MAINTENANCE

MAINTENANCE

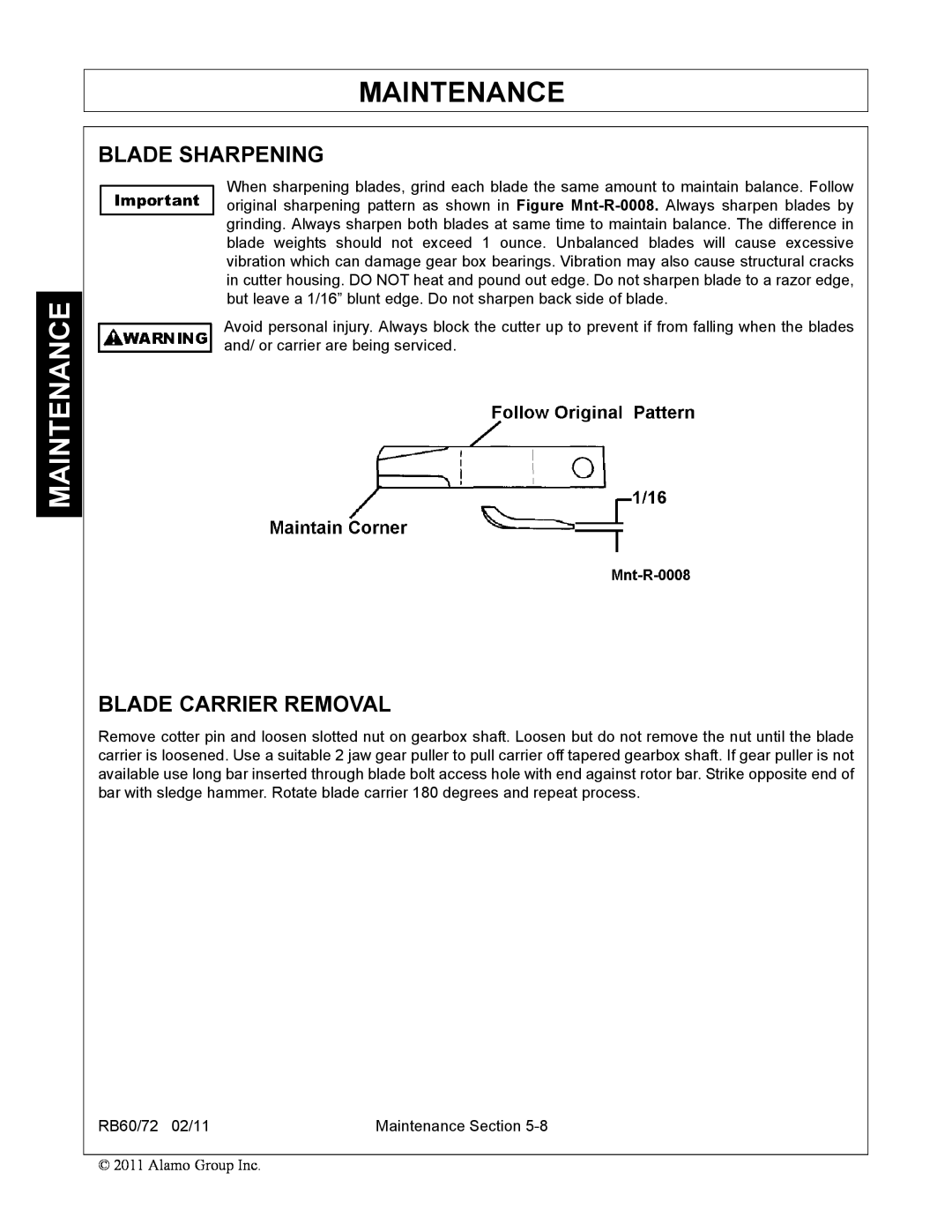

BLADE SHARPENING

When sharpening blades, grind each blade the same amount to maintain balance. Follow original sharpening pattern as shown in Figure

Avoid personal injury. Always block the cutter up to prevent if from falling when the blades and/ or carrier are being serviced.

BLADE CARRIER REMOVAL

Remove cotter pin and loosen slotted nut on gearbox shaft. Loosen but do not remove the nut until the blade carrier is loosened. Use a suitable 2 jaw gear puller to pull carrier off tapered gearbox shaft. If gear puller is not available use long bar inserted through blade bolt access hole with end against rotor bar. Strike opposite end of bar with sledge hammer. Rotate blade carrier 180 degrees and repeat process.

RB60/72 02/11 | Maintenance Section |

© 2011 Alamo Group Inc.