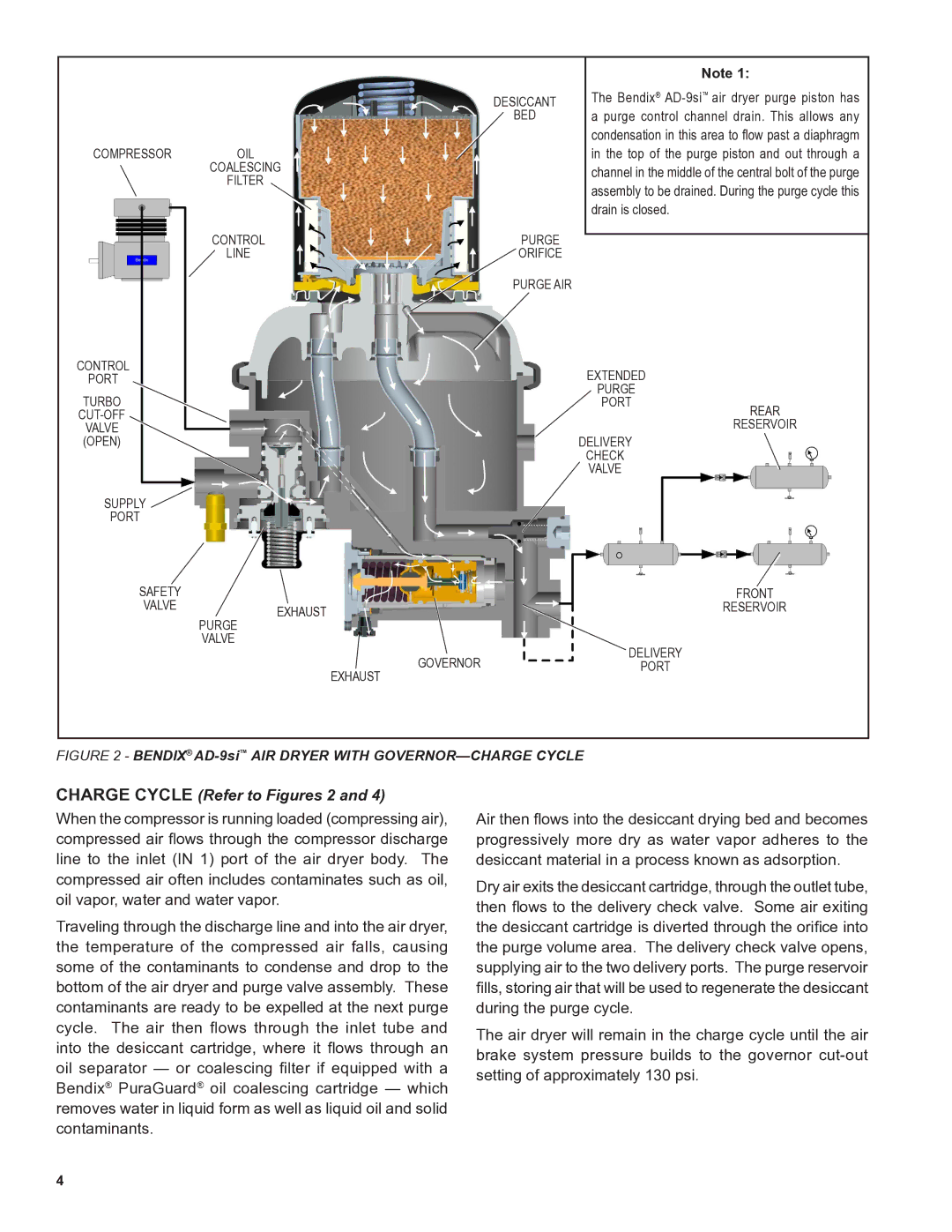

FIGURE 2 - BENDIX® AD-9si™ AIR DRYER WITH GOVERNOR—CHARGE CYCLE

CHARGE CYCLE (Refer to Figures 2 and 4)

When the compressor is running loaded (compressing air), compressed air flows through the compressor discharge line to the inlet (IN 1) port of the air dryer body. The compressed air often includes contaminates such as oil, oil vapor, water and water vapor.

Traveling through the discharge line and into the air dryer, the temperature of the compressed air falls, causing some of the contaminants to condense and drop to the bottom of the air dryer and purge valve assembly. These contaminants are ready to be expelled at the next purge cycle. The air then flows through the inlet tube and into the desiccant cartridge, where it flows through an oil separator — or coalescing filter if equipped with a Bendix® PuraGuard® oil coalescing cartridge — which removes water in liquid form as well as liquid oil and solid contaminants.

Air then flows into the desiccant drying bed and becomes progressively more dry as water vapor adheres to the desiccant material in a process known as adsorption.

Dry air exits the desiccant cartridge, through the outlet tube, then flows to the delivery check valve. Some air exiting the desiccant cartridge is diverted through the orifice into the purge volume area. The delivery check valve opens, supplying air to the two delivery ports. The purge reservoir fills, storing air that will be used to regenerate the desiccant during the purge cycle.

The air dryer will remain in the charge cycle until the air brake system pressure builds to the governor

4