BM 2610967904 1/03 1/15/03 2:57 PM Page 9

Operating Instructions

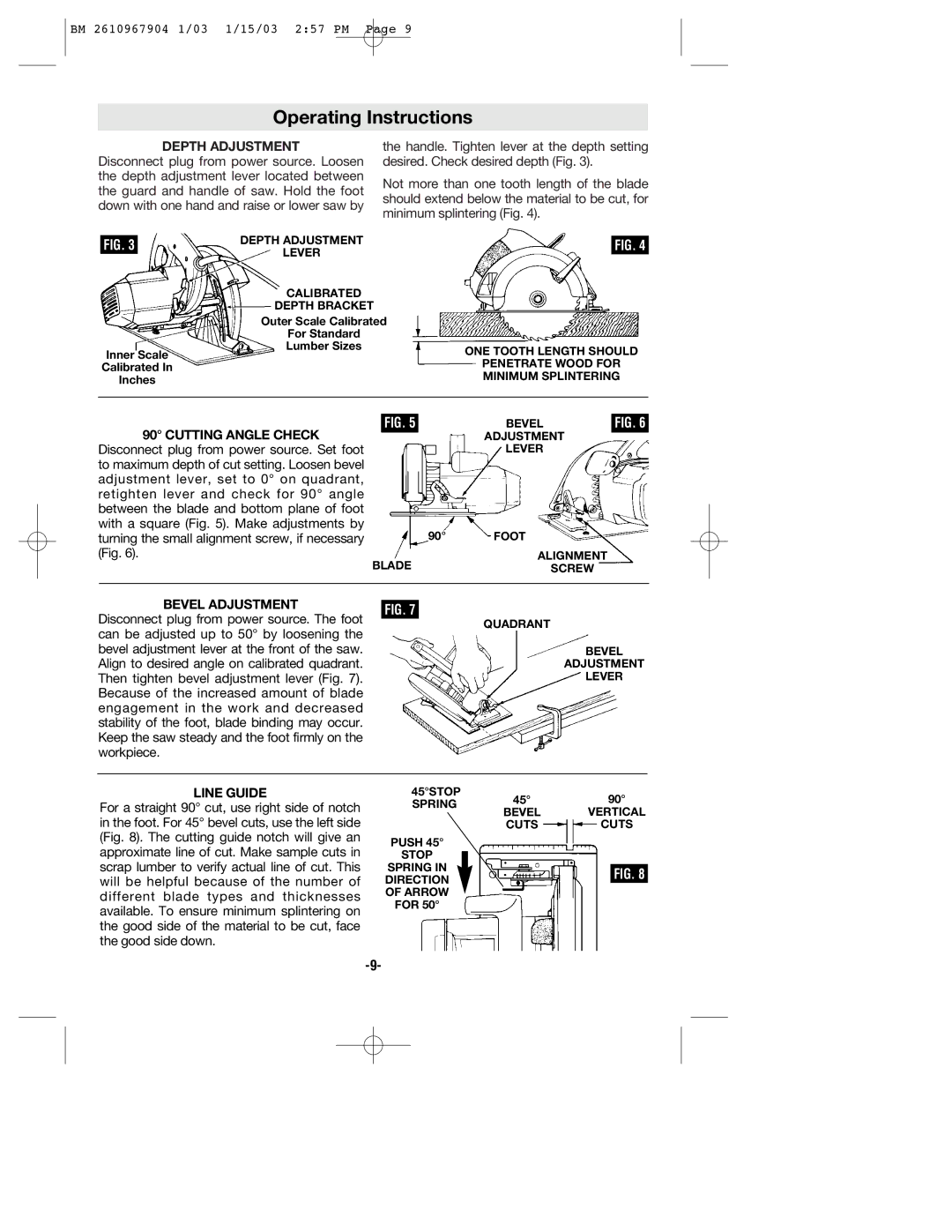

DEPTH ADJUSTMENT

Disconnect plug from power source. Loosen the depth adjustment lever located between the guard and handle of saw. Hold the foot down with one hand and raise or lower saw by

the handle. Tighten lever at the depth setting desired. Check desired depth (Fig. 3).

Not more than one tooth length of the blade should extend below the material to be cut, for minimum splintering (Fig. 4).

| FIG. 3 |

| DEPTH ADJUSTMENT |

| FIG. 4 |

|

| LEVER |

| ||

|

|

|

|

| |

|

|

| CALIBRATED |

|

|

|

|

| DEPTH BRACKET |

|

|

|

|

| Outer Scale Calibrated |

|

|

|

|

| For Standard |

|

|

| Inner Scale | Lumber Sizes | ONE TOOTH LENGTH SHOULD | ||

|

| ||||

|

| PENETRATE WOOD FOR | |||

| Calibrated In |

| |||

| Inches |

| MINIMUM SPLINTERING | ||

|

|

|

| ||

|

|

|

|

|

|

90° CUTTING ANGLE CHECK

Disconnect plug from power source. Set foot to maximum depth of cut setting. Loosen bevel adjustment lever, set to 0° on quadrant, retighten lever and check for 90° angle between the blade and bottom plane of foot with a square (Fig. 5). Make adjustments by turning the small alignment screw, if necessary (Fig. 6).

FIG. 5BEVELFIG. 6

ADJUSTMENT

LEVER

90° | FOOT | |

|

| ALIGNMENT |

BLADE |

| SCREW |

BEVEL ADJUSTMENT | FIG. 7 | |

Disconnect plug from power source. The foot | ||

| ||

can be adjusted up to 50° by loosening the |

| |

bevel adjustment lever at the front of the saw. |

| |

Align to desired angle on calibrated quadrant. |

| |

Then tighten bevel adjustment lever (Fig. 7). |

| |

Because of the increased amount of blade |

| |

engagement in the work and decreased |

| |

stability of the foot, blade binding may occur. |

| |

Keep the saw steady and the foot firmly on the |

| |

workpiece. |

|

QUADRANT

BEVEL

ADJUSTMENT

LEVER

LINE GUIDE

For a straight 90° cut, use right side of notch in the foot. For 45° bevel cuts, use the left side (Fig. 8). The cutting guide notch will give an approximate line of cut. Make sample cuts in scrap lumber to verify actual line of cut. This will be helpful because of the number of different blade types and thicknesses available. To ensure minimum splintering on the good side of the material to be cut, face the good side down.

45°STOP | 45° | 90° | |||

SPRING | |||||

| BEVEL | VERTICAL | |||

|

| ||||

|

| CUTS | CUTS | ||

PUSH 45° |

|

|

|

| |

STOP |

|

|

|

| |

|

|

|

| ||

SPRING IN |

|

|

|

| |

|

|

| FIG. 8 | ||

|

|

| |||

DIRECTION |

|

|

| ||

OF ARROW |

|

|

|

| |

FOR 50° |

|

|

|

| |