SV50H, SV50 specifications

The Billy Goat SV50 and SV50H are outstanding additions to the realm of outdoor power equipment, delivering remarkable performance and reliability. These versatile blowers are especially designed for professionals, landscapers, and dedicated homeowners who require robust tools for efficient yard maintenance.One of the standout features of the SV50 series is its powerful engine. The SV50 is equipped with a reliable 50cc engine, while the SV50H incorporates a high-performance Honda engine, known for its exceptional durability and low emissions. This results in a performance-driven approach that ensures optimal airflow and handling for various tasks. With airflow ratings reaching up to 780 CFM (cubic feet per minute), these models are capable of moving heavy debris, leaves, and grass with ease, making yard clean-up and maintenance faster and more efficient.

A notable characteristic of the SV50 and SV50H is their lightweight design, which provides ease of maneuverability without sacrificing power. Weighing in at only 50 pounds, these blowers reduce user fatigue during extended operation. The ergonomic handle is designed for comfort, allowing for prolonged use without discomfort.

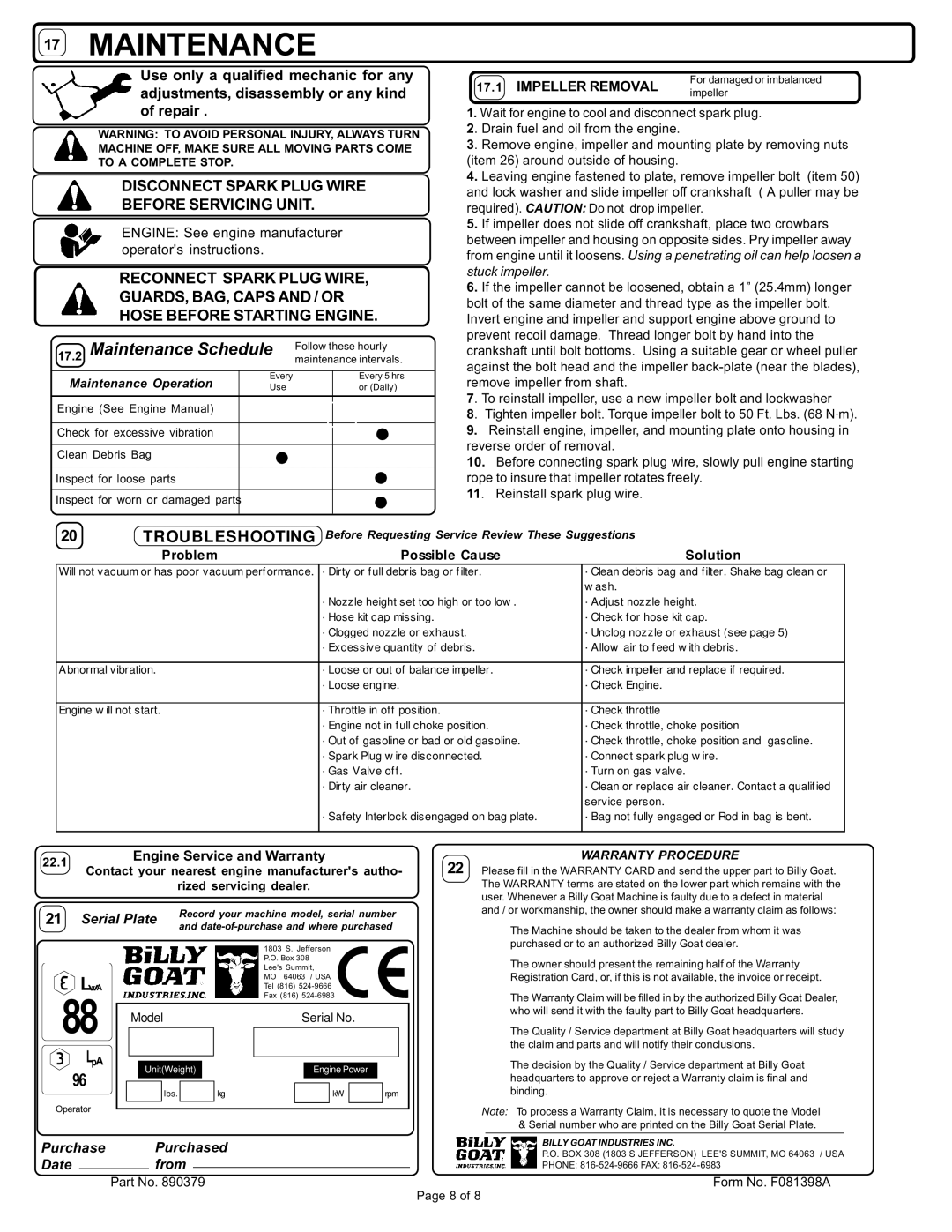

In addition to their power and comfort, both models are constructed with durability in mind. The heavy-duty materials used in their construction ensure they can withstand the rigors of commercial use, making them ideal for daily professional tasks. Furthermore, the SV50 series incorporates simple, tool-less access for easy maintenance, which is crucial for maintaining efficiency and longevity.

Another important aspect of the Billy Goat SV50 and SV50H is their fuel efficiency. Thanks to advanced engineering and design, these blowers boast extended runtime, allowing for longer working periods before refueling. This feature is particularly beneficial for outdoor professionals who need to maximize productivity on the job site.

Safety features are also prioritized in the SV50 series, including a simple throttle control for precise handling and reduced operator fatigue. The compact design allows for storage in smaller spaces without compromising on power and efficiency.

In conclusion, the Billy Goat SV50 and SV50H are powerful and reliable blowers that deliver high performance for both professionals and homeowners. Their combination of an efficient engine, lightweight design, ease of maintenance, fuel efficiency, and safety features positions them as valuable tools in yard care and landscaping. Whether tackling leaves in the fall or maintaining a pristine outdoor space year-round, the SV50 series meets the demands of any outdoor task with excellence.