17MAINTENANCE continued

17.1IMPELLER REMOVAL continued

9.To reinstall impeller, use a new impeller bolt and lockwasher and use exactly the same crankshaft impeller shim washers as were removed during disassembly (unless they were damaged). Note: your unit may or may not have required the use of shim washers.

10. Tighten impeller bolt. Torque impeller bolt to 50 Ft. Lbs. (68 N.m) (see item 51 on page 11).

11.Reinstall engine and impeller onto housing in reverse order of removal.

12.Before connecting spark plug wire, slowly pull engine starting rope to insure that impeller rotates freely.

13. Reinstall spark plug wire.

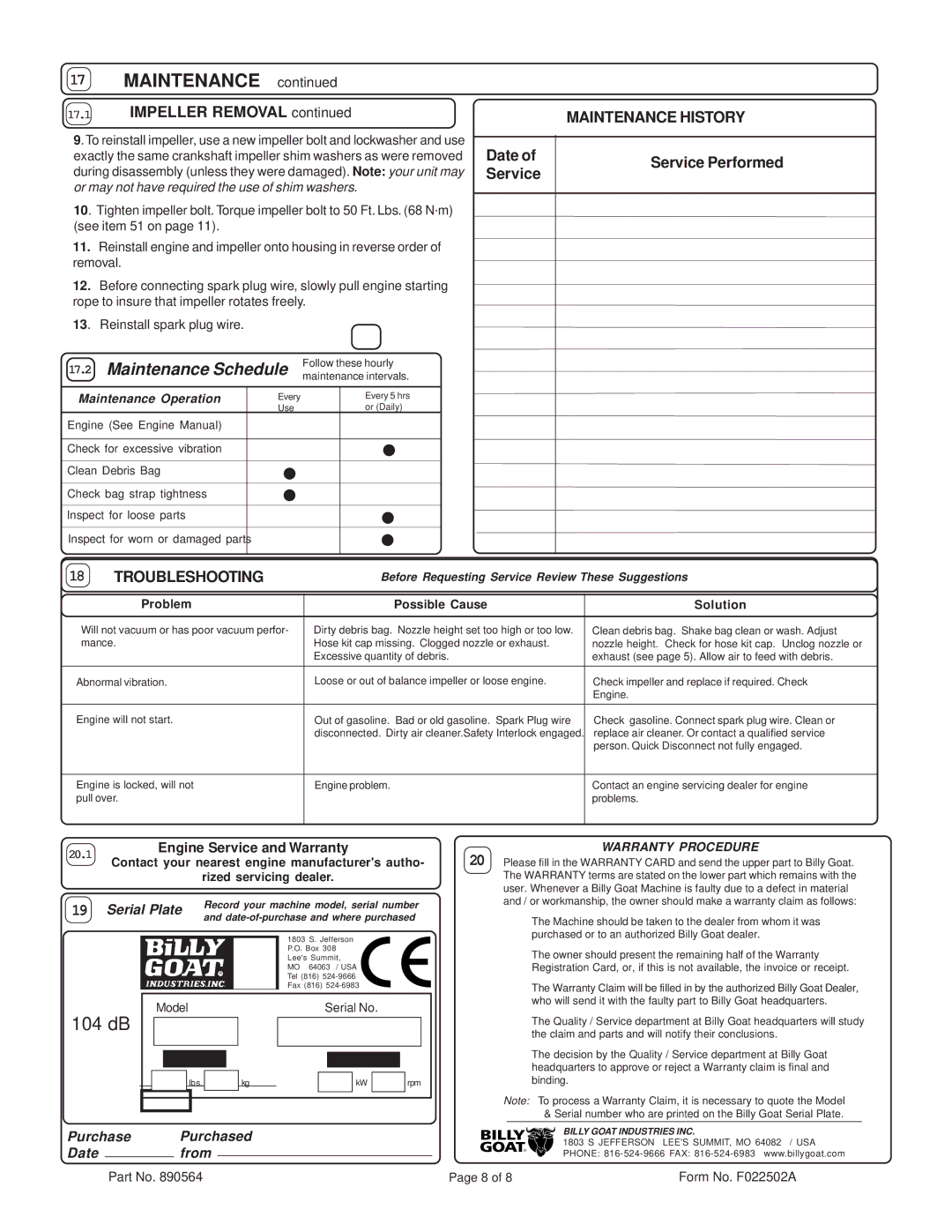

17.2 Maintenance Schedule | Follow these hourly | ||

maintenance intervals. | |||

|

| ||

|

|

| |

Maintenance Operation | Every | Every 5 hrs | |

| Use | or (Daily) | |

Engine (See Engine Manual)

Check for excessive vibration

Clean Debris Bag

Check bag strap tightness

Inspect for loose parts

Inspect for worn or damaged parts

MAINTENANCE HISTORY

Date of | Service Performed | |

Service | ||

| ||

|

| |

|

| |

|

|

18TROUBLESHOOTING

Problem

Before Requesting Service Review These Suggestions

Possible Cause | Solution |

|

|

Will not vacuum or has poor vacuum perfor- | Dirty debris bag. Nozzle height set too high or too low. | Clean debris bag. Shake bag clean or wash. Adjust |

mance. | Hose kit cap missing. Clogged nozzle or exhaust. | nozzle height. Check for hose kit cap. Unclog nozzle or |

| Excessive quantity of debris. | exhaust (see page 5). Allow air to feed with debris. |

|

|

|

Abnormal vibration. | Loose or out of balance impeller or loose engine. | Check impeller and replace if required. Check |

|

| Engine. |

|

|

|

Engine will not start. | Out of gasoline. Bad or old gasoline. Spark Plug wire | Check gasoline. Connect spark plug wire. Clean or |

| disconnected. Dirty air cleaner.Safety Interlock engaged. | replace air cleaner. Or contact a qualified service |

|

| person. Quick Disconnect not fully engaged. |

|

|

|

Engine is locked, will not | Engine problem. | Contact an engine servicing dealer for engine |

pull over. |

| problems. |

|

|

|

20.1 | Engine Service and Warranty | ||

Contact your nearest engine manufacturer's autho- | |||

| |||

|

| rized servicing dealer. | |

19 | Serial Plate | Record your machine model, serial number | |

and | |||

|

| ||

| 1803 S. Jefferson | |

| P.O. Box 308 | |

| Lee's Summit, | |

| MO | 64063 / USA |

R | Tel (816) | |

| ||

| Fax (816) | |

104 dB |

| Model |

|

|

| Serial No. |

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Unit(Weight) |

|

|

|

| Engine Power |

|

|

| ||||

|

|

|

| lbs. |

|

| kg |

|

|

| kW |

|

| rpm | |

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

WARRANTY PROCEDURE

20Please fill in the WARRANTY CARD and send the upper part to Billy Goat. The WARRANTY terms are stated on the lower part which remains with the user. Whenever a Billy Goat Machine is faulty due to a defect in material and / or workmanship, the owner should make a warranty claim as follows:

The Machine should be taken to the dealer from whom it was purchased or to an authorized Billy Goat dealer.

The owner should present the remaining half of the Warranty Registration Card, or, if this is not available, the invoice or receipt.

The Warranty Claim will be filled in by the authorized Billy Goat Dealer, who will send it with the faulty part to Billy Goat headquarters.

The Quality / Service department at Billy Goat headquarters will study the claim and parts and will notify their conclusions.

The decision by the Quality / Service department at Billy Goat headquarters to approve or reject a Warranty claim is final and binding.

Note: To process a Warranty Claim, it is necessary to quote the Model & Serial number who are printed on the Billy Goat Serial Plate.

Purchase | Purchased | ||

Date |

| from |

|

|

| ||

R

BILLY GOAT INDUSTRIES INC.

1803 S JEFFERSON LEE'S SUMMIT, MO 64082 / USA PHONE:

Part No. 890564

Page 8 of 8 | Form No. F022502A |