1033VSR, 1013VSR, 1030VSR, 1011VSR, 1012VSR specifications

Bosch Power Tools is renowned for its commitment to quality and innovation in the field of power tools. Among its range, the Bosch 1034VSR, 1012VSR, 1011VSR, 1030VSR, and 1013VSR stand out as versatile and reliable options for both professional contractors and DIY enthusiasts.The Bosch 1034VSR is a powerful drill featuring an 8 amp motor, providing robust performance for drilling and fastening applications. One of its main features is the variable speed control that allows users to adjust the speed from 0 to 2,600 RPM, which enhances precision in drilling operations. Moreover, the 1034VSR incorporates a dual-mode switch that enables users to switch between hammer drilling and rotation-only modes, making it ideal for various materials, including masonry and wood.

The Bosch 1012VSR offers a slightly lower amp motor, around 7.5 amps, while still delivering reliable performance. This model is designed with a two-speed gearbox that allows users to select high torque for heavy-duty applications or high speed for lighter tasks, making it a versatile choice for different projects. Its lightweight design and ergonomic grip increase comfort during extended use, reducing user fatigue.

Similarly, the Bosch 1011VSR model integrates a 7.5 amp motor, but what sets it apart is its compact size, which enhances maneuverability in tight spaces. This drill features a keyless chuck, simplifying bit changes and enhancing workflow efficiency. Versatile and easy to handle, the 1011VSR is an excellent option for professionals needing a dependable drilling solution in constrained environments.

The Bosch 1030VSR is engineered for demanding applications that require both performance and durability. Boasting an electronic control system, it sustains consistent performance throughout the operation. This model also includes a built-in LED light, illuminating workspaces even in low-light conditions, enhancing safety and accuracy.

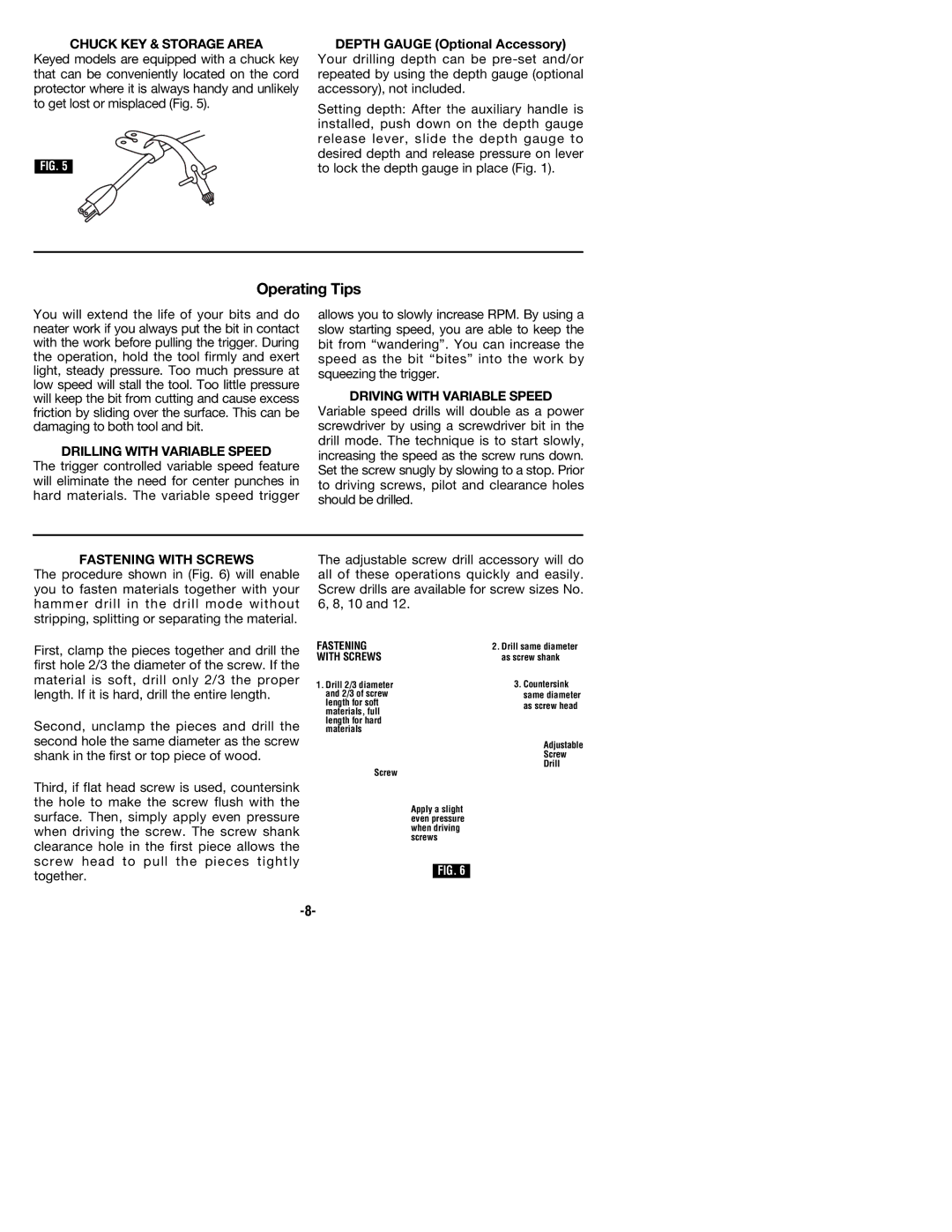

Lastly, the Bosch 1013VSR blends performance with convenience. It features a soft-grip handle designed for comfort, allowing users to maintain control during extended use. This drill also includes an integrated depth gauge, facilitating precise drilling depths for accurate installations.

Overall, the Bosch 1034VSR, 1012VSR, 1011VSR, 1030VSR, and 1013VSR are stellar examples of Bosch's dedication to performance, durability, and user-friendly design. With their innovative technologies and features tailored to meet a variety of drilling needs, these tools are excellent additions to any professional or DIY toolkit.