CS1010, CS1020 specifications

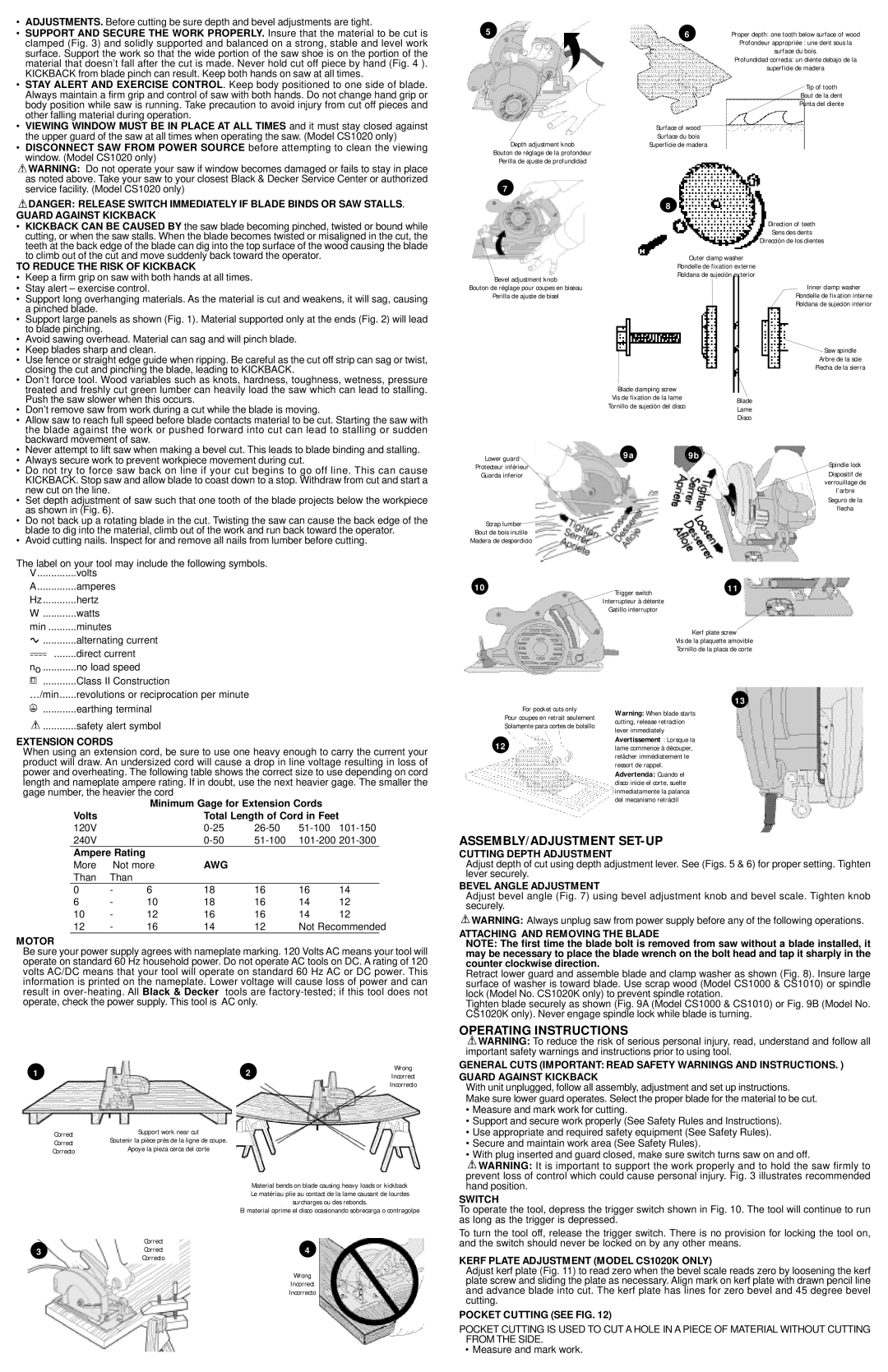

The Black & Decker CS1010 and CS1020 are two innovative models in the company's line of electric chainsaws, representing a perfect blend of performance, ease of use, and reliability. Both models are designed for homeowners and DIY enthusiasts who crave power and control for their cutting tasks, whether it's trimming branches, cutting firewood, or tackling larger yard work projects.Starting with the CS1010, this model features a robust 10-amp motor that provides ample power for various cutting needs. The 10-inch bar and chain allow for precise cuts and maneuverability, making it perfect for light to medium-duty tasks. The CS1010 comes with a tool-free chain tensioning system, enabling users to easily adjust the chain without the need for additional tools. This feature enhances convenience, especially during extended use, ensuring that the chain remains at optimal tension for efficient cutting performance.

On the other hand, the CS1020 boasts a slightly more powerful 12-amp motor, complemented by a longer 12-inch cutting bar. This added power and length make the CS1020 ideal for homeowners looking to tackle more substantial branches and logs with ease. Like the CS1010, it features a tool-free chain tensioning system that facilitates quick adjustments, allowing users to maintain their workflow without interruptions.

Both models prioritize safety with built-in safety features such as a chain brake that allows for immediate stopping of the chain to prevent accidents. The comfortable handle design provides a secure grip, enhancing user control during operation. The lightweight construction of both chainsaws makes them easy to handle and maneuver, reducing fatigue during prolonged use.

In terms of maintenance, both the CS1010 and CS1020 feature automatic oiling systems that lubricate the chain and bar during use. This ensures optimal performance and extends the life of the chain and bar, minimizing the time and effort needed for maintenance.

In conclusion, the Black & Decker CS1010 and CS1020 are excellent choices for light to medium cutting tasks. With their powerful motors, user-friendly features, and safety mechanisms, they effectively meet the needs of homeowners and DIY enthusiasts alike. Whether you choose the CS1010 for its compactness or the CS1020 for its enhanced cutting capabilities, either model promises reliable performance for your outdoor projects.