Double Insulated Tools

•Double Insulation is a design concept used in electric power tools which eliminates the need for the three wire grounded power cord and grounded power supply system. It is a recog- nized and approved system by Underwriter’s Laboratories, CSA and Federal OSHA authori- ties.

IMPORTANT: Servicing of a tool with double insulation requires care and knowledge of the system and should be performed only by a qualified service technician. WHEN SER-

VICE IS REQUIRED USE ONLY IDENTI- CAL REPLACEMENT PARTS.

POLARIZED PLUGS: If your tool is equipped with a polarized plug (one blade is wider than the other), this plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper outlet. To reduce the risk of electric shock do not change the plug in any way.

Extension Cords

•Replace damaged cords immediately. Use of damaged cords can shock, burn or electrocute.

•If an extension cord is necessary, a cord with adequate size conductors should be used to prevent excessive voltage drop, loss of power or overheating. The table below shows the correct size to use, depending on cord length and amperage rating on the tool’s nameplate. If in doubt, use the next heavier gauge. Always use U.L. and CSA listed extension cords.

|

| Ampere Rating (shown on nameplate) | ||||||

|

| 0- | 2.1- | 3.5- | 5.1- | 7.1- | 12.1- | |

|

| 2.0 | 3.4 | 5.0 | 7.0 | 12.0 | 16.0 | |

Length |

|

|

|

|

|

|

| |

25' | 18 | 18 | 18 | 18 | 16 | 14 | ||

50' | 18 | 18 | 16 | 16 | 14 | 12 | ||

| ||||||||

Cord | 75' | 18 | 18 | 16 | 14 | 12 | 10 | |

100' | 18 | 16 | 14 | 12 | 10 |

| ||

|

| |||||||

| 150' | 16 | 14 | 12 | 12 | Wire Gauge | ||

Note: Thesmallerthegaugenumber,thelarger the wire is in the cord.

"SAVE THESE INSTRUCTIONS"

Operating the Tool

"Tri-Control" Paddle Switch

Models 1209 & 1214

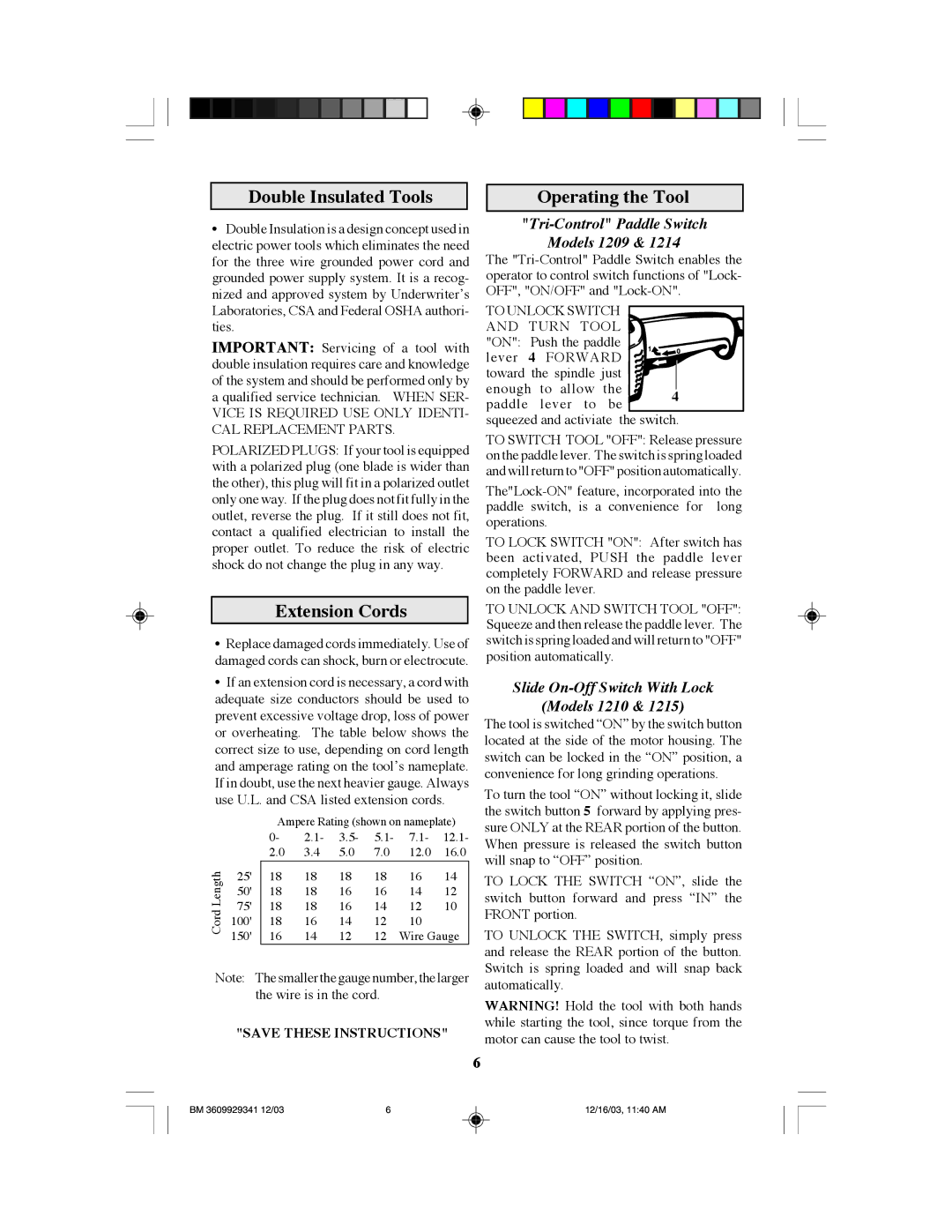

The

TO UNLOCK SWITCH |

|

| |||

AND TURN TOOL |

|

| |||

"ON": Push the paddle | 1 | 0 | |||

lever 4 | FORWARD | ||||

| |||||

|

| ||||

toward the spindle just |

|

| |||

enough | to allow | the |

| 4 | |

paddle | lever to | be |

| ||

| 10 | ||||

squeezed and activiate the switch.

TO SWITCH TOOL "OFF": Release pressure on the paddle lever. The switch is spring loaded andwillreturnto"OFF"positionautomatically.

TO LOCK SWITCH "ON": After switch has been activated, PUSH the paddle lever completely FORWARD and release pressure on the paddle lever.

TO UNLOCK AND SWITCH TOOL "OFF": Squeeze and then release the paddle lever. The switch is spring loaded and will return to "OFF" position automatically.

Slide On-Off Switch With Lock

(Models 1210 & 1215)

The tool is switched “ON” by the switch button located at the side of the motor housing. The switch can be locked in the “ON” position, a convenience for long grinding operations.

To turn the tool “ON” without locking it, slide the switch button 5 forward by applying pres- sure ONLY at the REAR portion of the button. When pressure is released the switch button will snap to “OFF” position.

TO LOCK THE SWITCH “ON”, slide the switch button forward and press “IN” the FRONT portion.

TO UNLOCK THE SWITCH, simply press and release the REAR portion of the button. Switch is spring loaded and will snap back automatically.

WARNING! Hold the tool with both hands while starting the tool, since torque from the motor can cause the tool to twist.

6

BM 3609929341 12/03 | 6 | 12/16/03, 11:40 AM |