feet, use a work support at the rear of the saw to keep the workpiece from falling off the saw table.

3.If the ripped work is less than 6 inches wide, a push stick should always be used to complete the feed, as shown in Fig. 44. The push stick can easily be made from scrap material as explained in the section

“CONSTRUCTING A PUSH STICK.”

4.Ripping narrow pieces can be dangerous if not done carefully.

![]() WHEN THE PIECE IS TOO NARROW FOR A PUSH STICK TO BE EFFECTIVE

WHEN THE PIECE IS TOO NARROW FOR A PUSH STICK TO BE EFFECTIVE

-AND IF THE WORKPIECE IS SHORT ENOUGH - USE A PUSHBOARD. WHEN RIPPING MATERIAL UNDER 2 INCHES IN WIDTH, ORDINARY PUSH STICKS MAY INTERFERE WITH THE BLADE GUARD.

When using a pushboard, the width of the pushboard must be added to the width of the rip fence position setting. A flat pushboard can be constructed as shown in Fig. 46 and should be used as shown in Fig. 45. NOTE:

GUARD REMOVED FOR CLARITY. ALWAYS USE THE GUARD.

NOTE: Some special operations require the addition of an auxiliary wood facing to the fence, as explained in the section “USING AUXILIARY WOOD FACING ON THE RIP FENCE” and use of a push stick.

USING AUXILIARY WOOD FACING ON RIP FENCE

When performing special cutting operations – and that operation may cause the cutting implement to contact the fence – it is necessary to add a wood facing (A) Fig. 47, to one side of the rip fence as shown. The wood facing is attached to the fence with wood screws through holes drilled in the fence.

ACCESSORY DADO CUTTERHEAD

![]() THE MAXIMUM WIDTH DADO CUT FOR THIS SAW IS 1/2 INCH.

THE MAXIMUM WIDTH DADO CUT FOR THIS SAW IS 1/2 INCH.

![]() THE BLADE GUARD AND SPLITTER ASSEMBLY CANNOT BE USED WHEN DADOING. IT MUST BE REMOVED OR SWUNG TO THE REAR OF THE SAW.

THE BLADE GUARD AND SPLITTER ASSEMBLY CANNOT BE USED WHEN DADOING. IT MUST BE REMOVED OR SWUNG TO THE REAR OF THE SAW.

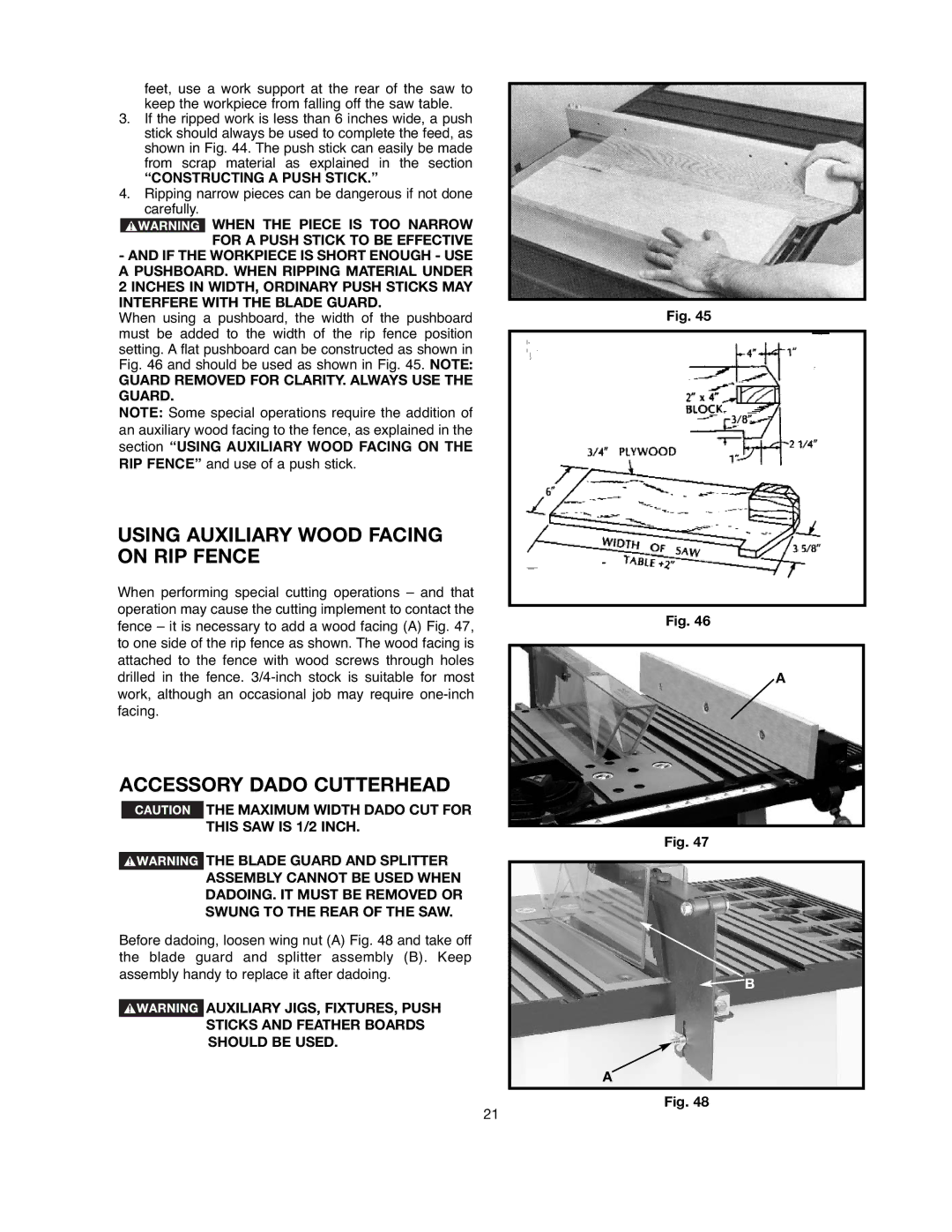

Before dadoing, loosen wing nut (A) Fig. 48 and take off the blade guard and splitter assembly (B). Keep assembly handy to replace it after dadoing.

![]() AUXILIARY JIGS, FIXTURES, PUSH STICKS AND FEATHER BOARDS SHOULD BE USED.

AUXILIARY JIGS, FIXTURES, PUSH STICKS AND FEATHER BOARDS SHOULD BE USED.

Fig. 45

Fig. 46

A

Fig. 47

![]() B

B

A

Fig. 48

21