24I RSF specifications

Bosch Appliances has long been a leader in the home appliance market, known for its innovation, reliability, and cutting-edge technology. One of the standout products from Bosch is the 24I RSF, a highly regarded model that exemplifies the brand’s commitment to quality and performance in home kitchen solutions.The Bosch 24I RSF is a high-efficiency dishwasher designed to meet the needs of modern households. It features a sleek, compact design that is perfect for small kitchens or limited spaces without sacrificing capacity and functionality. With its 24-inch width, it seamlessly integrates into most kitchen environments while providing ample space for dishwashing needs.

One of the hallmark features of the Bosch 24I RSF is its incredible water and energy efficiency. Rated among the best in its class, this dishwasher uses sensors to detect how dirty the dishes are, automatically adjusting the wash cycle for optimal performance. This not only conserves water but also reduces energy consumption, making it an environmentally friendly choice for eco-conscious consumers.

The 24I RSF is also equipped with Bosch’s innovative PrecisionWash technology. This advanced system utilizes intelligent sensors to continually scan and adjust the wash cycle, ensuring all dishes are thoroughly cleaned, no matter their placement in the dishwasher. The powerful spray arms reach every corner and crevice, guaranteeing sparkling results every time.

In terms of user convenience, the Bosch 24I RSF comes with flexible loading options, including adjustable racks and a third rack for utensils, allowing users to efficiently optimize space. The Quiet operation, achieving noise levels as low as 44 decibels, makes it perfect for open-concept living spaces. Users can run dishwashing cycles even during quiet moments without disruption.

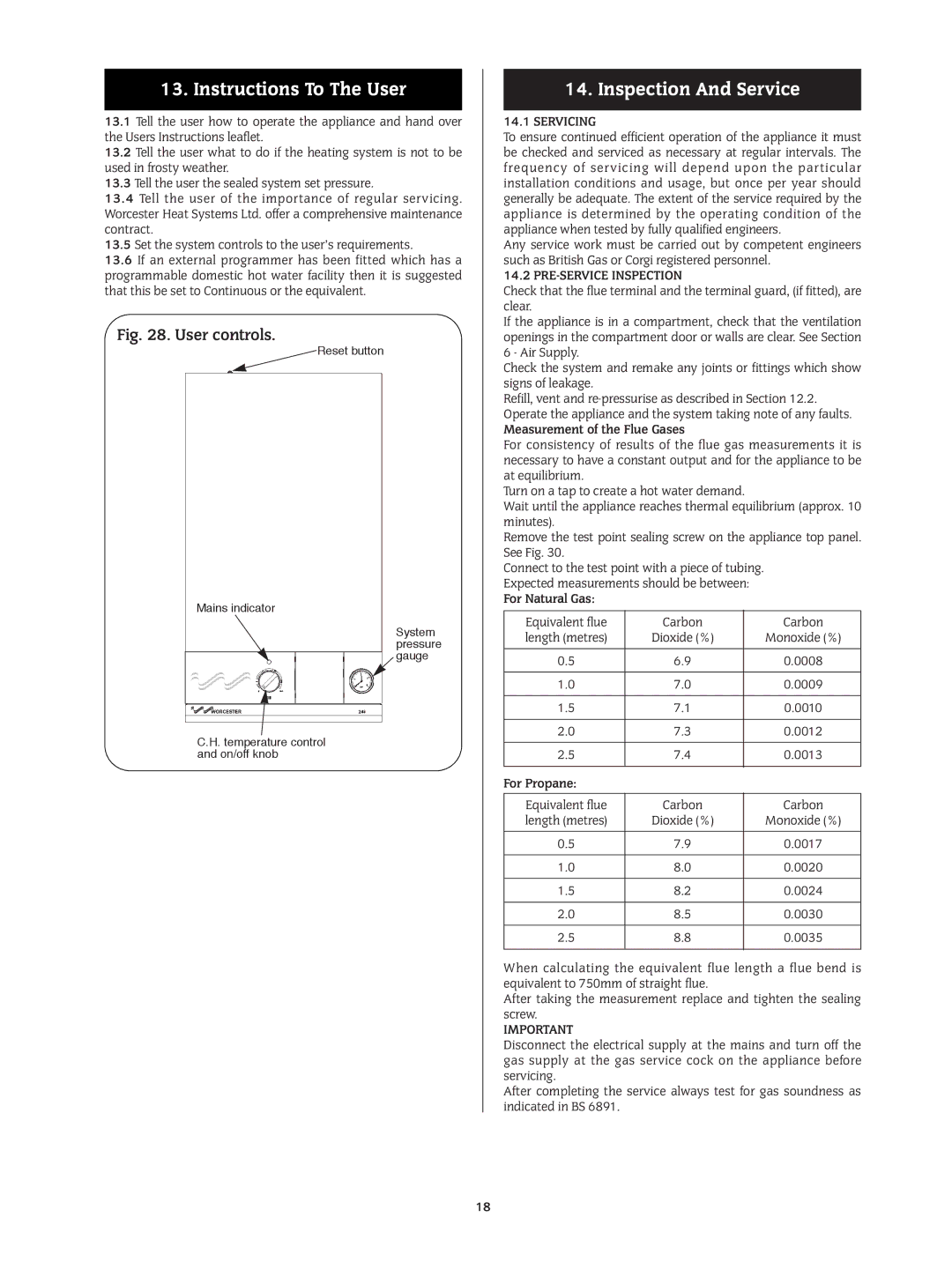

Another appealing characteristic of the Bosch 24I RSF is its simple user interface with a digital display, offering straightforward selections for the various wash cycles and options tailored to different types of loads. The self-cleaning filter system is an added convenience, reducing the need for maintenance.

Built with quality materials and robust engineering, the Bosch 24I RSF is not only reliable but also stylish, featuring a contemporary design that fits seamlessly into any kitchen decor. The combination of innovation, efficiency, and aesthetic appeal makes the Bosch 24I RSF an attractive choice for homeowners looking to elevate their kitchen experience. Its blend of features ensures exceptional cleaning performance while maintaining a commitment to sustainability, truly embodying the Bosch philosophy of creating appliances that improve everyday life.