16OPERATION continued

16.6 | PROPULSION | 16.4 | HANDLING & TRANSPORTING: |

This vacuum is

GROUND SPEED can be varied by applying slight downward pressure to handle during operation (to allow drive wheels partial slippage) or by changing the engine rpm.

For improved control in confined areas, this machine can be freewheel pushed forward or backward by releasing the operator's bail and pushing machine.

Bail Up

EngagesHandle

Drive

Using two people to lift machine is recommended. Lift holding the handle and front of nozzle. Secure in place during transport.

16.5STORAGE

![]() Never store engine indoors or in enclosed poorly ventilated areas with fuel in tank, where fuel fumes may reach an open flame, spark or pilot light, as on a furnace, water heater, clothes dryer or other gas appliance.

Never store engine indoors or in enclosed poorly ventilated areas with fuel in tank, where fuel fumes may reach an open flame, spark or pilot light, as on a furnace, water heater, clothes dryer or other gas appliance.

If engine is to be unused for 30 days or more, prepare as follows:

![]() Be sure engine is cool. Do not smoke. Remove all gasoline from carburetor and fuel tank to prevent gum deposits from forming on these parts and causing possible malfunction of engine. Drain fuel outdoors, into an approved container, away from open flame. Run engine until fuel tank is empty and engine runs out of gasoline.

Be sure engine is cool. Do not smoke. Remove all gasoline from carburetor and fuel tank to prevent gum deposits from forming on these parts and causing possible malfunction of engine. Drain fuel outdoors, into an approved container, away from open flame. Run engine until fuel tank is empty and engine runs out of gasoline.

Bail Down

Disengages

Drive

Bail

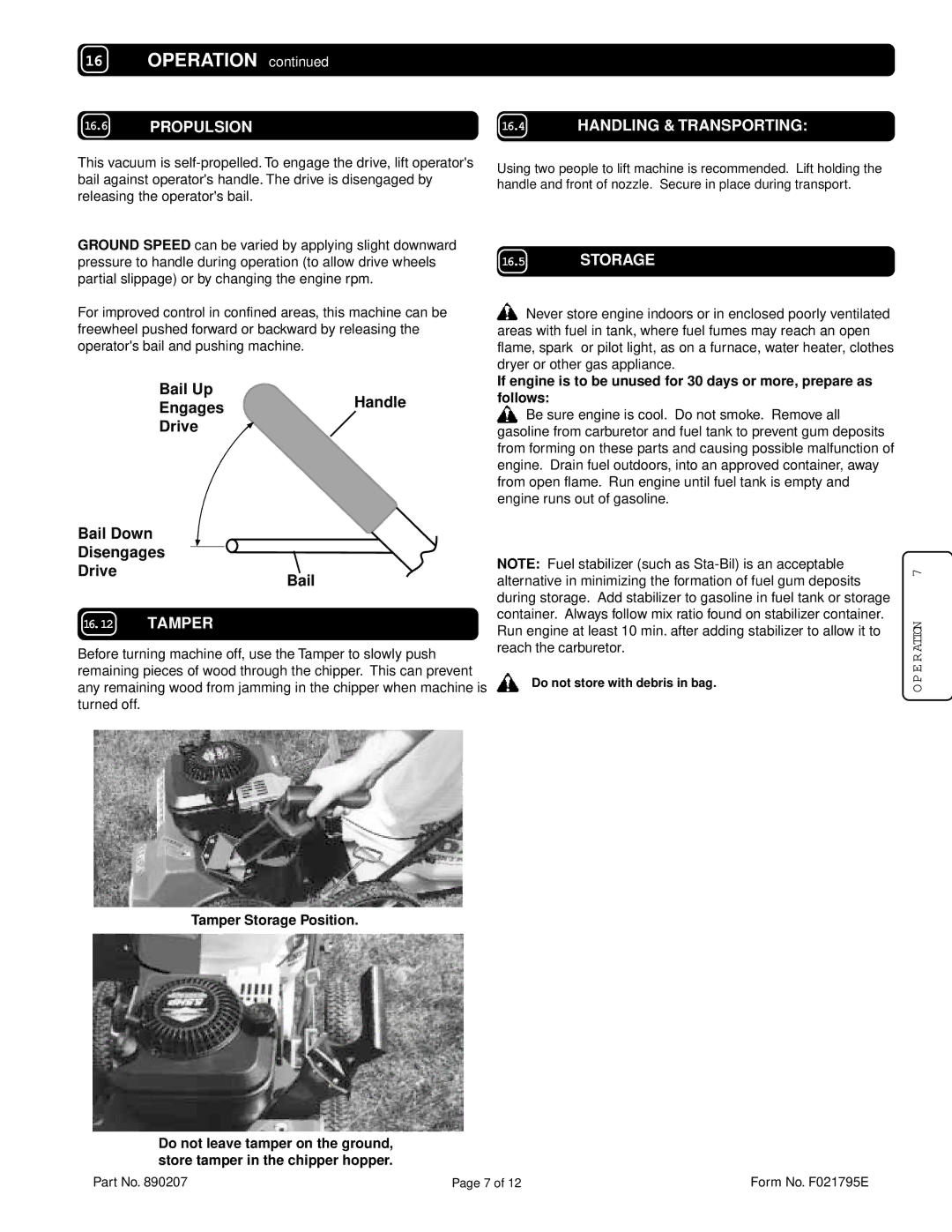

16.12TAMPER

Before turning machine off, use the Tamper to slowly push remaining pieces of wood through the chipper. This can prevent any remaining wood from jamming in the chipper when machine is turned off.

Tamper Storage Position.

NOTE: Fuel stabilizer (such as

Do not store with debris in bag.

O P E R ATION 7

Do not leave tamper on the ground, store tamper in the chipper hopper.

Part No. 890207 | Page 7 of 12 | Form No. F021795E |