BM 1609929A20 3/03 3/12/03 10:35 AM Page 8

SIDE HANDLE

The side handle used to guide and balance the tool can be threaded into the front housing on either side, and on top of the tool, depending on personal preference and comfort. Use the side handle for safe control and ease of operation.

CUP GRINDING WHEELS

Use cup grinding wheels for

ADJUSTABLE CUP

WHEEL GUARD INSTALLATION

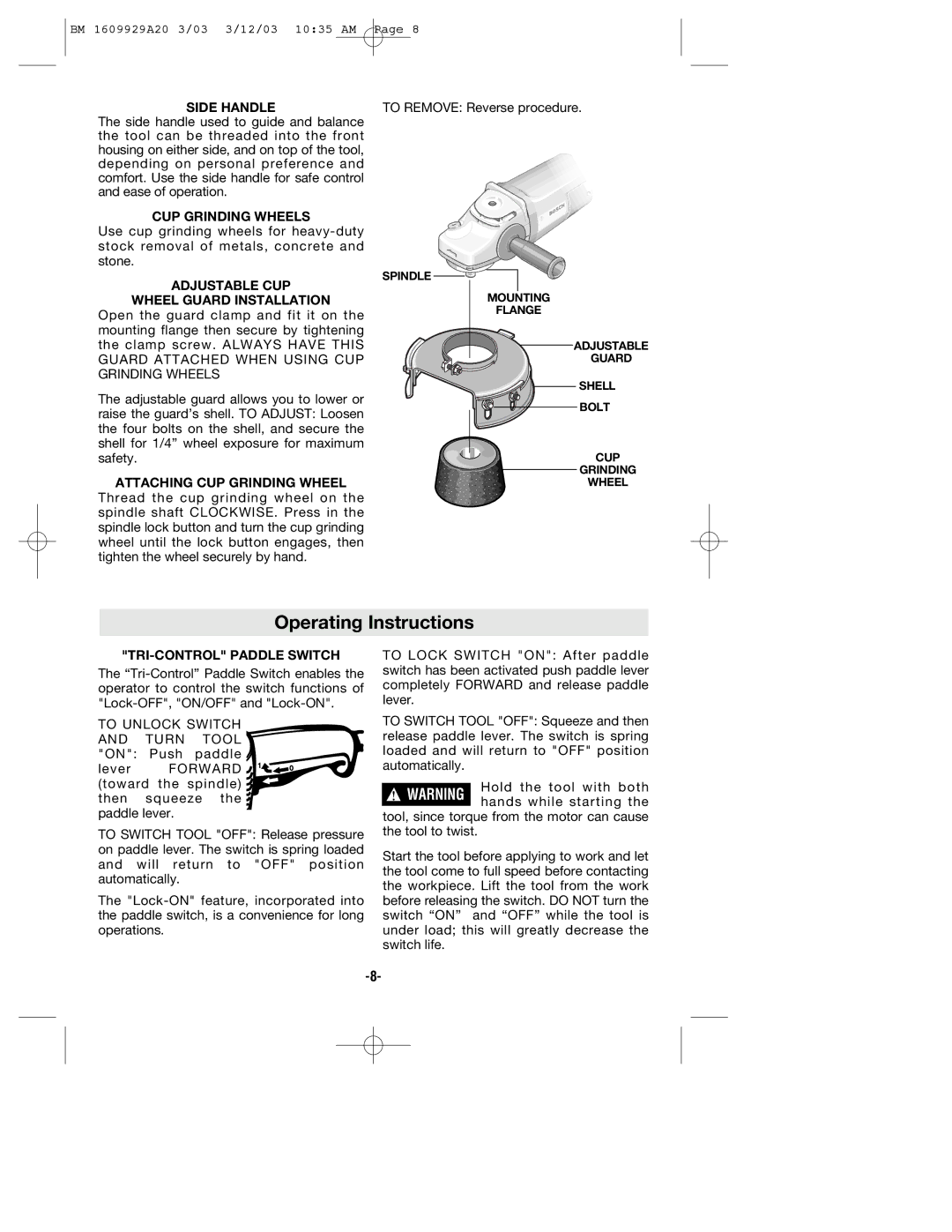

Open the guard clamp and fit it on the mounting flange then secure by tightening the clamp screw. ALWAYS HAVE THIS GUARD ATTACHED WHEN USING CUP GRINDING WHEELS

The adjustable guard allows you to lower or raise the guard’s shell. TO ADJUST: Loosen the four bolts on the shell, and secure the shell for 1/4” wheel exposure for maximum safety.

ATTACHING CUP GRINDING WHEEL

Thread the cup grinding wheel on the spindle shaft CLOCKWISE. Press in the spindle lock button and turn the cup grinding wheel until the lock button engages, then tighten the wheel securely by hand.

TO REMOVE: Reverse procedure.

SPINDLE ![]()

![]()

MOUNTING

FLANGE

ADJUSTABLE

GUARD

SHELL

BOLT

CUP

GRINDING

WHEEL

Operating Instructions

"TRI-CONTROL" PADDLE SWITCH

The

TO UNLOCK SWITCH |

|

| ||

AND | TURN | TOOL |

|

|

"ON": | Push | paddle |

|

|

lever | FORWARD | 1 | 0 | |

| ||||

(toward the | spindle) |

|

| |

then | squeeze the |

|

| |

paddle lever. |

|

|

| |

TO SWITCH TOOL "OFF": Release pressure on paddle lever. The switch is spring loaded and will return to "OFF" position automatically.

The

TO LOCK SWITCH "ON": After paddle switch has been activated push paddle lever completely FORWARD and release paddle lever.

TO SWITCH TOOL "OFF": Squeeze and then release paddle lever. The switch is spring loaded and will return to "OFF" position automatically.

!WARNING Hold the tool with both hands while starting the

tool, since torque from the motor can cause the tool to twist.

Start the tool before applying to work and let the tool come to full speed before contacting the workpiece. Lift the tool from the work before releasing the switch. DO NOT turn the switch “ON” and “OFF” while the tool is under load; this will greatly decrease the switch life.