DW900,DW901/383609 bc 5/8/02 2:59 PM Page 4

English

from left to right. The center position of the bar

SWITCH

To turn the tool on, squeeze the trigger switch. When the tool reaches its set torque level, the spindle will stop and the LED light on the back of the tool will illuminate. Do not continually squeeze and release the trigger when driving a joint; let the tool stop automatically.

Adjusting Torque Level

![]() WARNING: Remove the battery before making any adjustments.

WARNING: Remove the battery before making any adjustments.

1)Insert a 1/4" hex key into the spindle and turn it for one rotation. You may hear a click, indicating the clutch is coupled.

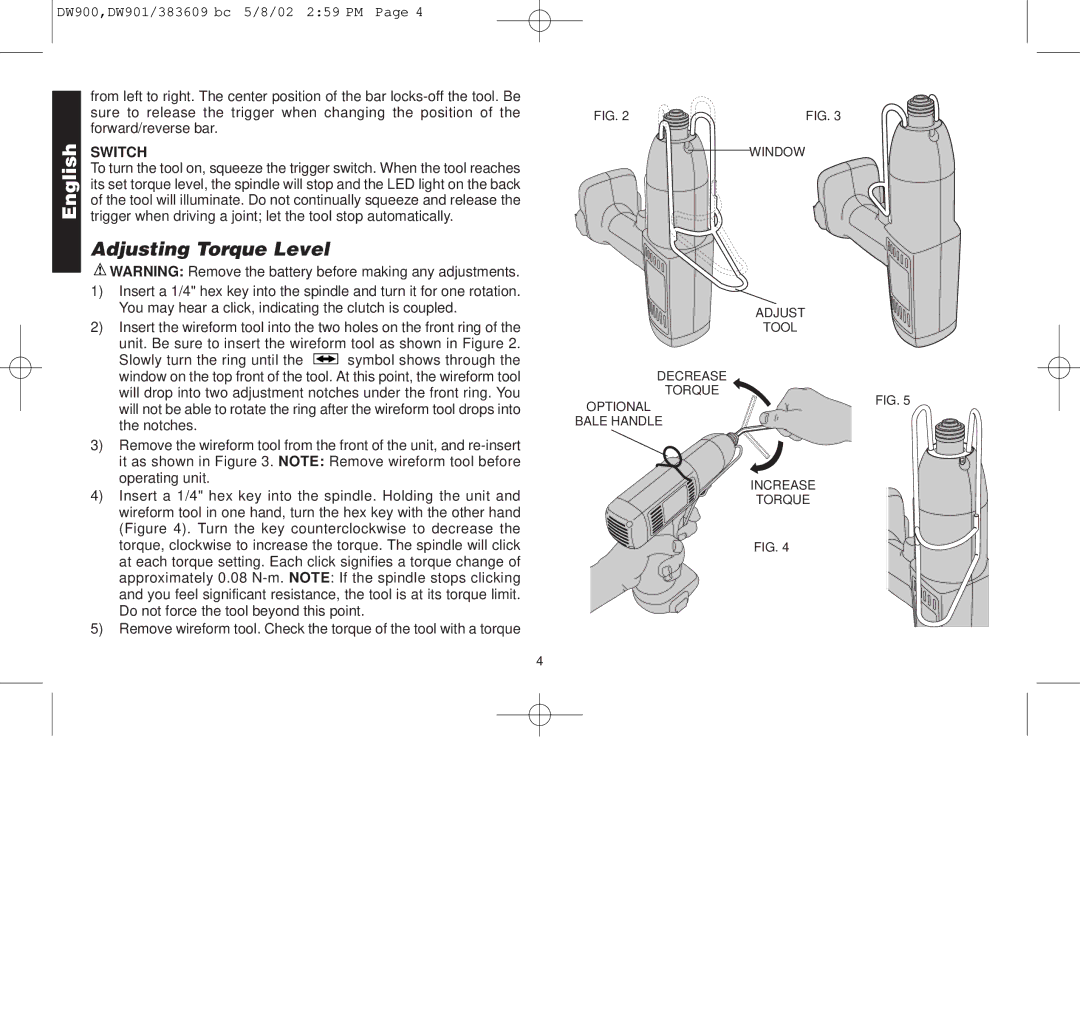

2)Insert the wireform tool into the two holes on the front ring of the unit. Be sure to insert the wireform tool as shown in Figure 2.

Slowly turn the ring until the ![]()

![]()

![]()

![]() symbol shows through the window on the top front of the tool. At this point, the wireform tool will drop into two adjustment notches under the front ring. You will not be able to rotate the ring after the wireform tool drops into the notches.

symbol shows through the window on the top front of the tool. At this point, the wireform tool will drop into two adjustment notches under the front ring. You will not be able to rotate the ring after the wireform tool drops into the notches.

3)Remove the wireform tool from the front of the unit, and

4)Insert a 1/4" hex key into the spindle. Holding the unit and wireform tool in one hand, turn the hex key with the other hand (Figure 4). Turn the key counterclockwise to decrease the torque, clockwise to increase the torque. The spindle will click at each torque setting. Each click signifies a torque change of approximately 0.08

5)Remove wireform tool. Check the torque of the tool with a torque

4

FIG. 2 | FIG. 3 |

WINDOW

ADJUST

TOOL

DECREASE

TORQUE

OPTIONAL | FIG. 5 |

| |

BALE HANDLE |

|

INCREASE

TORQUE

FIG. 4