Adjusting the quick release mechanism |

|

|

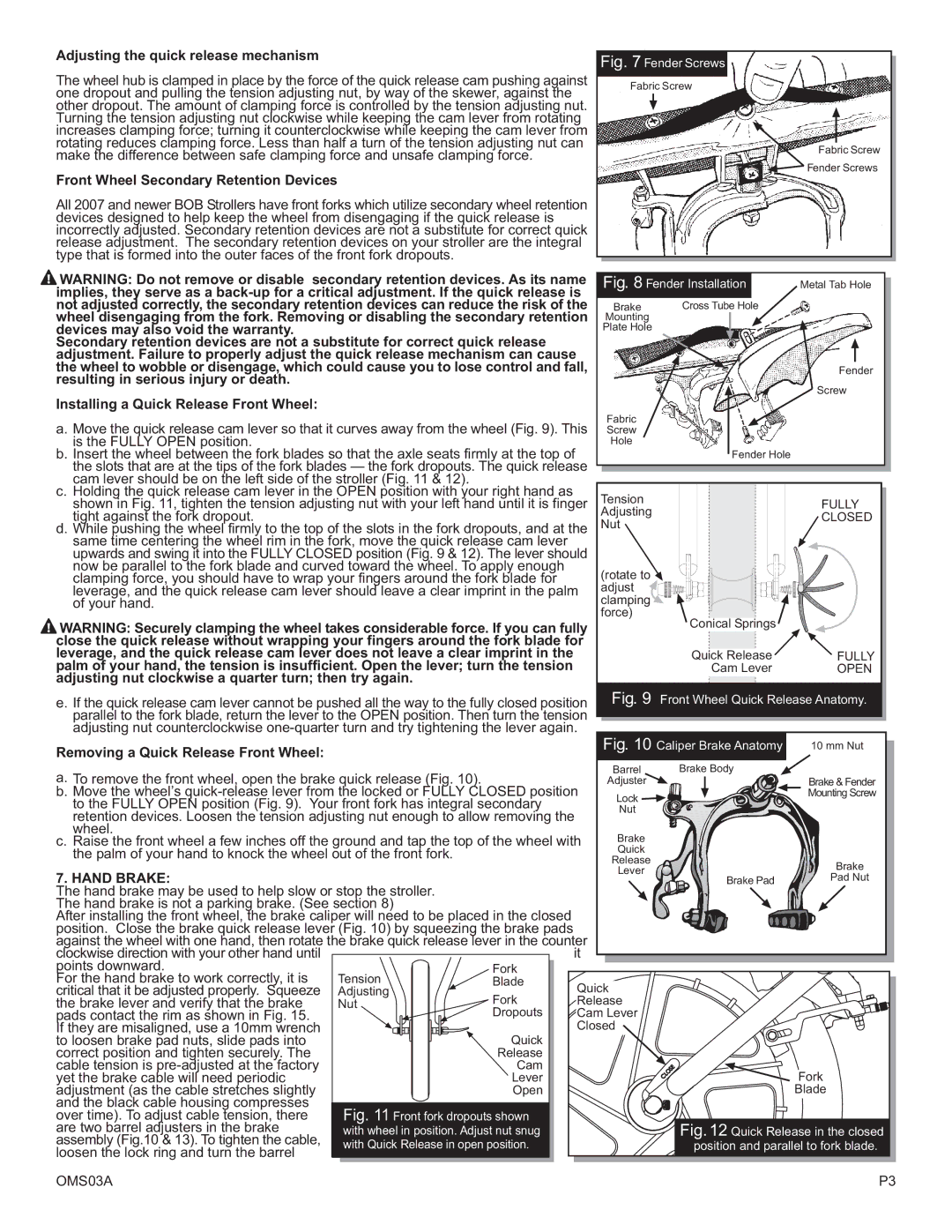

| Fig. 7 Fender Screws |

| |

|

|

|

|

| ||

The wheel hub is clamped in place by the force of the quick release cam pushing against | Fabric Screw |

| ||||

one dropout and pulling the tension adjusting nut, by way of the skewer, against the |

|

| ||||

|

|

|

| |||

other dropout. The amount of clamping force is controlled by the tension adjusting nut. |

|

|

| |||

Turning the tension adjusting nut clockwise while keeping the cam lever from rotating |

|

|

| |||

increases clamping force; turning it counterclockwise while keeping the cam lever from |

|

|

| |||

rotating reduces clamping force. Less than half a turn of the tension adjusting nut can |

|

| Fabric Screw | |||

make the difference between safe clamping force and unsafe clamping force. |

|

|

| |||

|

|

| Fender Screws | |||

Front Wheel Secondary Retention Devices |

|

|

|

|

| |

|

|

|

|

|

| |

All 2007 and newer BOB Strollers have front forks which utilize secondary wheel retention |

|

|

| |||

devices designed to help keep the wheel from disengaging if the quick release is |

|

|

|

| ||

incorrectly adjusted. Secondary retention devices are not a substitute for correct quick |

|

|

| |||

release adjustment. The secondary retention devices on your stroller are the integral |

|

|

| |||

type that is formed into the outer faces of the front fork dropouts. |

|

|

|

|

| |

WARNING: Do not remove or disable secondary retention devices. As its name | Fig. 8 Fender Installation | Metal Tab Hole | ||||

implies, they serve as a |

|

|

| |||

not adjusted correctly, the secondary retention devices can reduce the risk of the | Brake | Cross Tube Hole |

| |||

wheel disengaging from the fork. Removing or disabling the secondary retention | Mounting |

|

| |||

devices may also void the warranty. |

|

|

| Plate Hole |

|

|

Secondary retention devices are not a substitute for correct quick release |

|

|

|

| ||

adjustment. Failure to properly adjust the quick release mechanism can cause |

|

|

|

| ||

the wheel to wobble or disengage, which could cause you to lose control and fall, |

|

| Fender | |||

resulting in serious injury or death. |

|

|

|

|

| Screw |

Installing a Quick Release Front Wheel: |

|

|

|

|

| |

|

|

|

|

|

| |

a. Move the quick release cam lever so that it curves away from the wheel (Fig. 9). This | Fabric |

|

| |||

Screw |

|

| ||||

is the FULLY OPEN position. |

|

|

| Hole |

|

|

b. Insert the wheel between the fork blades so that the axle seats firmly at the top of |

|

| Fender Hole |

| ||

the slots that are at the tips of the fork blades — the fork dropouts. The quick release |

|

|

| |||

cam lever should be on the left side of the stroller (Fig. 11 & 12). |

|

|

|

|

| |

c. Holding the quick release cam lever in the OPEN position with your right hand as |

| Tension |

|

| ||

shown in Fig. 11, tighten the tension adjusting nut with your left hand until it is finger |

| FULLY | ||||

tight against the fork dropout. |

|

|

| Adjusting |

| CLOSED |

d. While pushing the wheel firmly to the top of the slots in the fork dropouts, and at the | Nut |

|

| |||

same time centering the wheel rim in the fork, move the quick release cam lever |

|

|

|

| ||

upwards and swing it into the FULLY CLOSED position (Fig. 9 & 12). The lever should |

|

|

| |||

now be parallel to the fork blade and curved toward the wheel. To apply enough |

| (rotate to |

|

| ||

clamping force, you should have to wrap your fingers around the fork blade for |

|

|

| |||

leverage, and the quick release cam lever should leave a clear imprint in the palm | adjust |

|

| |||

of your hand. |

|

|

| clamping |

|

|

WARNING: Securely clamping the wheel takes considerable force. If you can fully | force) | Conical Springs |

| |||

|

| |||||

close the quick release without wrapping your fingers around the fork blade for |

|

|

| |||

leverage, and the quick release cam lever does not leave a clear imprint in the |

|

| Quick Release | FULLY | ||

palm of your hand, the tension is insufficient. Open the lever; turn the tension |

|

| Cam Lever | OPEN | ||

adjusting nut clockwise a quarter turn; then try again. |

|

|

|

|

| |

e. If the quick release cam lever cannot be pushed all the way to the fully closed position | Fig. 9 | Front Wheel Quick Release Anatomy. | ||||

parallel to the fork blade, return the lever to the OPEN position. Then turn the tension |

|

|

| |||

adjusting nut counterclockwise | Fig. 10 Caliper Brake Anatomy |

| ||||

Removing a Quick Release Front Wheel: |

|

|

| 10 mm Nut | ||

|

|

|

|

|

| |

a. To remove the front wheel, open the brake quick release (Fig. 10). |

|

| Barrel | Brake Body |

| |

|

| Adjuster |

| Brake & Fender | ||

b. Move the wheel’s | Lock |

| Mounting Screw | |||

to the FULLY OPEN position (Fig. 9). Your front fork has integral secondary |

|

|

| |||

| Nut |

|

| |||

retention devices. Loosen the tension adjusting nut enough to allow removing the |

|

|

| |||

|

|

|

| |||

wheel. |

|

|

| Brake |

|

|

c. Raise the front wheel a few inches off the ground and tap the top of the wheel with |

|

| ||||

the palm of your hand to knock the wheel out of the front fork. |

|

| Quick |

|

| |

|

|

|

| Release |

| Brake |

7. HAND BRAKE: |

|

|

| Lever |

| |

|

|

|

| Pad Nut | ||

|

|

|

|

| ||

The hand brake may be used to help slow or stop the stroller. |

|

|

|

|

| |

The hand brake is not a parking brake. (See section 8) |

|

|

|

|

| |

After installing the front wheel, the brake caliper will need to be placed in the closed |

|

|

|

| ||

position. Close the brake quick release lever (Fig. 10) by squeezing the brake pads |

|

|

|

| ||

against the wheel with one hand, then rotate the brake quick release lever in the counter |

|

|

| |||

clockwise direction with your other hand until |

| it |

|

|

| |

points downward. |

| Fork |

|

|

|

|

For the hand brake to work correctly, it is | Tension | Blade | Quick |

|

| |

critical that it be adjusted properly. Squeeze | Adjusting | Fork |

|

| ||

the brake lever and verify that the brake | Nut | Release |

|

| ||

pads contact the rim as shown in Fig. 15. |

| Dropouts | Cam Lever |

|

| |

If they are misaligned, use a 10mm wrench |

|

| Closed |

|

| |

to loosen brake pad nuts, slide pads into |

| Quick |

|

|

|

|

correct position and tighten securely. The |

| Release |

|

|

|

|

cable tension is |

| Cam |

|

|

|

|

yet the brake cable will need periodic |

| Lever |

|

|

| Fork |

adjustment (as the cable stretches slightly |

| Open |

|

|

| Blade |

and the black cable housing compresses | Fig. 11 Front fork dropouts shown |

|

|

|

| |

over time). To adjust cable tension, there |

|

| Fig. 12 Quick Release in the closed | |||

are two barrel adjusters in the brake | with wheel in position. Adjust nut snug |

|

| |||

assembly (Fig.10 & 13). To tighten the cable, | with Quick Release in open position. |

|

| position and parallel to fork blade. | ||

loosen the lock ring and turn the barrel |

|

| ||||

|

|

|

|

|

| |

OMS03A |

|

|

|

|

| P3 |