D ![]()

C

E

Fig. 22

3.The table can be tilted right or left by pulling out and removing table alignment pin (C) Fig. 22. NOTE: If pin (C) is difficult to remove, turn nut (E) clockwise to pull pin out of casting.

4.Fig. 23, illustrates the table alignment pin (C) removed. Loosen table locking bolt (D), tilt table to the desired angle and tighten bolt (D). When returning table to the level position, replace table alignment pin (C). This will position the table surface at 90 degrees to the spindle.

5.A tilt scale (E) Fig. 24, is provided on the table bracket casting to indicate the degree of tilt. A witness line and zero mark (F) are also provided on the table to line up with the scale (E).

SPINDLE SPEEDS

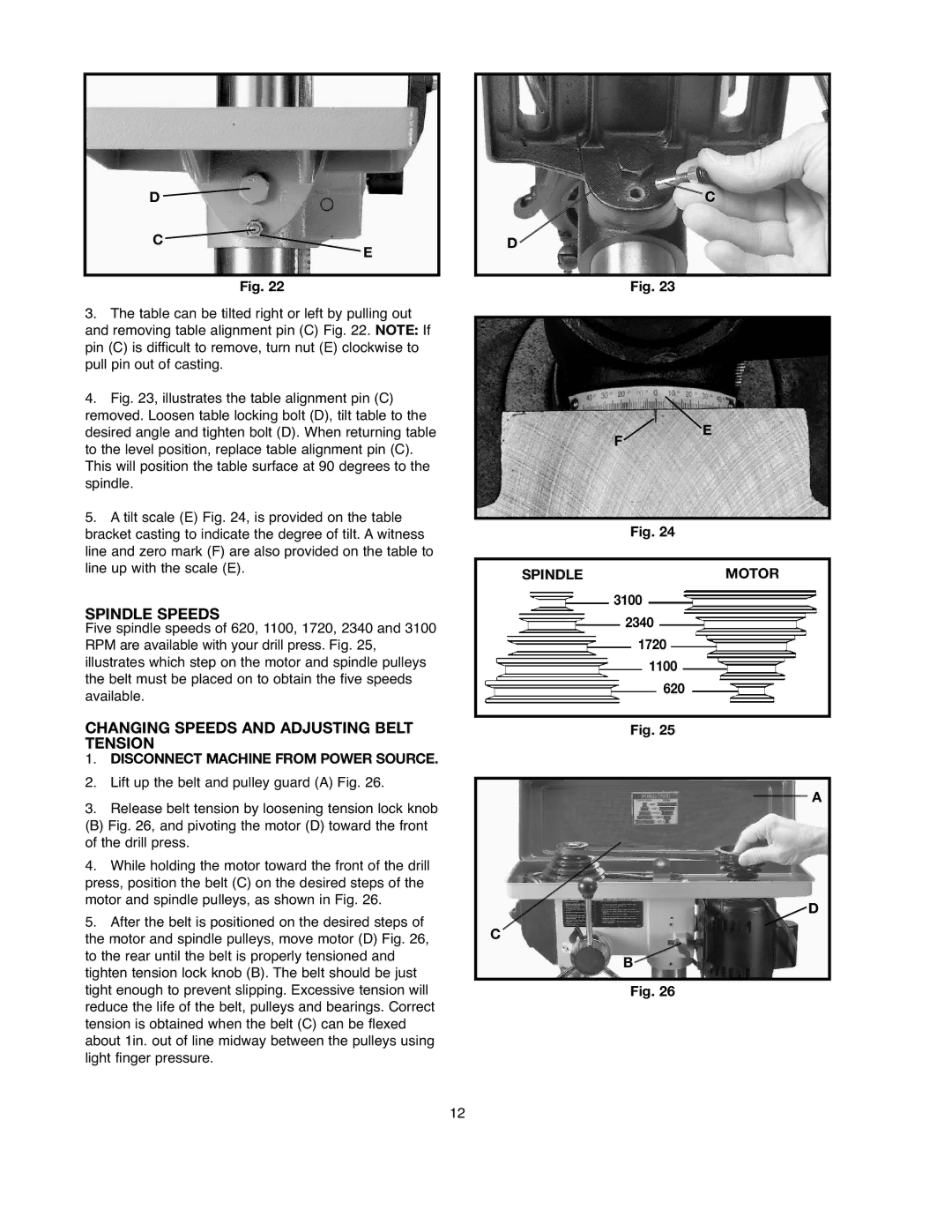

Five spindle speeds of 620, 1100, 1720, 2340 and 3100 RPM are available with your drill press. Fig. 25, illustrates which step on the motor and spindle pulleys the belt must be placed on to obtain the five speeds available.

CHANGING SPEEDS AND ADJUSTING BELT TENSION

1.DISCONNECT MACHINE FROM POWER SOURCE.

2.Lift up the belt and pulley guard (A) Fig. 26.

3.Release belt tension by loosening tension lock knob

(B) Fig. 26, and pivoting the motor (D) toward the front of the drill press.

4.While holding the motor toward the front of the drill press, position the belt (C) on the desired steps of the motor and spindle pulleys, as shown in Fig. 26.

5.After the belt is positioned on the desired steps of the motor and spindle pulleys, move motor (D) Fig. 26, to the rear until the belt is properly tensioned and tighten tension lock knob (B). The belt should be just tight enough to prevent slipping. Excessive tension will reduce the life of the belt, pulleys and bearings. Correct tension is obtained when the belt (C) can be flexed about 1in. out of line midway between the pulleys using light finger pressure.

C

D

Fig. 23

E

F

Fig. 24

SPINDLEMOTOR

3100

2340

1720

1100

620

Fig. 25

A

![]() D

D

C

B![]()

Fig. 26

12