ENGLISH

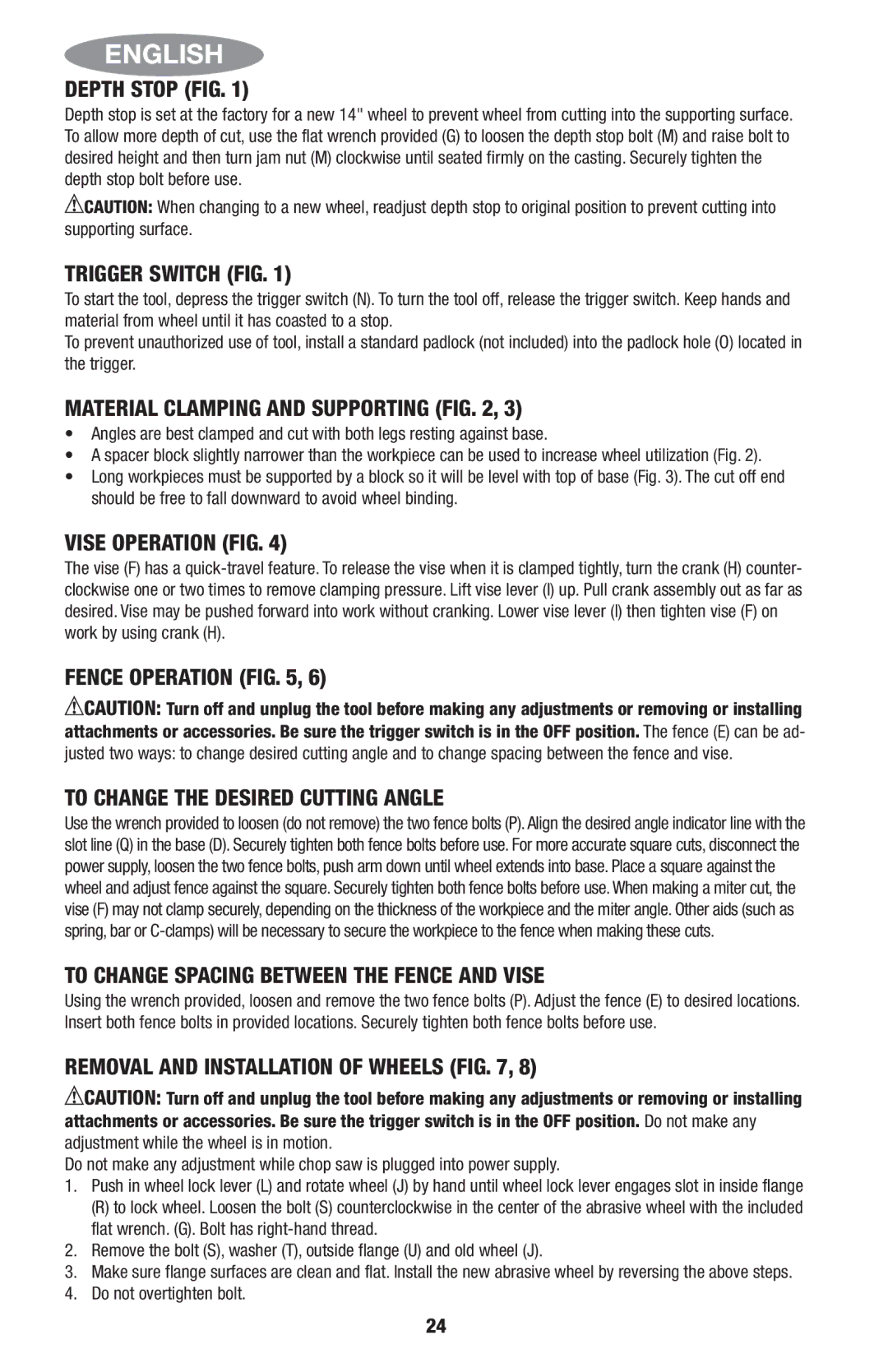

DEPTH STOP (FIG. 1)

Depth stop is set at the factory for a new 14" wheel to prevent wheel from cutting into the supporting surface. To allow more depth of cut, use the flat wrench provided (G) to loosen the depth stop bolt (M) and raise bolt to desired height and then turn jam nut (M) clockwise until seated firmly on the casting. Securely tighten the depth stop bolt before use.

![]() CAUTION: When changing to a new wheel, readjust depth stop to original position to prevent cutting into supporting surface.

CAUTION: When changing to a new wheel, readjust depth stop to original position to prevent cutting into supporting surface.

TRIGGER SWITCH (FIG. 1)

To start the tool, depress the trigger switch (N). To turn the tool off, release the trigger switch. Keep hands and material from wheel until it has coasted to a stop.

To prevent unauthorized use of tool, install a standard padlock (not included) into the padlock hole (O) located in the trigger.

MATERIAL CLAMPING AND SUPPORTING (FIG. 2, 3)

•Angles are best clamped and cut with both legs resting against base.

•A spacer block slightly narrower than the workpiece can be used to increase wheel utilization (Fig. 2).

• Long workpieces must be supported by a block so it will be level with top of base (Fig. 3). The cut off end should be free to fall downward to avoid wheel binding.

VISE OPERATION (FIG. 4)

The vise (F) has a

FENCE OPERATION (FIG. 5, 6)

![]() CAUTION: Turn off and unplug the tool before making any adjustments or removing or installing attachments or accessories. Be sure the trigger switch is in the OFF position. The fence (E) can be ad- justed two ways: to change desired cutting angle and to change spacing between the fence and vise.

CAUTION: Turn off and unplug the tool before making any adjustments or removing or installing attachments or accessories. Be sure the trigger switch is in the OFF position. The fence (E) can be ad- justed two ways: to change desired cutting angle and to change spacing between the fence and vise.

TO CHANGE THE DESIRED CUTTING ANGLE

Use the wrench provided to loosen (do not remove) the two fence bolts (P). Align the desired angle indicator line with the slot line (Q) in the base (D). Securely tighten both fence bolts before use. For more accurate square cuts, disconnect the power supply, loosen the two fence bolts, push arm down until wheel extends into base. Place a square against the wheel and adjust fence against the square. Securely tighten both fence bolts before use. When making a miter cut, the vise (F) may not clamp securely, depending on the thickness of the workpiece and the miter angle. Other aids (such as spring, bar or

TO CHANGE SPACING BETWEEN THE FENCE AND VISE

Using the wrench provided, loosen and remove the two fence bolts (P). Adjust the fence (E) to desired locations. Insert both fence bolts in provided locations. Securely tighten both fence bolts before use.

REMOVAL AND INSTALLATION OF WHEELS (FIG. 7, 8)

![]() CAUTION: Turn off and unplug the tool before making any adjustments or removing or installing attachments or accessories. Be sure the trigger switch is in the OFF position. Do not make any adjustment while the wheel is in motion.

CAUTION: Turn off and unplug the tool before making any adjustments or removing or installing attachments or accessories. Be sure the trigger switch is in the OFF position. Do not make any adjustment while the wheel is in motion.

Do not make any adjustment while chop saw is plugged into power supply.

1.Push in wheel lock lever (L) and rotate wheel (J) by hand until wheel lock lever engages slot in inside flange

(R) to lock wheel. Loosen the bolt (S) counterclockwise in the center of the abrasive wheel with the included flat wrench. (G). Bolt has

2.Remove the bolt (S), washer (T), outside flange (U) and old wheel (J).

3.Make sure flange surfaces are clean and flat. Install the new abrasive wheel by reversing the above steps.

4.Do not overtighten bolt.

24