BM 1619929800

Operating Instructions

VARIABLE SPEED CONTROLLED

TRIGGER SWITCH

Your tool is equipped with a variable speed trigger switch. The tool can be turned "ON" or "OFF" by squeezing or releasing the trigger. The speed can be adjusted from the minimum to maximum nameplate RPM by the pressure you apply to the trigger. Apply more pressure to increase the speed and release pressure to decrease speed Fig. 1).

!WARNING To reduce the risk of injury immediately discontinue use

of the tool if the variable speed control ceases to function. Subsequent loss of on/off control of the trigger switch is likely.

FORWARD/REVERSING LEVER &

TRIGGER LOCK

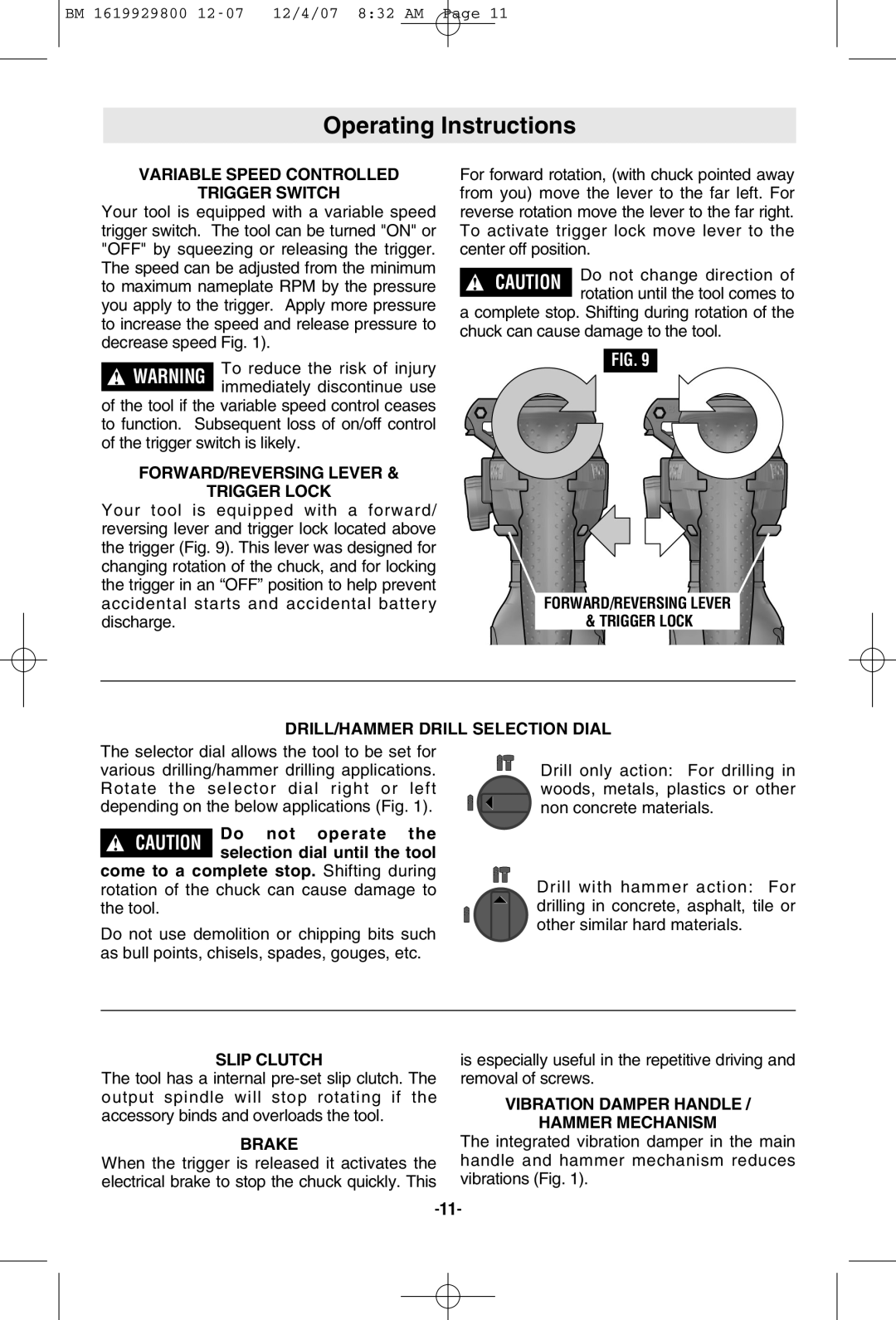

Your tool is equipped with a forward/ reversing lever and trigger lock located above the trigger (Fig. 9). This lever was designed for changing rotation of the chuck, and for locking the trigger in an “OFF” position to help prevent accidental starts and accidental battery discharge.

For forward rotation, (with chuck pointed away from you) move the lever to the far left. For reverse rotation move the lever to the far right. To activate trigger lock move lever to the center off position.

!CAUTION Do not change direction of rotation until the tool comes to

a complete stop. Shifting during rotation of the chuck can cause damage to the tool.

FIG. 9

FORWARD/REVERSING LEVER

& TRIGGER LOCK

DRILL/HAMMER DRILL SELECTION DIAL

The selector dial allows the tool to be set for various drilling/hammer drilling applications. Rotate the selector dial right or left depending on the below applications (Fig. 1).

!CAUTION Do not operate the selection dial until the tool

come to a complete stop. Shifting during rotation of the chuck can cause damage to the tool.

Do not use demolition or chipping bits such as bull points, chisels, spades, gouges, etc.

Drill only action: For drilling in woods, metals, plastics or other non concrete materials.

Drill with hammer action: For drilling in concrete, asphalt, tile or other similar hard materials.

SLIP CLUTCH

The tool has a internal

BRAKE

When the trigger is released it activates the electrical brake to stop the chuck quickly. This

is especially useful in the repetitive driving and removal of screws.

VIBRATION DAMPER HANDLE /

HAMMER MECHANISM

The integrated vibration damper in the main handle and hammer mechanism reduces vibrations (Fig. 1).