BM 2610914845 3/03 3/18/03 10:56 AM Page 10

recharge will be lower. Normal capacity will be restored in two or three charge/discharge cycles. Remember to unplug charger during storage period.

5.If battery does not charge properly:

a.Check for voltage at outlet by plugging in some other electrical device.

b.Check to see if outlet is connected to a light switch which turns power “off” when lights are turned off.

c. Check battery pack terminals for dirt. Clean with cotton swab and alcohol if necessary.

d. If you still do not get proper charging, take or send tool, battery pack and charger to your local Bosch Service Center. See “Tools, Electric” in the Yellow Pages for names and addresses.

Note: Use of chargers or battery packs not sold by Bosch may void the warranty.

DRILLING WOOD OR PLASTIC

If backing block is not used, ease up on the pressure just before the bit breaks through the wood to avoid splintering. Complete the hole from the opposite side immediately after the point breaks through. If bit binds, reverse the drilling operation to help remove the bit from the work.

DRILLING METAL

Make a center punch in the material for easier starting. Use enough pressure to keep the bit cutting. If the bit is allowed to merely

spin in the hole, it will become dull within a short time. When drilling a larger hole, it is faster and easier on your power pack to first make a smaller hole and enlarge it to the required size. Lubricate the tip of the bit occasionally with CUTTING OIL for easier metal drilling. If bit binds, reverse the drilling to help remove the bit from the work.

It is not recommended to drill holes larger than 1/2" diameter through soft steel thicker than 1/8". Drilling through metal rapidly drains energy from your power pack.

DRILLING MASONRY

Use

material being drilled. Soft materials require less pressure while the hard materials need more pressure to prevent the drill bit from spinning.

FASTENING WITH SCREWS

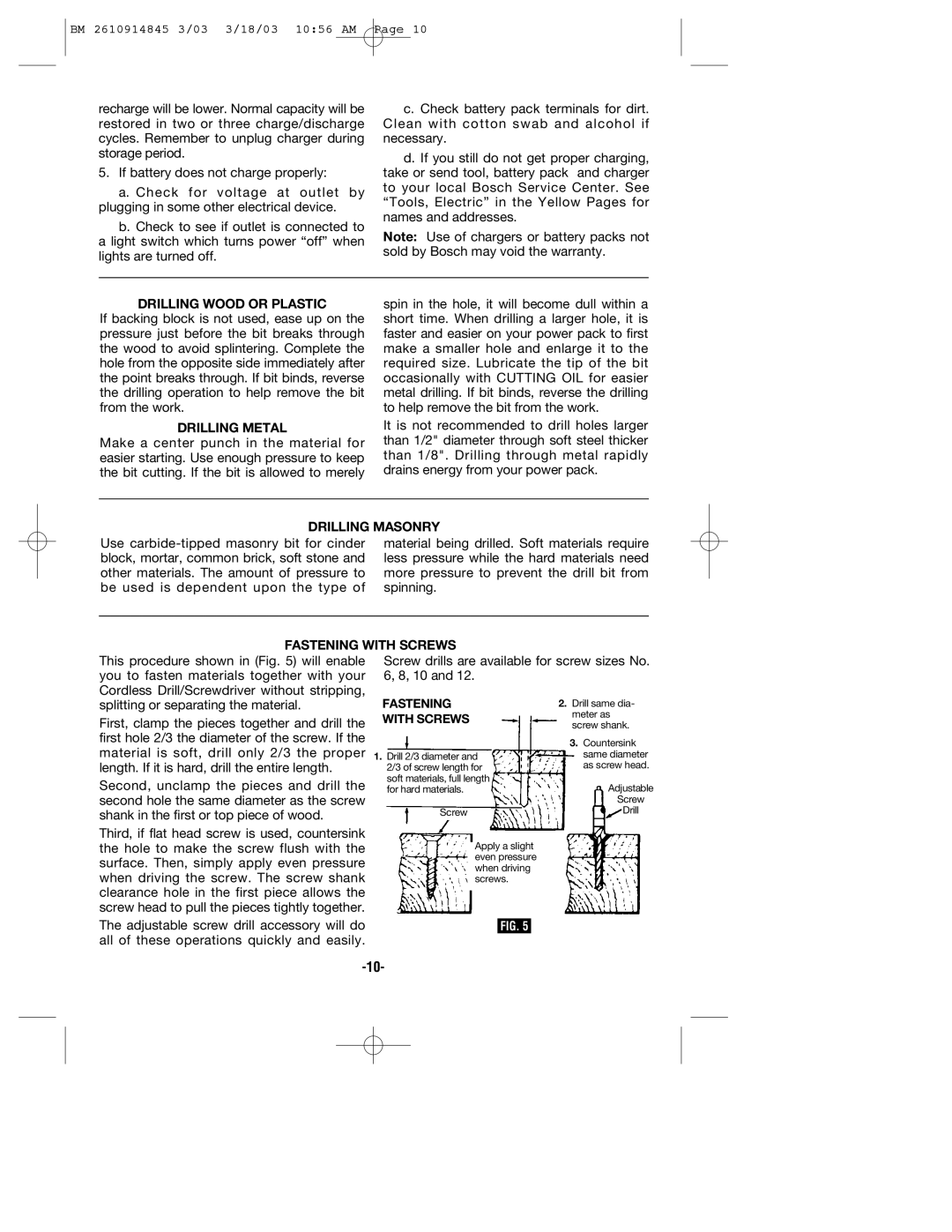

This procedure shown in (Fig. 5) will enable you to fasten materials together with your Cordless Drill/Screwdriver without stripping,

Screw drills are available for screw sizes No. 6, 8, 10 and 12.

splitting or separating the material.

First, clamp the pieces together and drill the first hole 2/3 the diameter of the screw. If the material is soft, drill only 2/3 the proper length. If it is hard, drill the entire length.

Second, unclamp the pieces and drill the second hole the same diameter as the screw shank in the first or top piece of wood.

Third, if flat head screw is used, countersink the hole to make the screw flush with the surface. Then, simply apply even pressure when driving the screw. The screw shank clearance hole in the first piece allows the screw head to pull the pieces tightly together.

FASTENING

WITH SCREWS

1.Drill 2/3 diameter and 2/3 of screw length for soft materials, full length for hard materials.

Screw

Apply a slight even pressure when driving screws.

2.Drill same dia- meter as screw shank.

3.Countersink same diameter as screw head.

Adjustable

Screw

Drill

The adjustable screw drill accessory will do all of these operations quickly and easily.

FIG. 5