MAINTENANCE

BLADE CARRIER INSPECTION

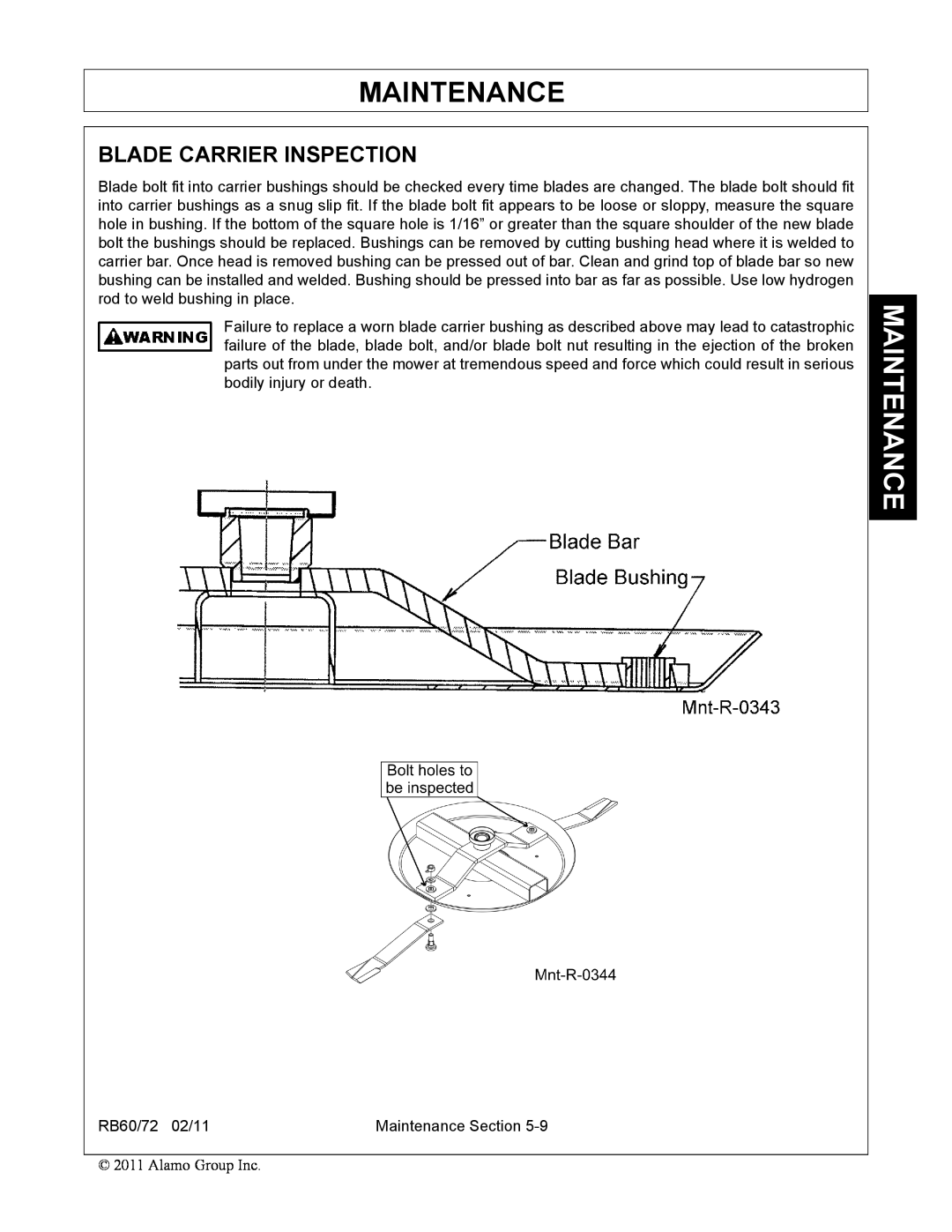

Blade bolt fit into carrier bushings should be checked every time blades are changed. The blade bolt should fit into carrier bushings as a snug slip fit. If the blade bolt fit appears to be loose or sloppy, measure the square hole in bushing. If the bottom of the square hole is 1/16” or greater than the square shoulder of the new blade bolt the bushings should be replaced. Bushings can be removed by cutting bushing head where it is welded to carrier bar. Once head is removed bushing can be pressed out of bar. Clean and grind top of blade bar so new bushing can be installed and welded. Bushing should be pressed into bar as far as possible. Use low hydrogen rod to weld bushing in place.

Failure to replace a worn blade carrier bushing as described above may lead to catastrophic failure of the blade, blade bolt, and/or blade bolt nut resulting in the ejection of the broken parts out from under the mower at tremendous speed and force which could result in serious bodily injury or death.

RB60/72 02/11 | Maintenance Section |

© 2011 Alamo Group Inc.

MAINTENANCE