QB1104H, QB1004, QB884H specifications

The Billy Goat QB884H, QB1004, and QB1104H are professional-grade walk-behind leaf blowers designed for optimal performance, efficiency, and ease of use. These models stand out in the market due to their rugged construction and advanced technological features, making them ideal for both residential and commercial applications.The QB884H is equipped with a powerful Honda engine, delivering impressive performance and reliability. Its 8-blade impeller significantly increases air velocity, allowing for efficient removal of leaves and debris. The lightweight design enhances maneuverability, making it easy to operate for extended periods. It also features a unique ergonomic handle that reduces operator fatigue and improves control during use.

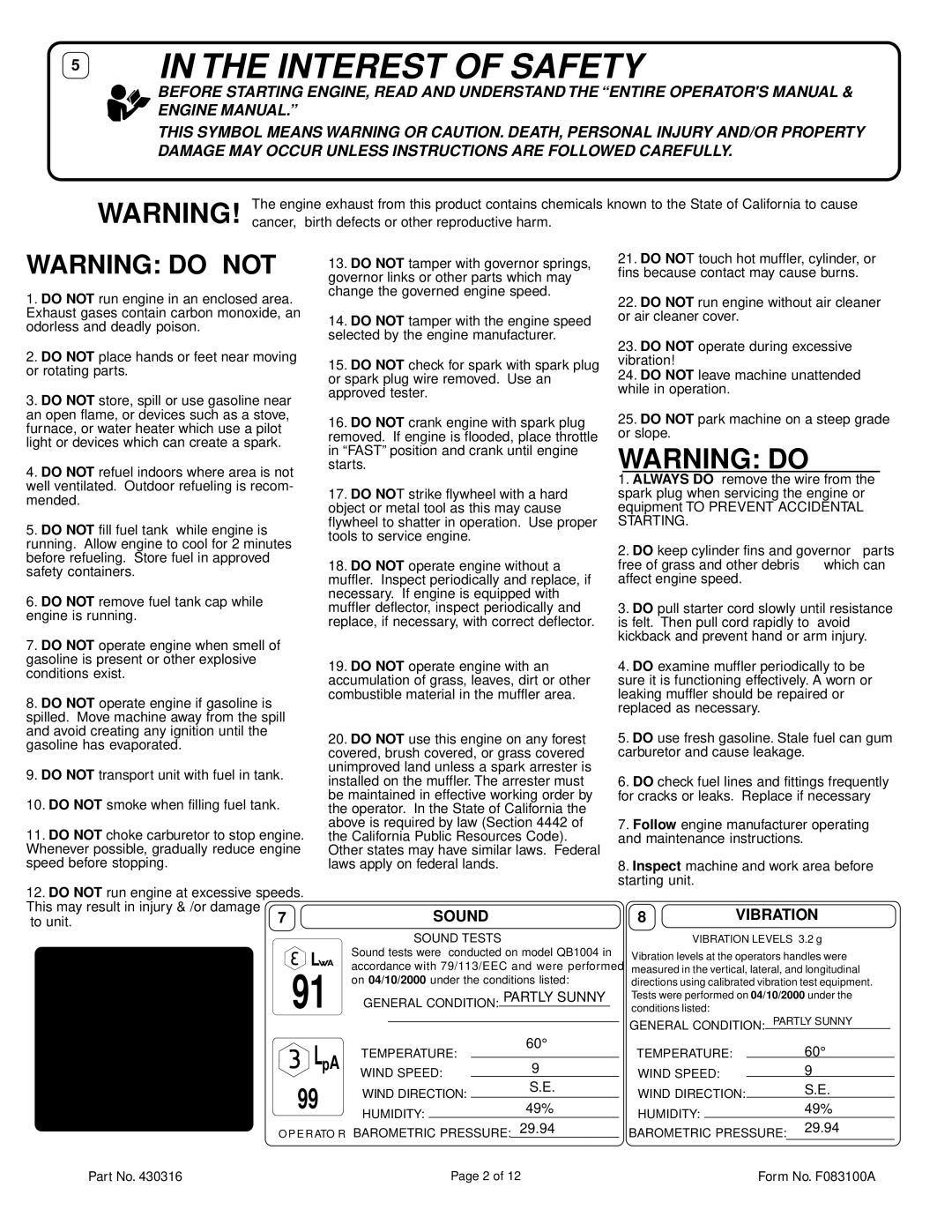

Next in line, the QB1004 offers a step up in power with its robust engine, providing superior airflow and improved clearing capacity. This model integrates an innovative debris management system, which reduces clogging and enhances overall efficiency. The unit’s adjustable airflow speed allows users to customize performance depending on the size and density of the debris, making it an excellent choice for various tasks. Additionally, its quick-release nozzle design makes switching between tasks seamless.

The QB1104H is the heavy-duty option in this lineup, boasting the most powerful engine among the three. It is engineered for commercial use, capable of tackling the toughest jobs. The advanced overhead valve design is specifically calibrated for maximum torque at lower RPM, ensuring higher efficiency and lower fuel consumption. The QB1104H includes an easy-start system for smoother operation and reduces the effort needed to power up the machine.

All three models feature a durable, weather-resistant construction that ensures longevity even in challenging conditions. Maintenance is straightforward, with accessible components allowing easy serviceability. The highlighted safety features include an automatic engine shut-off that activates when the handle is released, ensuring operator safety.

In summary, the Billy Goat QB884H, QB1004, and QB1104H deliver exceptional performance with innovations that enhance usability, making them valuable tools for any landscaping professional or property owner. Their combination of power, efficiency, and ergonomic design sets them apart, demonstrating why they are highly regarded in the industry. Whether tackling residential lawns or large commercial properties, these models are equipped to meet diverse landscaping needs.