ENGLISH

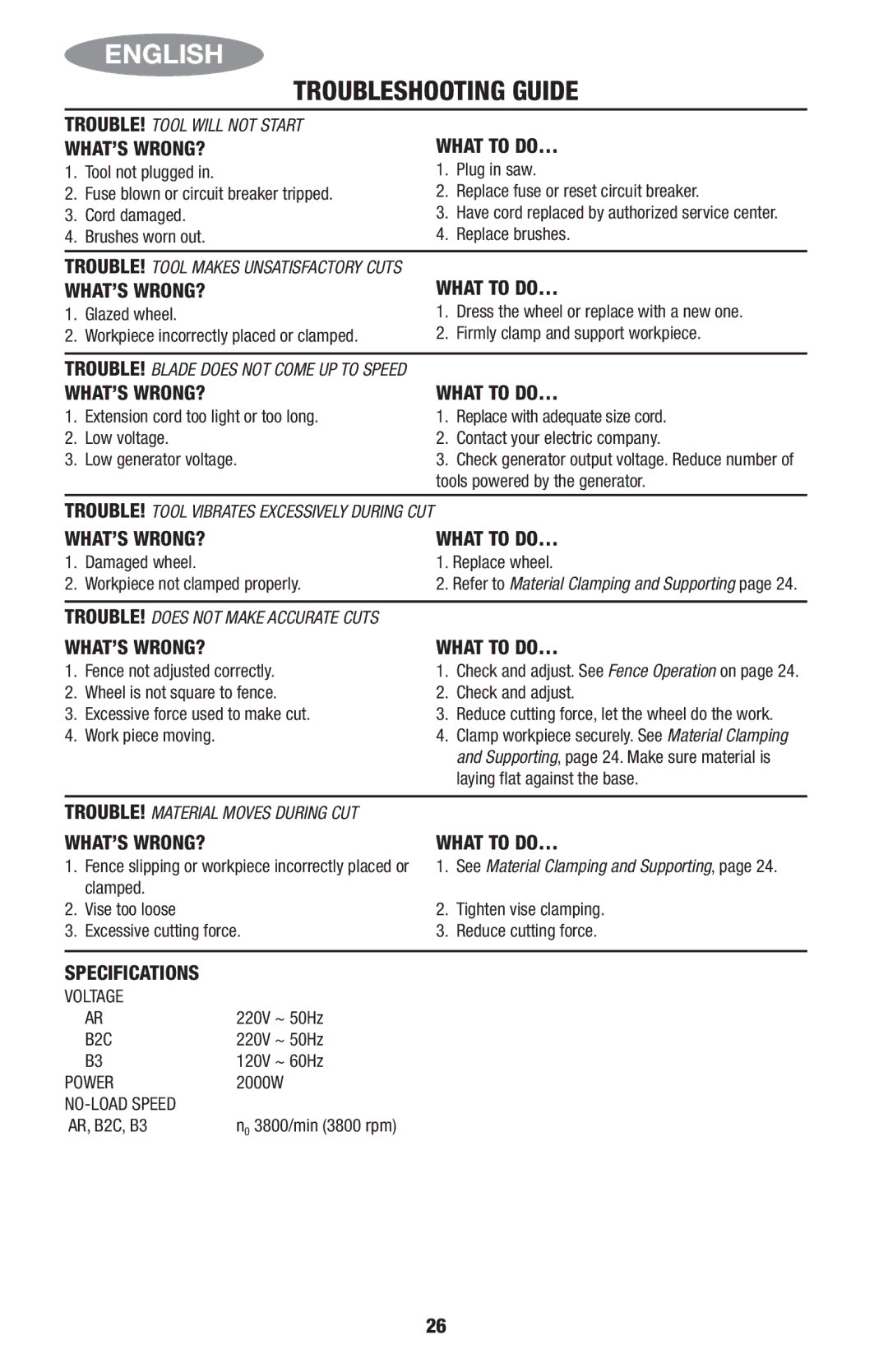

TROUBLESHOOTING GUIDE

TROUBLE! TOOL WILL NOT START | WHAT TO DO… | ||

WHAT’S WRONG? | |||

1. | Tool not plugged in. | 1. | Plug in saw. |

2. | Fuse blown or circuit breaker tripped. | 2. | Replace fuse or reset circuit breaker. |

3. | Cord damaged. | 3. | Have cord replaced by authorized service center. |

4. | Brushes worn out. | 4. | Replace brushes. |

|

|

| |

TROUBLE! TOOL MAKES UNSATISFACTORY CUTS | WHAT TO DO… | ||

WHAT’S WRONG? | |||

1. | Glazed wheel. | 1. | Dress the wheel or replace with a new one. |

2. | Workpiece incorrectly placed or clamped. | 2. | Firmly clamp and support workpiece. |

|

|

| |

TROUBLE! BLADE DOES NOT COME UP TO SPEED |

|

| |

WHAT’S WRONG? | WHAT TO DO… | ||

1. | Extension cord too light or too long. | 1. | Replace with adequate size cord. |

2. | Low voltage. | 2. | Contact your electric company. |

3. | Low generator voltage. | 3. | Check generator output voltage. Reduce number of |

|

| tools powered by the generator. | |

|

| ||

TROUBLE! TOOL VIBRATES EXCESSIVELY DURING CUT |

| ||

WHAT’S WRONG? | WHAT TO DO… | ||

1. | Damaged wheel. | 1. | Replace wheel. |

2. | Workpiece not clamped properly. | 2. | Refer to Material Clamping and Supporting page 24. |

|

|

| |

TROUBLE! DOES NOT MAKE ACCURATE CUTS |

|

| |

WHAT’S WRONG? | WHAT TO DO… | ||

1. | Fence not adjusted correctly. | 1. | Check and adjust. See Fence Operation on page 24. |

2. | Wheel is not square to fence. | 2. | Check and adjust. |

3. | Excessive force used to make cut. | 3. | Reduce cutting force, let the wheel do the work. |

4. | Work piece moving. | 4. | Clamp workpiece securely. See Material Clamping |

|

|

| and Supporting, page 24. Make sure material is |

|

|

| laying flat against the base. |

TROUBLE! MATERIAL MOVES DURING CUT

WHAT’S WRONG?

1.Fence slipping or workpiece incorrectly placed or clamped.

2.Vise too loose

3.Excessive cutting force.

WHAT TO DO…

1.See Material Clamping and Supporting, page 24.

2.Tighten vise clamping.

3.Reduce cutting force.

SPECIFICATIONS

VOLTAGE |

|

AR | 220V ~ 50Hz |

B2C | 220V ~ 50Hz |

B3 | 120V ~ 60Hz |

POWER | 2000W |

|

|

AR, B2C, B3 | n0 3800/min (3800 rpm) |

26