BM 2609140447

SANDING AND POLISHING

Fine sanding and polishing require “touch”. Select the most efficient speed.

When using polishing bonnets, alway be sure the excess string that secures the bonnet is tucked well within the bonnet during operation.

RUNNING NUTS AND BOLTS

Variable speed control must be used with caution for driving nuts and bolts with socket set attachments. The technique is to start slowly, increasing speed as the nut or bolt runs down. Set the nut or bolt snugly by slowing the drill to a stop. If this procedure is not followed, the tool will have a tendency to torque or twist in your hands when the nut or bolt seats.

WIRE BRUSHES

Work with brushes requires high speeds.

BRUSHING PRESSURE

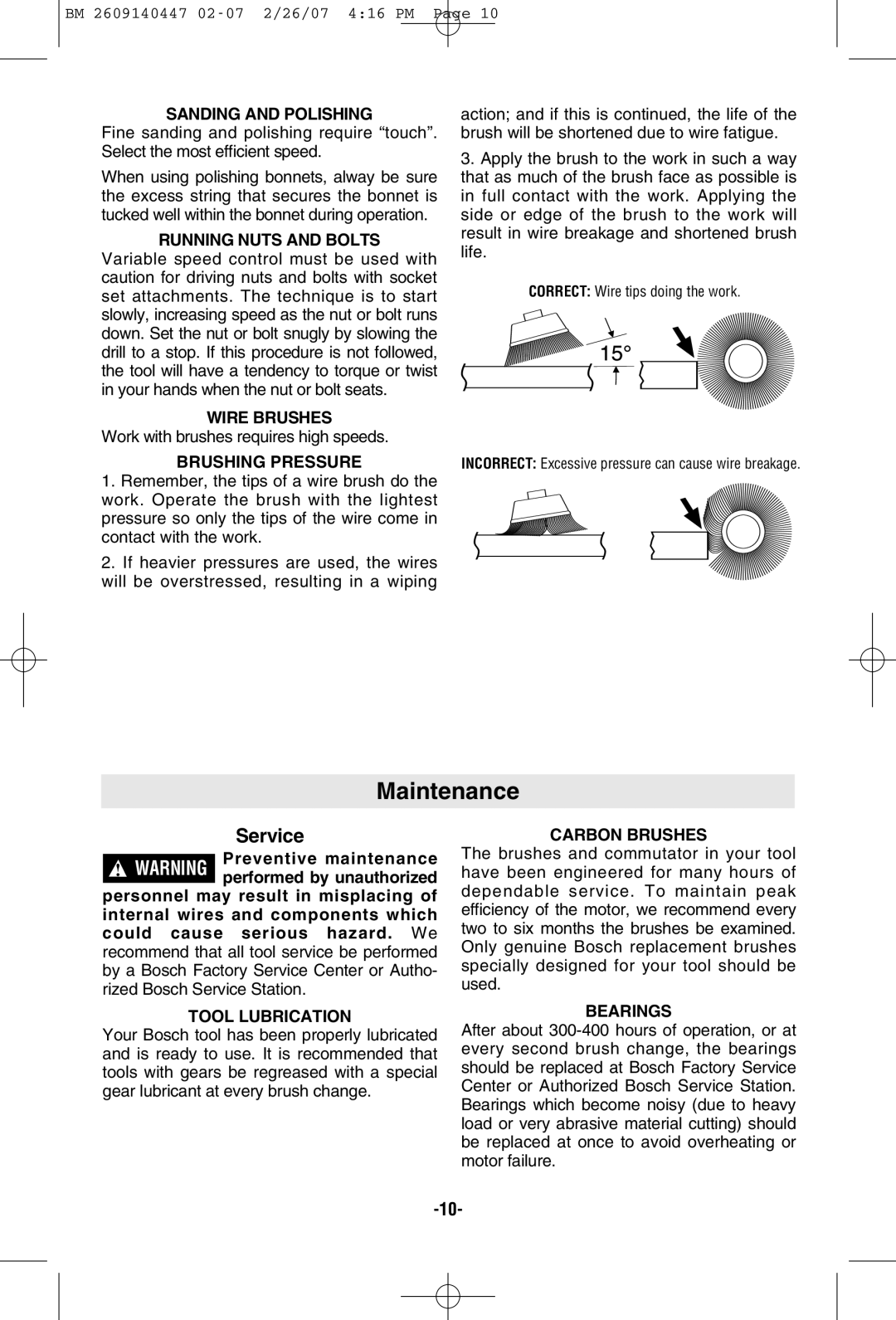

1.Remember, the tips of a wire brush do the work. Operate the brush with the lightest pressure so only the tips of the wire come in contact with the work.

2.If heavier pressures are used, the wires will be overstressed, resulting in a wiping

action; and if this is continued, the life of the brush will be shortened due to wire fatigue.

3.Apply the brush to the work in such a way that as much of the brush face as possible is in full contact with the work. Applying the side or edge of the brush to the work will result in wire breakage and shortened brush life.

CORRECT: Wire tips doing the work.

INCORRECT: Excessive pressure can cause wire breakage.

Maintenance

Service

Preventive maintenance ! WARNING performed by unauthorized personnel may result in misplacing of internal wires and components which could cause serious hazard. We recommend that all tool service be performed by a Bosch Factory Service Center or Autho-

rized Bosch Service Station.

TOOL LUBRICATION

Your Bosch tool has been properly lubricated and is ready to use. It is recommended that tools with gears be regreased with a special gear lubricant at every brush change.

CARBON BRUSHES

The brushes and commutator in your tool have been engineered for many hours of dependable service. To maintain peak efficiency of the motor, we recommend every two to six months the brushes be examined. Only genuine Bosch replacement brushes specially designed for your tool should be used.

BEARINGS

After about