IMPORTANT INFORMATION CONCERNING THE INSTALLATION OF THE APPLIANCE

We inform the installer that this hob is of the Y type and thus it can be installed by itself, in an isolated position or inserted between two kitchen units or between one kitchen unit and a wall. Furthermore the back wall and surrounding surfaces must resist a temperature of 65 K.

To prevent the plastic layer which covers the kitchen unit from ungluing, the glue used to join the two surfaces together must resist temperatures of up to 150 °C

The installation of the appliance must be carried out according to the norms in force of the country concerned and the appliance must be installed in a well ventilated place.

This appliance is not equipped with devices to remove the products of combustion. The appliance must therefore be connected following the norms for installation mentioned above. Special attention must be paid to the information below regarding aeration and ventilation of the premises.

VENTILATION OF THE PREMISES

To guarantee that the appliance works correctly it is necessary that the place where the appliance is installed is continuously ventilated. The volume of the premises must not be less than 25 m³ and the quantity of air needed must be based on the regular combustion of gas and on the ventilation of the premises. The natural flow of air will take place through permanent openings made in the wall of the premises to be ventilated: these openings will be connected to the outside and must have a minimum section of 100 cm² ( see Fig. 4 ).

These openings must be made in such a way that they cannot be obstructed.

POSITION AND VENTILATION

The cooking appliances that use gas must always remove the products of combustion via a hood linked to chimneys, chimney flues or via a direct connection to the outside ( see Fig. 5A ). If it is not possible to fit a hood it is possible to use a fan, fitted on the window or facing directly outside, which operates when the appliance is in use. ( see Fig. 5B ). In this way the norms in force of the country concerned regarding the ventilation of premises are strictly followed.

CONNECTING THE APPLIANCE TO THE GAS SUPPLY

Before connecting the appliance to the gas supply you first need to remove the plastic protective plug for the gas supply which is inserted under pressure in the gas inlet connection. To remove the plug simply unscrew it.

Then make sure that the details shown on the label on the lower part of the case are compatible with those of the gas supply. A label on the last page of this manual and on the lower part of the case indicates the conditions for regulating the appliance: type of gas and pressure used.

IMPORTANT: This appliance must be installed in accordance with the norms in force of the country concerned and it must only be used in a

ATTENTION: Remember that the gas inlet connection for the appliance is threaded 1/2 gas cylindrical male in accordance with the norms

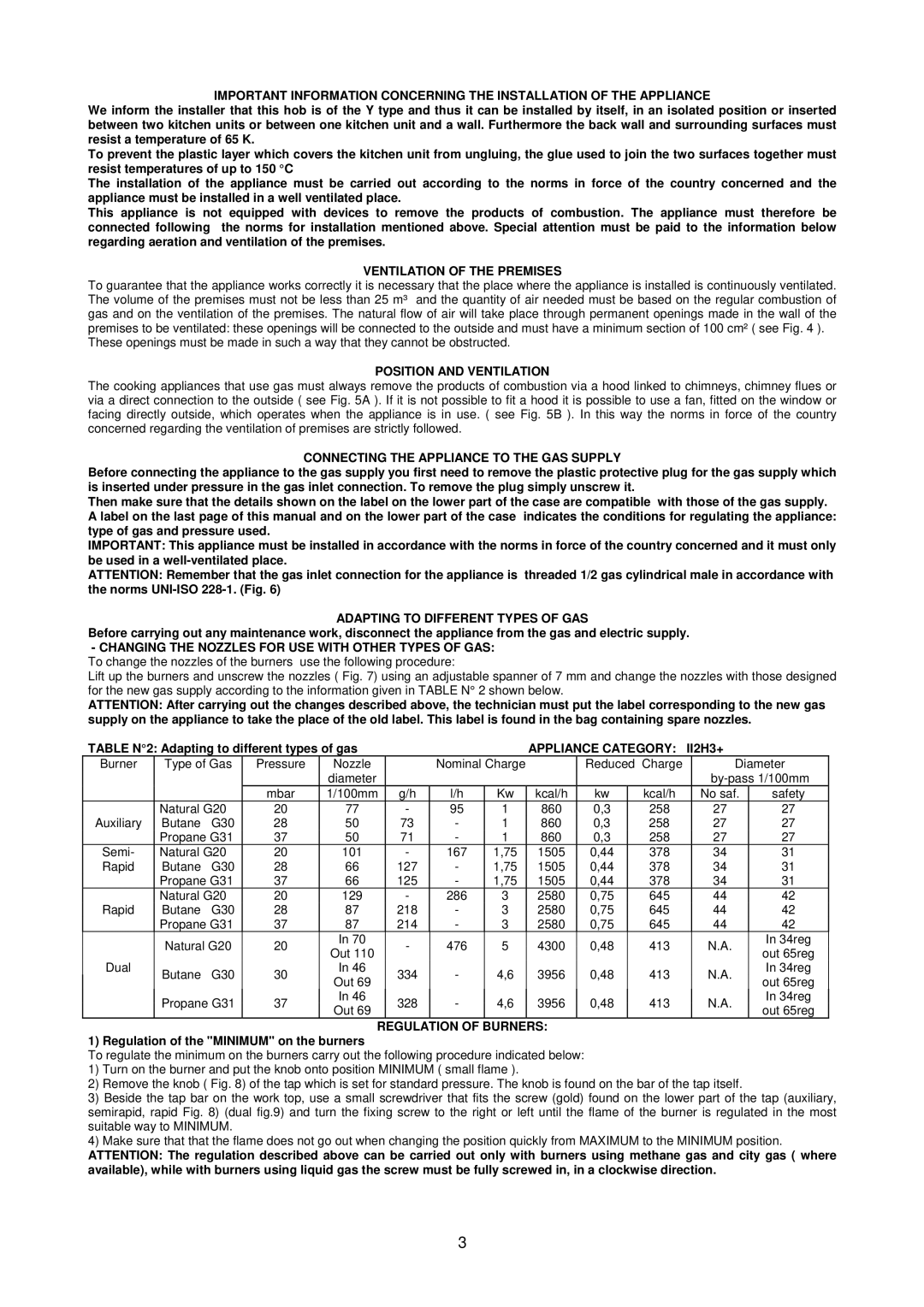

ADAPTING TO DIFFERENT TYPES OF GAS

Before carrying out any maintenance work, disconnect the appliance from the gas and electric supply.

-CHANGING THE NOZZLES FOR USE WITH OTHER TYPES OF GAS: To change the nozzles of the burners use the following procedure:

Lift up the burners and unscrew the nozzles ( Fig. 7) using an adjustable spanner of 7 mm and change the nozzles with those designed for the new gas supply according to the information given in TABLE N° 2 shown below.

ATTENTION: After carrying out the changes described above, the technician must put the label corresponding to the new gas supply on the appliance to take the place of the old label. This label is found in the bag containing spare nozzles.

TABLE N°2: Adapting to different types of gas |

|

|

| APPLIANCE CATEGORY: | II2H3+ |

| ||||||

Burner | Type of Gas | Pressure | Nozzle |

| Nominal Charge |

| Reduced Charge |

| Diameter | |||

|

|

| diameter |

|

|

|

|

|

|

| ||

|

| mbar | 1/100mm | g/h | l/h | Kw | kcal/h | kw | kcal/h |

| No saf. | safety |

| Natural G20 | 20 | 77 | - | 95 | 1 | 860 | 0,3 | 258 |

| 27 | 27 |

Auxiliary | Butane G30 | 28 | 50 | 73 | - | 1 | 860 | 0,3 | 258 |

| 27 | 27 |

| Propane G31 | 37 | 50 | 71 | - | 1 | 860 | 0,3 | 258 |

| 27 | 27 |

Semi- | Natural G20 | 20 | 101 | - | 167 | 1,75 | 1505 | 0,44 | 378 |

| 34 | 31 |

Rapid | Butane G30 | 28 | 66 | 127 | - | 1,75 | 1505 | 0,44 | 378 |

| 34 | 31 |

| Propane G31 | 37 | 66 | 125 | - | 1,75 | 1505 | 0,44 | 378 |

| 34 | 31 |

| Natural G20 | 20 | 129 | - | 286 | 3 | 2580 | 0,75 | 645 |

| 44 | 42 |

Rapid | Butane G30 | 28 | 87 | 218 | - | 3 | 2580 | 0,75 | 645 |

| 44 | 42 |

| Propane G31 | 37 | 87 | 214 | - | 3 | 2580 | 0,75 | 645 |

| 44 | 42 |

| Natural G20 | 20 | In 70 | - | 476 | 5 | 4300 | 0,48 | 413 |

| N.A. | In 34reg |

| Out 110 |

| out 65reg | |||||||||

|

|

|

|

|

|

|

|

|

|

| ||

Dual | Butane G30 | 30 | In 46 | 334 | - | 4,6 | 3956 | 0,48 | 413 |

| N.A. | In 34reg |

| Out 69 |

| out 65reg | |||||||||

|

|

|

|

|

|

|

|

|

|

| ||

| Propane G31 | 37 | In 46 | 328 | - | 4,6 | 3956 | 0,48 | 413 |

| N.A. | In 34reg |

| Out 69 |

| out 65reg | |||||||||

|

|

|

|

|

|

|

|

|

|

| ||

REGULATION OF BURNERS:

1) Regulation of the "MINIMUM" on the burners

To regulate the minimum on the burners carry out the following procedure indicated below:

1)Turn on the burner and put the knob onto position MINIMUM ( small flame ).

2)Remove the knob ( Fig. 8) of the tap which is set for standard pressure. The knob is found on the bar of the tap itself.

3)Beside the tap bar on the work top, use a small screwdriver that fits the screw (gold) found on the lower part of the tap (auxiliary, semirapid, rapid Fig. 8) (dual fig.9) and turn the fixing screw to the right or left until the flame of the burner is regulated in the most suitable way to MINIMUM.

4)Make sure that that the flame does not go out when changing the position quickly from MAXIMUM to the MINIMUM position.

ATTENTION: The regulation described above can be carried out only with burners using methane gas and city gas ( where available), while with burners using liquid gas the screw must be fully screwed in, in a clockwise direction.

3