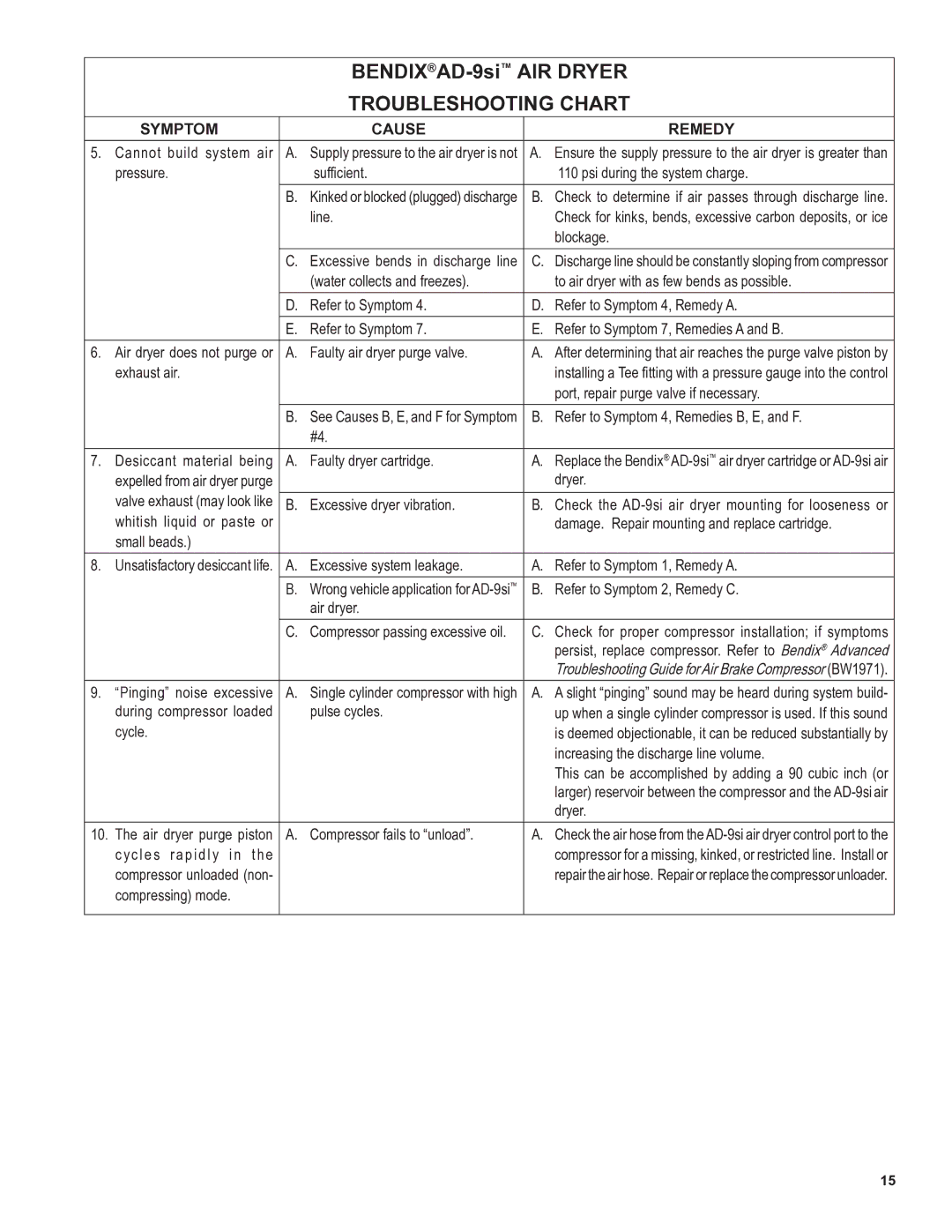

TROUBLESHOOTING CHART

| SYMPTOM |

| CAUSE |

| REMEDY |

5. | Cannot build system air | A. | Supply pressure to the air dryer is not | A. | Ensure the supply pressure to the air dryer is greater than |

| pressure. |

| sufficient. |

| 110 psi during the system charge. |

|

| B. | Kinked or blocked (plugged) discharge | B. | Check to determine if air passes through discharge line. |

|

|

| line. |

| Check for kinks, bends, excessive carbon deposits, or ice |

|

|

|

|

| blockage. |

|

| C. | Excessive bends in discharge line | C. Discharge line should be constantly sloping from compressor | |

|

|

| (water collects and freezes). |

| to air dryer with as few bends as possible. |

|

| D. Refer to Symptom 4. | D. Refer to Symptom 4, Remedy A. | ||

|

| E. Refer to Symptom 7. | E. Refer to Symptom 7, Remedies A and B. | ||

6. Air dryer does not purge or | A. | Faulty air dryer purge valve. | A. | After determining that air reaches the purge valve piston by | |

| exhaust air. |

|

|

| installing a Tee fitting with a pressure gauge into the control |

|

|

|

|

| port, repair purge valve if necessary. |

|

| B. | See Causes B, E, and F for Symptom | B. | Refer to Symptom 4, Remedies B, E, and F. |

|

|

| #4. |

|

|

7. | Desiccant material being | A. | Faulty dryer cartridge. | A. | Replace the Bendix® |

| expelled from air dryer purge |

|

|

| dryer. |

| valve exhaust (may look like |

|

|

|

|

| B. | Excessive dryer vibration. | B. | Check the | |

| whitish liquid or paste or |

|

|

| damage. Repair mounting and replace cartridge. |

| small beads.) |

|

|

|

|

8. | Unsatisfactory desiccant life. | A. | Excessive system leakage. | A. Refer to Symptom 1, Remedy A. | |

|

| B. Wrong vehicle application for | B. | Refer to Symptom 2, Remedy C. | |

|

|

| air dryer. |

|

|

|

| C. | Compressor passing excessive oil. | C. | Check for proper compressor installation; if symptoms |

|

|

|

|

| persist, replace compressor. Refer to Bendix® Advanced |

|

|

|

|

| Troubleshooting Guide for Air Brake Compressor (BW1971). |

9. | “Pinging” noise excessive | A. | Single cylinder compressor with high | A. | A slight “pinging” sound may be heard during system build- |

| during compressor loaded |

| pulse cycles. |

| up when a single cylinder compressor is used. If this sound |

| cycle. |

|

|

| is deemed objectionable, it can be reduced substantially by |

|

|

|

|

| increasing the discharge line volume. |

|

|

|

|

| This can be accomplished by adding a 90 cubic inch (or |

|

|

|

|

| larger) reservoir between the compressor and the |

|

|

|

|

| dryer. |

10. The air dryer purge piston | A. | Compressor fails to “unload”. | A. Check the air hose from the | ||

| c y c l e s r a p i d l y i n t h e |

|

|

| compressor for a missing, kinked, or restricted line. Install or |

| compressor unloaded (non- |

|

|

| repair the air hose. Repair or replace the compressor unloader. |

| compressing) mode. |

|

|

|

|

|

|

|

|

|

|

15