Always ensure the unit is unplugged from the power supply when changing blades.

Always ensure the tooth protector is fitted when changing blades.

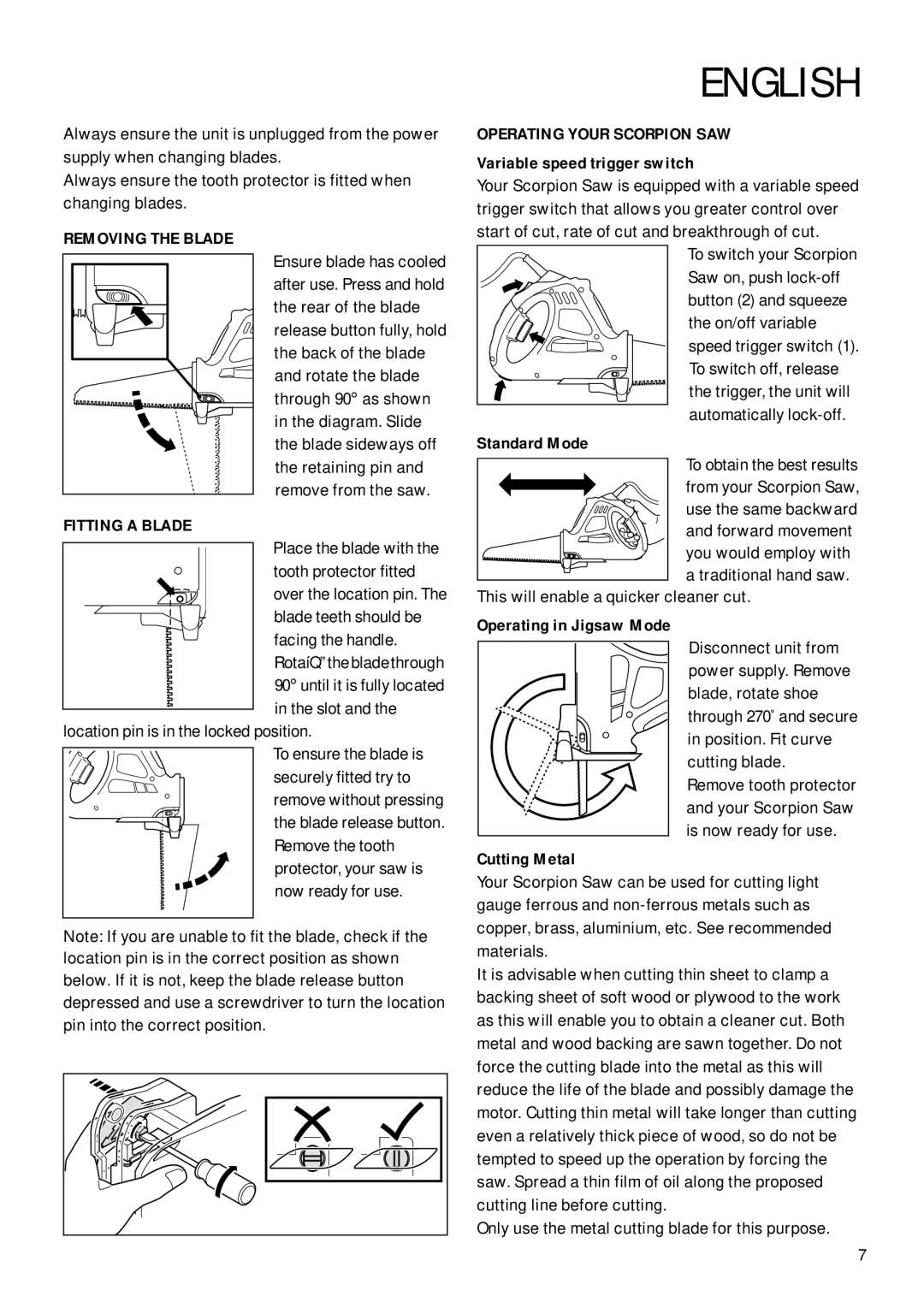

REMOVING THE BLADE

Ensure blade has cooled after use. Press and hold the rear of the blade release button fully, hold the back of the blade and rotate the blade through 90° as shown in the diagram. Slide the blade sideways off the retaining pin and remove from the saw.

FITTING A BLADE

Place the blade with the

tooth protector fitted

over the location pin. The blade teeth should be facing the handle. RotaíQ”the blade through 90° until it is fully located in the slot and the

location pin is in the locked position.

To ensure the blade is

securely fitted try to remove without pressing

the blade release button. Remove the tooth

protector, your saw is now ready for use.

Note: If you are unable to fit the blade, check if the location pin is in the correct position as shown below. If it is not, keep the blade release button depressed and use a screwdriver to turn the location pin into the correct position.

ENGLISH

OPERATING YOUR SCORPION SAW

Variable speed trigger switch

Your Scorpion Saw is equipped with a variable speed trigger switch that allows you greater control over start of cut, rate of cut and breakthrough of cut.

To switch your Scorpion Saw on, push

button (2) and squeeze

the on/off variable

speed trigger switch (1). To switch off, release the trigger, the unit will automatically

Standard Mode

To obtain the best results from your Scorpion Saw, use the same backward

and forward movement you would employ with a traditional hand saw.

This will enable a quicker cleaner cut.

Operating in Jigsaw Mode

Disconnect unit from power supply. Remove blade, rotate shoe through 270˚ and secure in position. Fit curve cutting blade.

Remove tooth protector and your Scorpion Saw is now ready for use.

Cutting Metal

Your Scorpion Saw can be used for cutting light gauge ferrous and

It is advisable when cutting thin sheet to clamp a backing sheet of soft wood or plywood to the work as this will enable you to obtain a cleaner cut. Both metal and wood backing are sawn together. Do not force the cutting blade into the metal as this will reduce the life of the blade and possibly damage the motor. Cutting thin metal will take longer than cutting even a relatively thick piece of wood, so do not be tempted to speed up the operation by forcing the saw. Spread a thin film of oil along the proposed cutting line before cutting.

Only use the metal cutting blade for this purpose.

7