BM 1609929Y07 10-10:BM 1609929Y07 10-10 1/18/11 10:06 AM Page 11

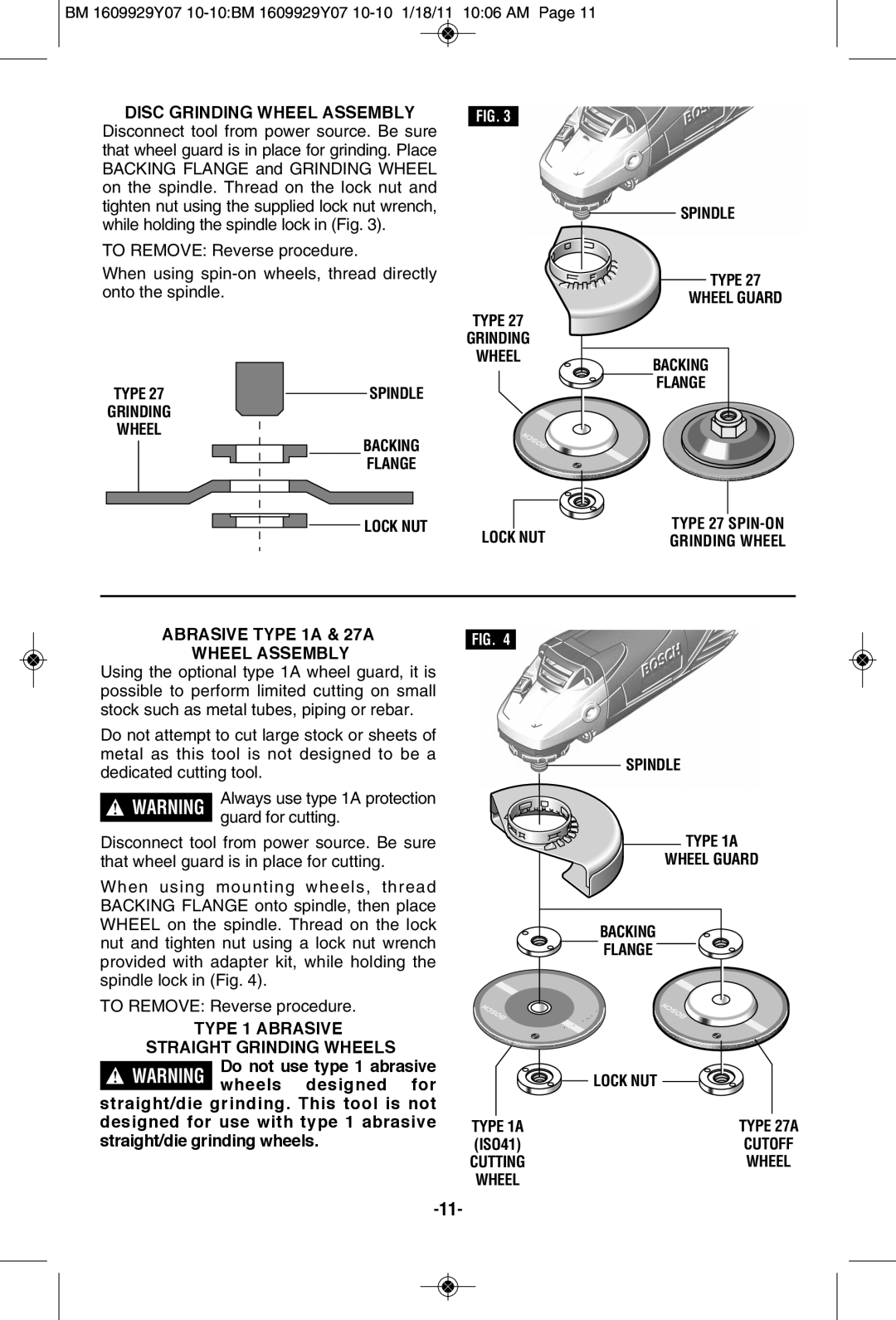

DISC GRINDING WHEEL ASSEMBLY

Disconnect tool from power source. Be sure that wheel guard is in place for grinding. Place BACKING FLANGE and GRINDING WHEEL on the spindle. Thread on the lock nut and tighten nut using the supplied lock nut wrench, while holding the spindle lock in (Fig. 3).

TO REMOVE: Reverse procedure.

When using

TYPE 27 |

|

|

|

|

| SPINDLE | ||

|

|

|

|

| ||||

GRINDING |

|

|

|

|

|

| ||

WHEEL |

|

|

|

| BACKING | |||

|

|

|

|

|

|

| ||

|

|

|

| |||||

|

|

|

|

|

|

| FLANGE | |

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FIG. 3

TYPE 27

GRINDING

WHEEL

SPINDLE

TYPE 27

WHEEL GUARD

BACKING

FLANGE

![]()

![]()

![]()

![]()

![]() LOCK NUT

LOCK NUT

LOCK NUT

TYPE 27

ABRASIVE TYPE 1A & 27A

WHEEL ASSEMBLY

Using the optional type 1A wheel guard, it is possible to perform limited cutting on small stock such as metal tubes, piping or rebar.

Do not attempt to cut large stock or sheets of metal as this tool is not designed to be a dedicated cutting tool.

! WARNING | Always use type 1A protection |

| guard for cutting. |

|

Disconnect tool from power source. Be sure that wheel guard is in place for cutting.

When using mounting wheels, thread BACKING FLANGE onto spindle, then place WHEEL on the spindle. Thread on the lock nut and tighten nut using a lock nut wrench provided with adapter kit, while holding the spindle lock in (Fig. 4).

TO REMOVE: Reverse procedure.

TYPE 1 ABRASIVE

STRAIGHT GRINDING WHEELS

Do not use type 1 abrasive ! WARNING wheels designed for

straight/die grinding. This tool is not designed for use with type 1 abrasive straight/die grinding wheels.

FIG. 4

SPINDLE

TYPE 1A

WHEEL GUARD

BACKING

FLANGE

| LOCK NUT |

TYPE 1A | TYPE 27A |

(ISO41) | CUTOFF |

CUTTING | WHEEL |

WHEEL |

|