630669-00,BT1000 manual 2/15/05 8:11 AM Page 14

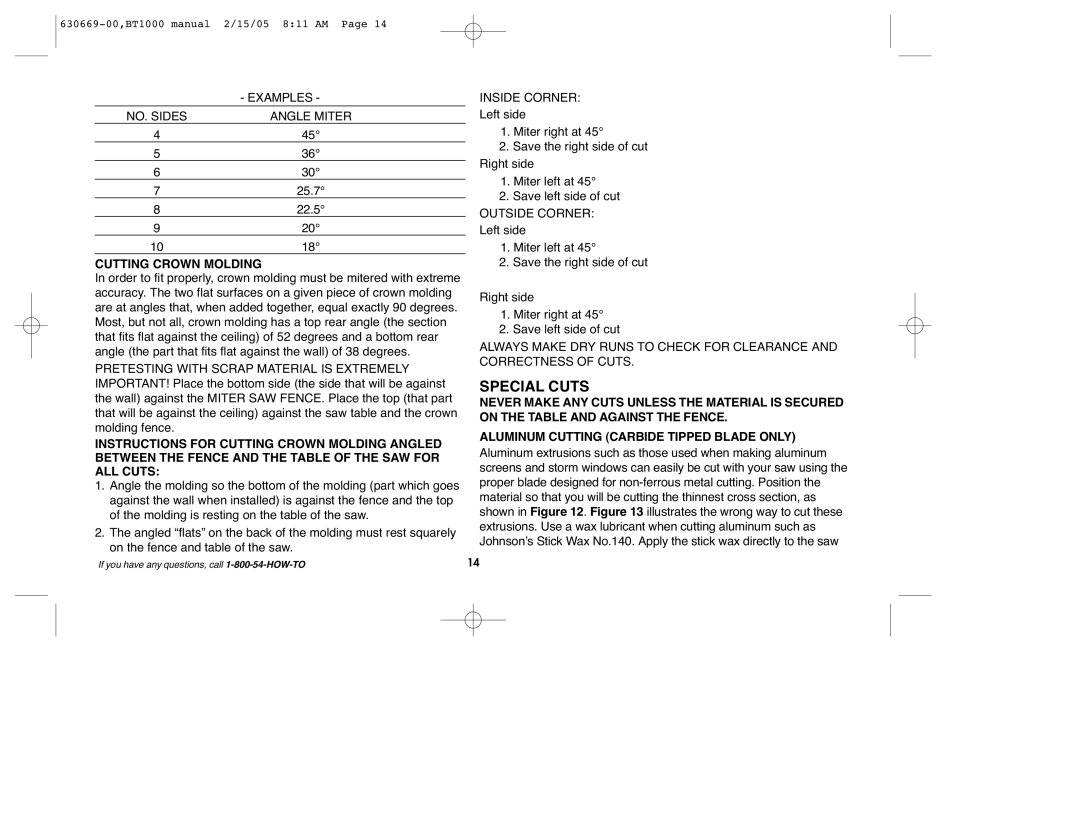

- EXAMPLES -

NO. SIDES | ANGLE MITER |

445°

536°

630°

725.7°

822.5°

920°

1018°

CUTTING CROWN MOLDING

In order to fit properly, crown molding must be mitered with extreme accuracy. The two flat surfaces on a given piece of crown molding are at angles that, when added together, equal exactly 90 degrees. Most, but not all, crown molding has a top rear angle (the section that fits flat against the ceiling) of 52 degrees and a bottom rear angle (the part that fits flat against the wall) of 38 degrees.

PRETESTING WITH SCRAP MATERIAL IS EXTREMELY IMPORTANT! Place the bottom side (the side that will be against the wall) against the MITER SAW FENCE. Place the top (that part that will be against the ceiling) against the saw table and the crown molding fence.

INSTRUCTIONS FOR CUTTING CROWN MOLDING ANGLED BETWEEN THE FENCE AND THE TABLE OF THE SAW FOR ALL CUTS:

1.Angle the molding so the bottom of the molding (part which goes against the wall when installed) is against the fence and the top of the molding is resting on the table of the saw.

2.The angled “flats” on the back of the molding must rest squarely on the fence and table of the saw.

If you have any questions, call

INSIDE CORNER:

Left side

1.Miter right at 45°

2.Save the right side of cut

Right side

1.Miter left at 45°

2.Save left side of cut

OUTSIDE CORNER:

Left side

1.Miter left at 45°

2.Save the right side of cut

Right side

1.Miter right at 45°

2.Save left side of cut

ALWAYS MAKE DRY RUNS TO CHECK FOR CLEARANCE AND CORRECTNESS OF CUTS.

SPECIAL CUTS

NEVER MAKE ANY CUTS UNLESS THE MATERIAL IS SECURED ON THE TABLE AND AGAINST THE FENCE.

ALUMINUM CUTTING (CARBIDE TIPPED BLADE ONLY)

Aluminum extrusions such as those used when making aluminum screens and storm windows can easily be cut with your saw using the proper blade designed for

14